If you work in aggregate or mining, you’ve probably asked what is gravel screen mesh used for. You use mesh to separate, sort, and grade gravel and other materials. Mesh helps you remove unwanted debris and get the right size for your project. When you run screening equipment, the mesh keeps your aggregate clean and ready for use. This process saves you time and improves your results.

Key Takeaways

- Gravel screen mesh sorts materials by size. This helps you get the right kind for your job.

- Picking the right mesh size saves time. It also cuts down on waste. You get more useful aggregate.

- Vibrating screens help sort things faster. They also make sorting more accurate.

- Taking care of your mesh often makes it last longer. It also helps the screen work better.

- Different jobs, like quarry grading or recycled aggregate screening, need special mesh designs.

- Picking the right mesh size and type is very important. It helps with dewatering and stops clogging.

- Stable grading keeps product quality the same. This is very important for building and landscaping jobs.

- Buying good screening media means less downtime. It also helps your work run better.

What Is Gravel Screen Mesh Used For

Mesh Function in Screening

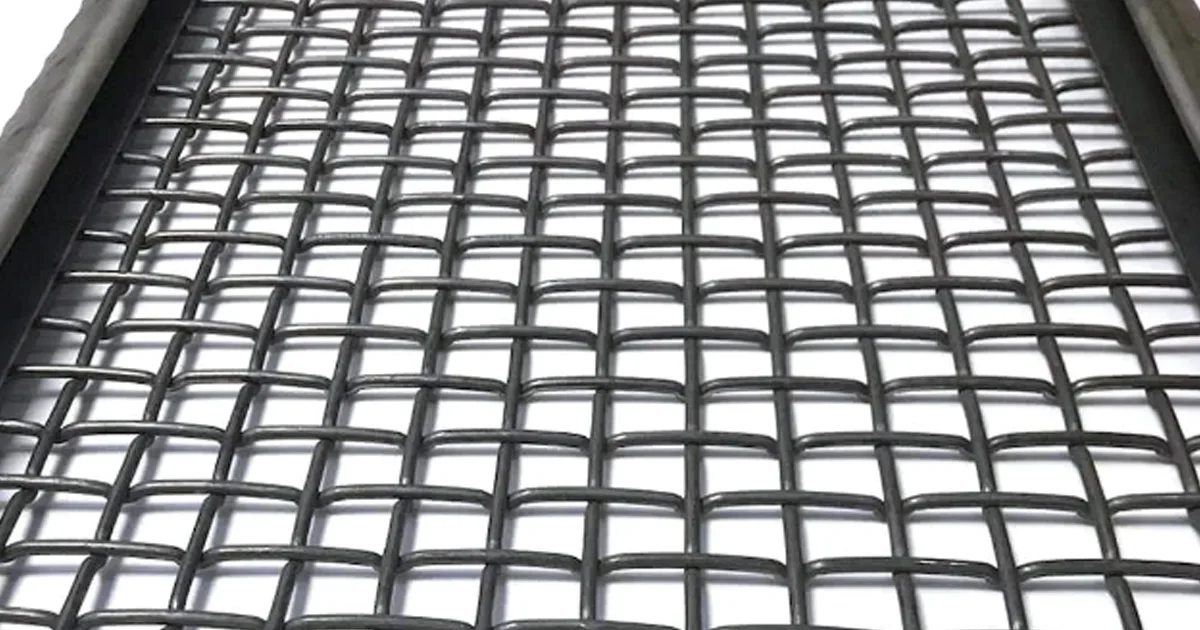

You might wonder what is gravel screen mesh used for when you see piles of rocks and sand at a quarry. Mesh acts like a filter in your screening system. It separates materials by size, letting smaller pieces fall through while holding back larger chunks. When you feed gravel or sand onto the screen, the mesh catches the big stuff and lets the fine particles pass. This process helps you sort out what you need for your project. You can use different mesh sizes to get the exact grade you want. If you need clean sand for concrete or larger stones for drainage, the mesh makes it easy to pick out the right material.

