You might look at a pile of gravel and wonder if there’s any real difference between limestone screenings vs crushed stone. These two materials may look similar, but they can make or break your project. Particle size, compaction, and drainage all play a big role. If you pick the wrong one, you could face more repairs, higher costs, or poor results. Knowing what sets them apart helps you get a durable, low-maintenance finish for your space.

Key Takeaways

- Limestone screenings are tiny pieces that make a smooth, packed surface. They work well for patios and walkways.

- Crushed stone has bigger, rough pieces. It is strong and lets water drain well. This makes it good for driveways and roads.

- Pick limestone screenings if you need a flat base. But remember, water does not drain fast through them.

- Use crushed stone if you need water to drain quickly. The bigger spaces let water move away fast.

- Think about how heavy and busy your project will be. Crushed stone can hold more weight than limestone screenings.

- Always check if the materials are easy to get and how much they cost. This helps you avoid waiting and surprise expenses.

- Plan for upkeep. Limestone screenings may need more added in low spots. Crushed stone lasts longer when used a lot.

- Use a checklist to pick the best material for your project. Think about things like water, traffic, and how much care it needs.

What Are Limestone Screenings?

Limestone screenings might sound fancy, but you probably know them by other names like stone dust or FA5. When you compare limestone screenings vs crushed stone, you’ll notice that screenings have a much finer texture. You get these tiny particles as a by-product when big chunks of limestone go through crushing and screening machines.

Physical Properties

Limestone screenings look almost like coarse sand. The particles are very small, usually less than a quarter inch across. If you pick up a handful, you’ll see it feels powdery and soft. This fine texture helps the material pack down tightly. When you add water and compact it, the screenings lock together and form a solid surface. You’ll find that this makes them great for projects where you want a smooth, flat base.

Screenings are also lighter in color compared to other aggregates. They often appear pale gray or off-white. Because of their size, they don’t drain water as quickly as larger stones. This can be a good thing or a bad thing, depending on your project.

How Screenings Are Made

You might wonder how limestone screenings end up in your yard or driveway. The process starts with picking out the right limestone from a quarry. Workers use heavy machines to crush the rock into smaller pieces. After that, the crushed stone goes through screens that separate the fine particles from the bigger chunks. The fine stuff that falls through the screens becomes limestone screenings.

Here’s a quick look at the steps:

- Workers extract limestone from the ground.

- Machines crush the rock into smaller pieces.

- The crushed material passes through screens.

- Fine particles that pass through become screenings.

This process uses careful equipment choices and planning to make sure everything runs smoothly. The result is a steady supply of fine, compactable material for your projects.

Common Uses

You’ll see limestone screenings used in lots of landscaping and construction jobs. Their fine texture and ability to pack down make them a popular choice.

Walkways and Patios

If you want a sturdy base for your patio or garden path, limestone screenings work well. You can spread them out, wet them, and compact them to create a flat, stable surface. This makes it easier to lay pavers or stones on top. The screenings fill in gaps and help prevent shifting over time.

Driveways and Paths

Many people use limestone screenings for driveways and simple paths. The material compacts well, so you get a smooth surface that’s easy to walk or drive on. It’s also more affordable than some other options, which helps if you’re working with a tight budget.

You might also see screenings used for soil amendment, drainage, or even erosion control in landscaping. They’re a versatile choice for many outdoor projects.

Tip: If you’re deciding between limestone screenings vs crushed stone, think about drainage and compaction. Screenings give you a smooth, tight base, but they don’t drain as well as larger stones.

What Is Crushed Stone?

Crushed stone is a popular building material that you see almost everywhere. You might spot it under roads, driveways, or even around your home. When you compare limestone screenings vs crushed stone, you’ll notice that crushed stone comes in bigger, chunkier pieces. These stones are made by breaking down large rocks into smaller, angular bits. The size and shape of the pieces can change depending on what you need for your project.

Physical Properties

Crushed stone has a rough, angular shape. This helps the pieces lock together when you spread them out. The stones come in different sizes, from big chunks to smaller gravel. Each type has its own job. For example, you might use larger stones for a road base and smaller ones for drainage.