Tip: Using the right mesh size in your screening system can save you time and reduce waste. You get more usable aggregate and less debris.

Role in Aggregate Production

In the aggregate processing industry, you rely on screens to keep your material consistent. After crushing rocks, you use a screening system to sort gravel, sand, and crushed stone. The mesh helps you grade these materials so you can meet customer specs. You might use several decks with different mesh sizes. The top deck catches the biggest pieces, and each lower deck sorts out finer grades. This setup improves material quality and protects your equipment from oversized rocks. You also boost your yield because the mesh keeps your product clean and ready for use.

Here are some key processes where you use gravel screen mesh:

- Mining and mineral processing

- Rock, sand, and gravel production

- Compound feed sorting

- Recycling operations

When you ask what is gravel screen mesh used for, think about how it helps you achieve clean-grade separation and optimize your material grading. You get better results and more consistent products.

Vibrating Screen Operation

Your screening system often uses vibrating screens to make sorting faster and more efficient. The screen shakes or vibrates, moving gravel and sand across the mesh. This action helps separate particles by size. Larger pieces fall through bigger openings, while smaller ones stay on top or pass through finer mesh. You can adjust the vibration and the angle of the screen to get the best separation. If you use the right mesh and settings, you improve your screening operations and keep your aggregate clean.

The mesh size plays a big role in how well your screening system works. Smaller mesh holes are great for fine powders, while larger openings suit big aggregates. If you increase the mesh size, you can boost throughput, but you might lose some accuracy. You need to find the right balance for your material. Heavy or oddly shaped particles may need special mesh sizes to avoid clogging and get good separation.

| Mesh Size | Material Type | Throughput | Accuracy |

|---|---|---|---|

| Small | Fine sand, powder | Low | High |

| Medium | Gravel, crushed | Medium | Medium |

| Large | Big rocks | High | Low |

When you run your screening system, you want to keep your operations smooth and efficient. The right mesh and vibration settings help you sort gravel and sand quickly, reduce downtime, and deliver top-quality aggregate.

Applications of Gravel Screen Mesh

Quarry Grading

If you work with stone, you see quarry grading often. The screen mesh is very important in this process. You use more than one layer of screens to sort rocks by size. Each layer matches a certain size of rock or sand. This helps you get the best results for grading. You can change the mesh design to fit your needs. This way, you always get the right size for each job.

Here’s a simple look at how quarry grading uses screen mesh:

| Aspect | Description |

|---|---|

| Applications | Using more than one layer of screen mesh helps sort rocks better and faster in quarries. |

| Engineering Experience | Shows how to match each screen mesh layer to the right size of rock for the best sorting. |

| Structural Principles | Talks about making and changing mesh designs for special jobs. |

| Maintenance Suggestions | Gives tips on how to take care of the mesh so it works well and lasts longer. |

| Economic Benefits | Helps companies get better results and save money in construction work. |

You want your screens to work well all the time. If you check and fix your mesh often, it will last longer. This means less time fixing things and better results for your business.

Sand & Gravel Lines

You use gravel screen mesh in sand and gravel lines to get clean material. Strong screens sort the rocks and sand into different sizes. Sorting is very important. If your screens do not work right, you lose time and your product is not as good.

- You sort rocks and sand into different sizes and grades. This makes your final product better.

- You take out dirt and control the size of the pieces to meet your needs.

- You use bar feeding screens and soil removing screens together to make your sand and gravel even cleaner.

You should not put too much on the screens at once. Using more than one layer works best. Pick square holes for your mesh and make sure the size is right for your material. Check your screens often and change them when they get old. This keeps your line working well.

Scalping Before Crushing

At the start, big scalping screens take out small pieces before the main crusher. This helps protect the crusher from rough rocks or sand that are already the right size. If you skip this step, the crusher wears out faster and needs more repairs.