Here’s a table that shows some common physical properties of crushed stone:

| Property | Type 1 (20 mm max) | Type 2 (15 mm max) | Type 3 (10 mm max) | Type 4 (5 mm max) |

|---|---|---|---|---|

| Relative Density – SSD | 2.68 | 2.67 | 2.68 | 2.68 |

| Relative Density – Dry | 2.67 | 2.65 | 2.65 | 2.62 |

| Apparent Specific Gravity | 2.70 | 2.71 | 2.73 | 2.80 |

| Water Absorption (% of dry mass) | 0.65 | 1.00 | 1.01 | 1.20 |

| Los Angeles Abrasion Value (%) | 23.5 | 24.0 | 25.0 | 26.0 |

| Particle Shape | Angular | Angular | Angular | Cubical |

| Surface Texture | Rough | Rough | Rough | Smooth |

You can see that crushed stone is dense and strong. The rough texture helps it stay in place, even under heavy loads.

Production Process

You might wonder how crushed stone is made. The process uses big machines and several steps to get the right size and shape. Here’s how it works:

- Workers mine large pieces of limestone from the ground.

- A jaw crusher breaks the rocks into smaller stones, about 10-30 cm wide.

- A cone crusher crushes them again, making pieces 3-10 cm wide.

- An impact crusher makes the stones even smaller, down to 0-5 mm.

- Vibrating screens sort the stones by size, so you get the right type for your project.

This process gives you a range of stone sizes, each with its own use.

Typical Applications

Crushed stone is a go-to choice for many outdoor projects. You’ll see it used in places that need strength and good drainage.

Driveway and Road Base

If you want a driveway that can handle cars and trucks, crushed stone is a smart pick. The angular stones lock together, making a strong base that won’t shift. Road builders use it under highways and streets for the same reason. The stone spreads out weight and keeps the surface stable.

Drainage Layers

Crushed stone works great for drainage. Builders use #57 stone, a common size, to help water flow away from buildings and roads. The gaps between the stones let water pass through, which stops puddles and flooding. You might see this stone around foundations or under patios to keep things dry.

Note: Crushed stone goes by different names in different places. Always check the size and type before you buy, so you get the right material for your job.

When you look at limestone screenings vs crushed stone, remember that crushed stone is best for heavy loads and places where water needs to drain away fast.

Limestone Screenings vs Crushed Stone

When you plan an outdoor project, you might wonder about limestone screenings and crushed stone. Both come from limestone, but they act differently when used. Let’s look at what makes them different so you can choose the right one.

Key Differences

Size and Gradation

The first thing you notice is the size of the pieces. Limestone screenings have tiny particles, almost like powder. Crushed stone has bigger, chunkier pieces. The mix of sizes changes how each one packs down and drains water.

Here’s a quick look at how they compare:

| Material | Particle Size | Gradation |

|---|---|---|

| Limestone Screenings | ≤6mm | Fine particles, compacts tightly, creates a smooth, dense surface |

| Crushed Stone | 1/4″ (~6mm) | Extremely fine to chunky, angular particles, dense and stable after paving |

Limestone screenings make a smoother surface. Crushed stone gives a rougher, more bumpy finish.

Compaction

Both materials can make a solid base, but they pack down in different ways. Limestone screenings pack tightly and make a hard, flat layer. You can use them under pavers or walkways for a strong base. Crushed stone also packs well, but the bigger pieces leave small spaces. These spaces help water drain, but the surface is not as smooth.

- Limestone screenings make a base that does not move much.

- Crushed stone mixes gravel and sand, making it tough.

Drainage

Drainage is important when picking between limestone screenings and crushed stone. Limestone lets water pass through because it is porous. This is good for gardens and paths. But the fine particles in screenings can slow water down, especially in wet places. Crushed stone has bigger gaps, so water moves away fast. That’s why people use it for driveways, roads, and drainage layers.

Tip: If you want to stop puddles or flooding, crushed stone is better for drainage.

Cost

Cost is important for any project. Limestone screenings usually cost less because they are easy to get. Crushed stone can cost more, especially if you live far from where it is made. Both are a good deal, but check prices near you before you pick.

- Crushed stone is known for being strong and not too expensive.

- Limestone screenings are cheap and easy to find.