You use this step to save money and time. Scalping with the right mesh helps your crusher last longer. Your work goes faster and you do not have to fix things as much. You get better rocks and less trouble with repairs.

Construction Aggregate Sizing

You want your construction projects to last and stay strong. That starts with using the right size of aggregate. Gravel screen mesh helps you sort and size your materials before you use them. When you run your material over the screen, you separate out the pieces that are too big or too small. This makes your concrete or road base much better.

Efficient resource utilization in construction starts with the careful sorting and sizing of materials through screening, ensuring that only appropriately sized particles are used, which minimizes waste and optimizes resource allocation.

You can trust your screening process to give you a steady supply of the right aggregate. This means you do not waste material or money. You also avoid problems with your finished project.

Proper material screening is essential for enhancing the structural integrity of construction projects, as it ensures that aggregates are of the correct quality and size, significantly reducing the risk of structural failures.

When you use mesh for sizing, you get a product that works well in concrete and asphalt. You also keep out dirt and other things that can weaken your mix.

Material screening aids in sorting out undesirable particles, leading to a consistent product that is vital for concrete’s workability, strength, and durability.

You can use different screens for different jobs. Some screens have bigger holes for large gravel. Others have smaller holes for fine sand. You pick the right mesh for your needs.

Dewatering Washed Materials

After you wash your sand or gravel, you need to get rid of the extra water. Dewatering screens help you do this job fast. You feed the wet material onto the screen. The screen sits at an angle and vibrates. Water drains through the mesh, leaving you with drier aggregate.

Dewatering screens work well for sand, gravel, coal, and even minerals. You can use them for many types of washed materials. The screen uses a special motion to move the material up a slope. Water forms a pool at the bottom, and the mesh lets water and tiny bits pass through. The rest of the aggregate moves up and out, ready for use.

You get a cleaner, drier product. This helps you save on drying costs and makes your material easier to handle. You also keep your work area safer because you do not have puddles or mud.

River Pebble Separation

River pebbles come in all shapes and sizes. You need to sort them before you use them in landscaping or construction. Gravel screen mesh makes this easy. You pour the pebbles onto the screen. The mesh lets small stones fall through and keeps the bigger ones on top.

You can use several screens in a row to get different sizes. This way, you get the perfect pebble for each job. Screening also helps you remove dirt and leaves from your river gravel. You end up with clean, sorted pebbles that look great and work well in your project.

If you want to speed up your work, use vibrating screens. These screens shake the pebbles and help them move across the mesh. You get faster separation and less clogging. Your river pebble jobs become easier and more efficient.

Recycled Aggregate Screening

You may ask how old concrete or asphalt can be reused. Recycled aggregate screening turns waste into useful material. You put mixed debris into a mobile screener. The machine uses vibrating screens to sort by size. First, you load the material onto the screen. The mesh lets small pieces fall through. Bigger chunks stay on top for more sorting.

Here’s how recycled aggregate screening works:

- Mobile screeners sort materials by size.

- You feed mixed debris into the machine. It moves over vibrating screens with different mesh sizes.

- Small particles drop through the mesh. Bigger pieces keep moving forward.

- The machine makes piles based on size and mesh.

This way, you get clean gravel and sand from old construction waste. You can use these recycled materials for new roads or landscaping. Screening keeps recycled aggregate ready for use. You also help the environment by cutting down landfill waste and saving resources.

Tip: Always check your screens for damage. Worn mesh can let big pieces through. This lowers the quality of your recycled aggregate.

Soil & Rock Separation

On construction sites, you often need to separate soil from rocks. Gravel screen mesh makes this job easier. First, you load stone material into a crusher. The crusher breaks big rocks into smaller ones. After crushing, you send the material over vibrating screens. The mesh sorts out different sizes.

Here’s how soil and rock separation works:

- Load stone into the crusher for steady feeding.

- Crush the stone to make smaller pieces.

- Move the crushed material over vibrating screens. The mesh separates small bits from bigger ones.

- Use conveyors to move the sorted material to the right place.

You can use shaker screens to separate soil and debris from drilling fluids. This keeps your worksite cleaner and safer. Strong steel wire mesh lasts longer and handles tough jobs. You can pick different mesh sizes for the separation you need. This keeps your aggregate clean and ready for any project.

Note: Using the right screen and mesh size helps you avoid slowdowns and keeps your screening process smooth.

Benefits of Aggregate Screening Media

Higher Efficiency

You want your screening system to work fast and give you the best results. When you use the right aggregate screening media, you boost your screening efficiency. The media helps you move more material in less time. You get clean, sorted gravel or sand without extra steps. This means you can handle bigger jobs and meet tight deadlines.

With high-quality media, your screen does not clog as much. You spend less time stopping to fix problems. You also get more usable material from each batch. This makes your whole operation smoother and more productive. If you want to save time and money, focus on using the best media for your screening system.

Reduced Blinding

Blinding happens when small particles block the holes in your screen. This slows down your screening and lowers your output. You can avoid this problem with advanced aggregate screening media. Some media, like the Veno Screen, use a smart design with both straight and crimped wires. These wires vibrate at different speeds. The straight wire carries the load, while the crimped wire moves freely. This mix of wires shakes loose any stuck material and keeps the holes open.

When you use this kind of media, you see less blinding and plugging. Fine materials pass through the screen more easily. You do not have to stop your screening system as often to clean the mesh. This keeps your screening running longer and gives you better results. You get more out of every run and waste less time on maintenance.

Tip: Choose media that fights blinding if you work with sticky or wet materials. This keeps your screening system working at its best.

Wear Resistance

You need your aggregate screening media to last a long time, even with tough jobs. Strong media stands up to sharp rocks and heavy loads. This means you do not have to change your screens as often. You save money and keep your screening system running.

Here’s a look at how different media materials compare for wear resistance:

| Feature | Description |

|---|---|

| Material | 65mn Steel |

| Wear Resistance | High wear-resistant properties |

| Application | Quarry Vibrating Screen |

| Customization | Available |

| Warranty | 1 year |

| Material | Middle Carbon Steel |

| Wear Resistance | Abrasion resistant, wear proof |

| Application | Mining, quarry, sieving, grading |

When you pick media with high wear resistance, you get more life out of your screen. You also cut down on downtime and repairs. This keeps your screening system working hard for you, day after day.

Stable Grading

You want your materials to stay consistent from start to finish. Stable grading means you get the same size and quality every time you run your screen. When you use the right aggregate screening media, you control the mix of particles in your gravel or sand. This helps you avoid surprises on the job site.

Here’s how stable grading helps you:

- You get stronger and more reliable construction materials. Properly graded aggregate makes your concrete and asphalt last longer.

- Stable grading fills gaps between particles. This means fewer empty spaces and better strength for your finished product.

- You see less segregation when you move or place your materials. Everything compacts evenly, so your work stays predictable.

Your media keeps the grading steady by sorting out the right sizes during screening. You can trust your screen to deliver the same results, batch after batch. This makes your projects easier to plan and finish.

Less Downtime

Nobody likes to stop work for repairs or cleaning. Less downtime means you spend more time screening and less time fixing problems. When you choose tough aggregate screening media, your screen lasts longer and handles heavy loads without breaking.

Here’s what you gain with less downtime:

- You keep your screening system running smoothly. Strong media resists wear and damage, so you don’t have to change screens as often.

- You avoid clogs and blinding. Smart media design lets material pass through easily, so you don’t waste time clearing blocked holes.

- You save money on repairs and replacement parts. Your screen works harder and longer, so you get more value from your equipment.

If you want to boost efficiency, pick media that stands up to tough jobs. You’ll see fewer delays and more finished product at the end of the day.

Tip: Regular checks and quick swaps keep your media in top shape. You stay ahead of problems and keep your screening line moving.