Comparison Table

Let’s put these features side by side so you can see the differences quickly:

| Feature | Limestone Screenings | Crushed Stone |

|---|---|---|

| Formation | Crushed and screened limestone rocks | Crushed and screened limestone rocks |

| Shape | Angular, rough, sharp edges | Angular, rough, sharp edges |

| Composition | Calcium carbonate (CaCO₃) | Calcium carbonate (CaCO₃) |

| Particle Size | ≤6mm, powdery | 1/4″ (~6mm), chunky |

| Gradation | Fine, smooth, dense | Mixed, angular, stable |

| Compaction | Packs tightly, forms hard surface | Locks together, leaves gaps for drainage |

| Permeability | High, but slows with fine particles | High, drains quickly due to gaps |

| Primary Applications | Paver base, walkways, soil amendment | Driveways, road base, drainage layers |

| Cost | Cost-effective, widely available | Affordable, may vary by location |

| Maintenance | Durable, long-lasting, needs topping in low spots | Minimal ongoing costs, may need replenishment |

| Longevity | Stable base, minimizes shifting | Withstands heavy use, durable |

If you want a flat, packed base for pavers or paths, limestone screenings are a good pick. If you need good drainage or a surface for heavy loads, use crushed stone. Both are useful, so think about what your project needs before you choose.

Remember: Clear leaves off both surfaces to help drainage. Rake stones back into place, and add more screenings to low spots each spring.

By knowing the differences between limestone screenings and crushed stone, you can pick the best one and avoid problems later.

Best Uses and Limitations

Picking between limestone screenings and crushed stone can be hard. But knowing what each one does best makes it easier. Let’s look at when to use each material and when to avoid them.

When to Use Limestone Screenings

Limestone screenings are great for smooth, packed surfaces. They work well in these cases:

Paver Base

If you want a flat base for patio pavers, use limestone screenings. They pack tight and keep pavers from moving. But they do not drain water as well as sand. So, use them in dry places.

Walkways

Building a garden path or walkway? Screenings make the surface smooth. They fill gaps and make walking easy.

Filling and Patching

Screenings help fill small holes or patch low spots. Their fine texture makes spreading and packing simple.

Limestone screenings are also used in big jobs. For example:

- A Michigan mining company uses screenings for loading ships. They move up to 4,000 short tons per hour with special machines.

When to Use Crushed Stone

Crushed stone is best for strength and drainage. Here’s where it works well:

Driveways

If you need a driveway for cars or trucks, use crushed stone. The stones lock together and make a tough surface.

Drainage

Want to move water away from your home or garden? Crushed stone is good for that. Water flows through the gaps, so it works for French drains or near foundations.

Heavy-Load Bases

Building a shed, wall, or road? Crushed stone makes a strong base that holds heavy things.

Civil engineers also use crushed stone for:

- Building foundations, walls, and floors

- Landscaping like garden beds and retaining walls

- Drainage systems and French drains

When Not to Use Each Material

Some projects are not right for limestone screenings or crushed stone. Here are times to avoid them:

- Small vehicles like bikes or wheelchairs can have trouble on regular gravel. Use finer gravel, limestone fines, or crushed limestone sand for smoother travel. Or pick ¼” minus gravel for less bumps.

- For wheelchair paths, use the smallest gravel you can.

Screenings can hold water instead of letting it drain. This happens under pavers and can cause shifting or cracks when it freezes. Concrete sand is better for paver bases in wet places.

Crushed stone can also be bad in wet spots:

- Water can soak the ground and make the stone sink. This causes ruts or potholes.

- Erosion can happen if water runs down the driveway. It washes away the fines and hurts the surface.

- Standing water makes muddy, weak surfaces and can cause problems.

When you compare limestone screenings and crushed stone, match the material to your project. Think about drainage, weight, and who will use it. This helps you get good results and avoid mistakes.

Choosing the Right Material

Picking the right aggregate can feel overwhelming, but you can make it simple by following a checklist. Let’s break it down so you get the best results for your project.

Selection Checklist

Project Type

Start by thinking about what you want to build. Are you working on a driveway, a patio, or a walking path? Each project needs a different type of base. For a driveway that handles passenger cars, you’ll want ¾″ minus crushed limestone. If you need a heavy-duty driveway or a farm lane, go for a larger base like 1½″ minus or pit-run rock. For a walking path or patio, ¼″ minus limestone screenings give you a firm, level surface.

Moisture and Drainage

Next, look at how much water your project area gets. If you have a spot that stays wet or gets lots of rain, drainage matters. Crushed stone with larger particles lets water move away fast, which helps prevent puddles and flooding. If you need a stable surface but don’t want water to pool, pick an aggregate with bigger pieces. Smaller particles, like screenings, fill gaps and make things stable, but they can slow down drainage.

Tip: If you’re building in a wet area, crushed stone is usually the better choice for drainage.

Traffic Load

Think about how much weight your surface will hold. Will you drive cars or trucks over it? Heavy traffic needs a strong base. Crushed stone works well for driveways and roads because the angular pieces lock together and support heavy loads. For light foot traffic, like garden paths or patios, limestone screenings are enough.

Maintenance Needs

Ask yourself how much time you want to spend on upkeep. Some materials need more topping up or raking. If you want less maintenance, choose a material that fits your project’s needs from the start. For example, crushed stone holds up well under heavy use, while screenings may need to be topped off in low spots.

Common Mistakes

You can avoid headaches by steering clear of these common mistakes:

- Relying only on price and picking the cheapest material. This can lead to weak surfaces and more repairs.

- Ignoring what’s available locally. If you choose something hard to find, you might face delays and higher delivery costs.

- Forgetting about the environment. Some materials have a bigger impact, so think about sustainability.

- Not checking your supplier’s reputation. Poor-quality materials or late deliveries can ruin your schedule.

- Overlooking future maintenance. If you don’t plan for upkeep, you could end up spending more over time.

When you compare limestone screenings vs crushed stone, use this checklist to match the right material to your project. You’ll save time, money, and effort—and get a result that lasts.

Technical Note on Aggregate Screening

Screening Process

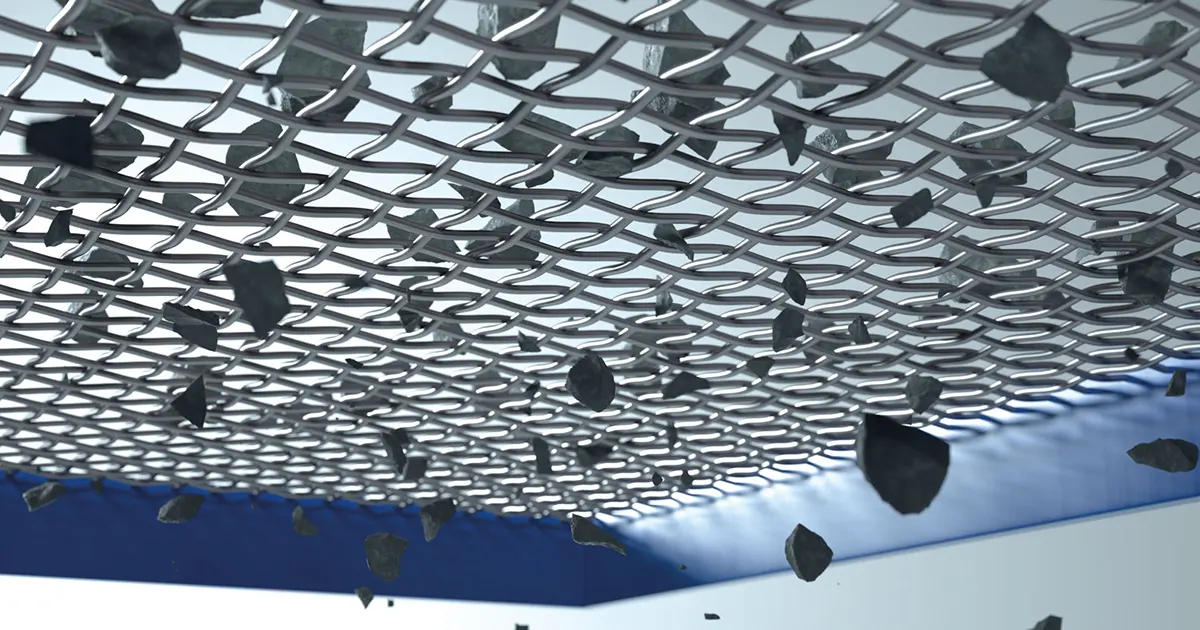

You might wonder how limestone screenings and crushed stone get sorted into different sizes. The process uses big machines and smart steps to make sure you get the right material for your project. Here’s how it works:

- Crushing: Workers break down large limestone rocks into smaller pieces.