Consistent Product Quality

You need your final product to meet strict standards every time. Consistent product quality starts with the right media and a reliable screen. When you use high-frequency screens and advanced aggregate screening media, you get better screening efficiency and steady results.

Why does consistent quality matter?

- You deliver uniform materials for road building, concrete, and landscaping. Your customers trust your product because it meets their needs.

- Your screen separates large rocks from fine sand, so every batch looks and performs the same.

- You control the particle size distribution. This means your materials work well in every application, from highways to playgrounds.

- You use media that keeps screening precise. Vibrating screens and smart mesh choices help you avoid mix-ups and keep your quality high.

Your media does more than just sort rocks. It protects your reputation and keeps your business growing. When you focus on consistent quality, you stand out in the market and win more jobs.

Key Screening Functions

Grading & Sizing

You want your finished product to look and perform the same every time. That’s where grading and sizing come in. When you use a screen, you can sort sand, gravel, and other materials by size. This helps you get a well-graded mix for your project. You can trust your screening system to separate out the right pieces, so you don’t have to worry about uneven results.

Here’s a quick look at how grading and sizing work in different places:

| Function | Application |

|---|---|

| Sand & Gravel Processing | Creates well-graded finished products |

| Recycling Operations | Separates finer materials for repurposing |

| Aggregate Plants | Ensures uniform sizing in finished materials |

You can see that a screen helps you get the right size for every job. This means your concrete, road base, or landscaping stones will always meet your needs.

Scalping Large Material

Sometimes, you need to get rid of big rocks before you crush or wash your material. Scalping screens help you do this fast. These screens use a grizzly deck and sometimes a wire mesh deck. When you feed material onto the screen, the vibrating motors shake everything. Fine material falls through the gaps, while large pieces move forward.

You use scalping in many places:

- High capacity and versatile heavy duty screener

- Used in primary and secondary screening applications

- Works in quarry and mining, iron ore, construction demolition waste, sand, gravel, compost, top soil, and coal

Scalping keeps your crusher safe from oversized rocks. You also save time because you don’t have to stop for repairs as often. Your screening operations run smoother, and you get more usable material.

Dewatering Aggregates

After you wash your sand or gravel, you need to get rid of extra water. Dewatering screens help you do this job quickly. You pour wet material onto the screen. The screen sits at an angle and vibrates. Water drains through the mesh, leaving you with drier aggregate.

Dewatering makes your material easier to handle. You don’t have to wait for it to dry. You also keep your work area safer because you avoid puddles and mud. When you use the right screen, you get clean, dry material ready for the next step.

Tip: Check your screens often to make sure they drain water well. Clean screens work faster and last longer.

You can see how each screening function helps you get the best results. Grading and sizing give you the right mix. Scalping protects your equipment. Dewatering keeps your material clean and easy to use.

Choosing Aggregate Screening Media

Aperture Size

When you choose aggregate screening media, think about aperture size first. Aperture size is the size of the holes in your screen. This choice changes how much material you can move and how well you sort it. Small apertures give you more accurate sorting, but you move less material at a time. Big apertures let you move more, but you might not sort as well.

Here are some things to think about when picking aperture size:

- The kind of material you want to separate. Heavy or rough materials like gravel need strong media.

- The size and weight of your material. Bigger rocks need bigger holes.

- How fast you feed material onto the screen.

- If your material is wet, small holes can get clogged.

- The job you want to do, like grading or dewatering.

For example, an 8×20 inch screen with 2mm holes can handle about 100 tonnes per hour. If you use 100mm holes, the same screen can move up to 1000 tonnes per hour. You need to match your mesh size to your project for the best results.

Tip: Always check the rock type and crusher inlet size before you pick your media. This helps you avoid problems during screening.

Wire Diameter & Open Area

Wire diameter and open area are important for how your media works. If you use thinner wire, you get more open space. This means more material can pass through your screen, and your screen still lasts a long time. Open area is the percent of clear space in your screen compared to the whole screen. A higher open area lets you move more material and makes screening faster.

You should compare open area percentages when you look at different media. This helps you see which one will give you better flow and less clogging. If you want to move more material, pick media with a higher open area, but make sure it is still strong.

Material Type

You have a few choices for the shape and type of your screen mesh. Each one has good points and bad points. Here’s a simple table to help you decide:

| Screen mesh shape | Advantages | Disadvantages |

|---|---|---|

| Square | High control accuracy of material particles | Screen holes can block easily, especially under 8mm mesh |

| Rectangular | Increases efficiency, reduces plugging | Only works if particle size is not critical |

| Triangular | Not easy to plug, high screening efficiency | Needs correct conversion to replace square mesh |

Pick the mesh shape that matches your material and your job. If you want high accuracy, use square mesh. If you want less plugging, try triangular mesh. Always match your mesh to your screening needs for the best results.

Note: The right media helps you get clean, sorted material and keeps your screen working longer.

Deck Location

When you set up your screening system, you need to think about where each screen sits on the deck. Deck location matters more than you might think. The spot where you place your screen affects how well it sorts your material. If you get this right, you boost your efficiency and get better results.

You want to pay attention to bed depth. This is the layer of material sitting on top of your screen. Try to keep the bed depth no more than four times the size of the holes in your screen mesh. If the bed gets too deep, smaller pieces can’t reach the openings. They just ride along the top and never fall through. On the other hand, if you have too little material, it can bounce around and miss the holes. That means you lose efficiency and waste time.

Here are some things to keep in mind about deck location:

- Bed depth should not be more than four times the aperture size.

- Too much material on the screen stops small pieces from passing through.

- Too little material causes bouncing and lowers your screening efficiency.

- Different screens have different open areas, so pick the right one for your deck’s position.

- Plain square wire mesh works well on top decks in dry conditions, but it can blind easily if things get wet.

You can use several decks in your screening system. The top deck usually handles the biggest rocks. Lower decks sort out smaller sizes. Each deck needs the right screen mesh sizes to do its job well. If you match the mesh to the deck location, you get cleaner, better-graded material.

Moisture & Stickiness

Moisture and stickiness can turn screening into a real challenge. Wet or sticky material likes to clump together. When this happens, your screen can clog up fast. You might see blinding, where fine particles stick and block the holes. Once this starts, your screen stops working as it should.

You need to watch out for clay and other sticky stuff in your material. These can make your screen useless if you don’t handle them right. Here’s what you should know:

- Wet, sticky materials often clog and blind standard screens.

- Clay content makes screening tough and lowers your output.

- Water spray systems can help wash material and keep the screen clear.

- Trommel screens work better for sticky materials because they tumble and break up clumps.

- Blinding happens when fine particles stick together and block the openings.

If you deal with a lot of moisture, you might need special screens or extra equipment. Sometimes, a trommel screen is the best choice. Its tumbling action helps break up sticky clumps and keeps your material moving. You can also use water sprays to wash away fines and keep the screen open.

Always check your screen for signs of blinding or clogging. If you see problems, try changing your screen mesh sizes or add a spray system. This keeps your operation running smoothly, even when things get wet and sticky.

Common Screening Problems & Solutions

When you run screening operations, you want everything to go smoothly. Sometimes, though, you run into problems that slow you down or mess with your results. Let’s look at the most common issues you might face and how you can fix them.

Blinding & Pegging

Blinding happens when fine or sticky particles clog the holes in your mesh. You might notice your screen stops letting material through. This can lead to low efficiency, production delays, and even damage to your screen. Pegging is similar, but it’s when larger pieces get stuck in the holes.

You often see these problems when you work with wet or sticky materials. Fine particles or high moisture make things worse. When blinding or pegging happens, your material doesn’t get sorted right. You end up with poor sizing and more waste.