- Screening: Vibrating screens sort the crushed rock by size. Smaller particles fall through the screen openings, while bigger pieces stay on top.

- Closed-Circuit System: If any pieces are too big, the system sends them back to the crusher. This keeps the process going until everything meets the size you need.

This step-by-step method helps you get consistent gradation. You end up with fine screenings for patios or chunky crushed stone for driveways.

Screen Openings and Gradation

The size of the screen openings matters a lot. If you use a screen with small holes, you get fine particles like limestone screenings. Bigger openings let larger stones pass through, which works well for drainage layers or road bases.

Gradation means the mix of particle sizes in your aggregate. Good gradation gives you a strong, stable base. If the mix is off, your surface might shift or drain poorly. You want the right balance for your project. For example, patios need fine screenings for a smooth finish, while driveways need a mix of sizes for strength and drainage.

Screening media also play a big role. You can choose from woven wire mesh, self-cleaning screens, polyurethane panels, or punch plates. Each type helps control the size and quality of your aggregate. Self-cleaning screens and synthetic media can reduce clogging and keep your operation running smoothly.

Tip: Ask your supplier about the screen media they use. The right choice can improve consistency and cut down on maintenance.

Blinding and Pegging

Sometimes, problems pop up during screening. Blinding happens when sticky fines cover the screen openings. Pegging is when rocks get stuck in the holes. Both issues slow down the process and hurt product quality.

You can spot these problems if you see material piling up on one side of the screen or notice clogging in the openings. These issues make your operation less efficient and can lead to uneven gradation.

Here are some ways to fight blinding and pegging:

- Adjust the aperture size and screen cloth design.

- Use flexible media like rubber or self-cleaning wire cloth.

- Try rubber or synthetic panels that resist buildup.

- Optimize media thickness and open area to help material move better.

If you keep your screens clean and pick the right media, you’ll get better results. Your aggregate will be more consistent, and your project will last longer.

Note: Regular checks and smart media choices help you avoid downtime and keep your aggregate quality high.

Conclusion

You know limestone screenings and crushed stone are good for different jobs. Screenings work well for patios and walkways. They make a smooth and steady base. Crushed stone is better for driveways or places that need drainage. Here’s a simple guide:

| Material | Common Scenarios |

|---|---|

| #132 Screenings | Patios, walkways, driveways, under concrete slabs |

| #57 Stone | Drainage, driveways, foundations, roadways |

When choosing aggregate, talk with your supplier about the right gradation for your project. A good supplier can confirm material quality, recommend the best product for your application, and coordinate delivery.

We are a screening media manufacturer, producing woven wire screen mesh and self-cleaning screens used in aggregate and mining plants. With the right screen openings and media design, you can maintain consistent particle sizing and reduce blinding and clogging for more stable output.

FAQ

What’s the main difference between limestone screenings and crushed stone?

Limestone screenings have tiny, powdery particles. Crushed stone has bigger, chunky pieces. Screenings pack tightly for smooth surfaces. Crushed stone works better for drainage and heavy loads.

Can I use limestone screenings for a driveway?

You can use screenings for light driveways. They make a smooth surface. If you expect heavy cars or trucks, crushed stone gives you more strength and lasts longer.

Do limestone screenings drain water well?

Screenings slow down water because the particles are so fine. If you want fast drainage, pick crushed stone. It has gaps that let water flow through easily.

Which material is best for a paver base?

Limestone screenings work well for paver bases in dry areas. They pack tight and keep pavers steady. In wet spots, use concrete sand or crushed stone for better drainage.

How often do I need to add more aggregate?

You might need to top up screenings every year, especially in low spots. Crushed stone holds up longer but may need raking or extra stones after heavy use.

Can I mix limestone screenings and crushed stone?

You can mix them for some projects. Screenings fill gaps and make things smooth. Crushed stone adds strength and helps with drainage. Ask your supplier for the best blend.