Here are some ways you can fight blinding and pegging:

- Use ball trays under your screen. The balls bounce and knock loose any stuck material.

- Try heated screen decks. Heat helps dry out the material and keeps it from sticking.

- Adjust the stroke and speed of your screen. Faster movement can shake loose stubborn particles.

- Change the shape of your mesh holes. Sometimes, a different shape stops pieces from getting stuck.

- Pick more flexible surface media, like rubber or synthetic screens. These can bend and help dislodge particles.

- Minimize blank areas on your screen. Less blank space means fewer spots for sticky stuff to build up.

- Use thinner media if possible. Thinner screens can flex more and shake off clogs.

Tip: If you work with sticky or wet material, check your screens often. Quick fixes keep your operations running strong.

Wear & Breakage

Screens take a beating every day. Sharp rocks and heavy loads can wear down your mesh or even break it. When this happens, you might see holes, tears, or broken wires. Damaged screens let oversized material through and can mess up your whole process.

To keep your screens in good shape:

- Choose wear-resistant materials for your mesh, like 65mn steel or abrasion-resistant alloys.

- Inspect your screens regularly for signs of wear or damage.

- Replace worn or broken screens right away to avoid bigger problems.

- Rotate your screens if possible. This spreads out the wear and helps them last longer.

A strong screen means fewer breakdowns and smoother operations. You save time and money when you stay ahead of wear and tear.

Loose Tension

Loose tension is another problem you might face. If your screen mesh isn’t tight, it can sag or move too much. This makes your screening less effective. You might see poor separation, more blinding, or even extra wear on your mesh.

Here’s what you can do:

- Check the tension of your screens often. Tighten them as needed.

- Use the right tensioning tools for your mesh type.

- Make sure your screen is installed correctly. A good fit keeps everything working as it should.

Note: Tight screens give you better results and help your equipment last longer.

When you watch for these common problems and fix them fast, your screening operations stay efficient. You get better material, less downtime, and a smoother workflow every day.

Conclusion

You use mesh every day in mining and aggregate work. Mesh helps you sort gravel, keep your products clean, and boost your results. When you pick the right screen mesh sizes, you get proper screening and less downtime. Take care of your mesh and choose custom options for size, aperture, or material. If you need help, reach out to a manufacturer for expert advice and support.

FAQ

What is gravel screen mesh made of?

You usually find gravel screen mesh made from high-tensile steel, stainless steel, or polyurethane. These materials help the mesh last longer and handle tough jobs. You can pick the right type based on your project and the material you need to screen.

How do I choose the right mesh size?

Start by looking at the size of the material you want to separate. Smaller holes catch fine sand, while bigger holes work for large rocks. If you want the best results, match your mesh size to your job needs.

How often should I replace my screen mesh?

You should check your mesh regularly for wear or damage. If you see holes, tears, or broken wires, it’s time for replacement aggregate screening media. Regular checks help you avoid downtime and keep your screening line running smoothly.

Can I use the same mesh for wet and dry materials?

You can use some mesh types for both wet and dry materials, but sticky or wet materials may need special screens. If you work with a lot of moisture, try screens that resist blinding or clogging.

What are the best screening machines for gravel?

The best screening machines for gravel use strong vibration and have adjustable decks. Look for machines that let you change mesh sizes easily. This way, you can handle different materials and get clean, sorted products every time.

Why does my screen keep clogging?

Clogging happens when fine or sticky particles block the holes. Try using a mesh with a special shape or add a spray system to wash away the clumps. Regular cleaning and the right mesh size help prevent this problem.

Can I customize my gravel screen mesh?

Absolutely — you can customize your gravel screen mesh.

As a manufacturer, we produce gravel screen mesh to your exact requirements, including panel dimensions, aperture size and hole pattern (square or slot), wire diameter, material (high-carbon steel or stainless steel), weave style, and edge finishing/connection methods. This ensures a perfect fit for your vibrating screen and better performance on your specific material.