When you compare flip flow screens vs banana screens for fine coal screening, you’ll notice that flip flow screens come out on top for efficiency. These screens handle fine and sticky coal much better, especially as raw coal input increases. Banana screens move more material, but flip flow screens actually process more fine coal under the same conditions. Screening fine coal isn’t easy. You have to deal with tighter specs, blinding, pegging, and wet coal that clumps together and slows things down.

Key Takeaways

- Flip flow screens work well with fine, sticky, and wet coal. They separate coal better and need less downtime.

- Banana screens are best for big jobs with dry coal. They can process lots of coal quickly.

- Pick flip flow screens if you want good separation. They also help you clean and fix less often.

- Banana screens do not work well with sticky coal. This can cause more blockages and cleaning.

- Think about how wet your coal is before you choose a screen. Flip flow screens do better with wet coal.

- Flip flow screens clean themselves, so you spend less time on maintenance than with banana screens.

- Look at your production needs. If you need speed, banana screens are good for moving lots of coal.

- Flip flow screens cost more at first. But they can save you money on maintenance over time.

Screen Types Overview

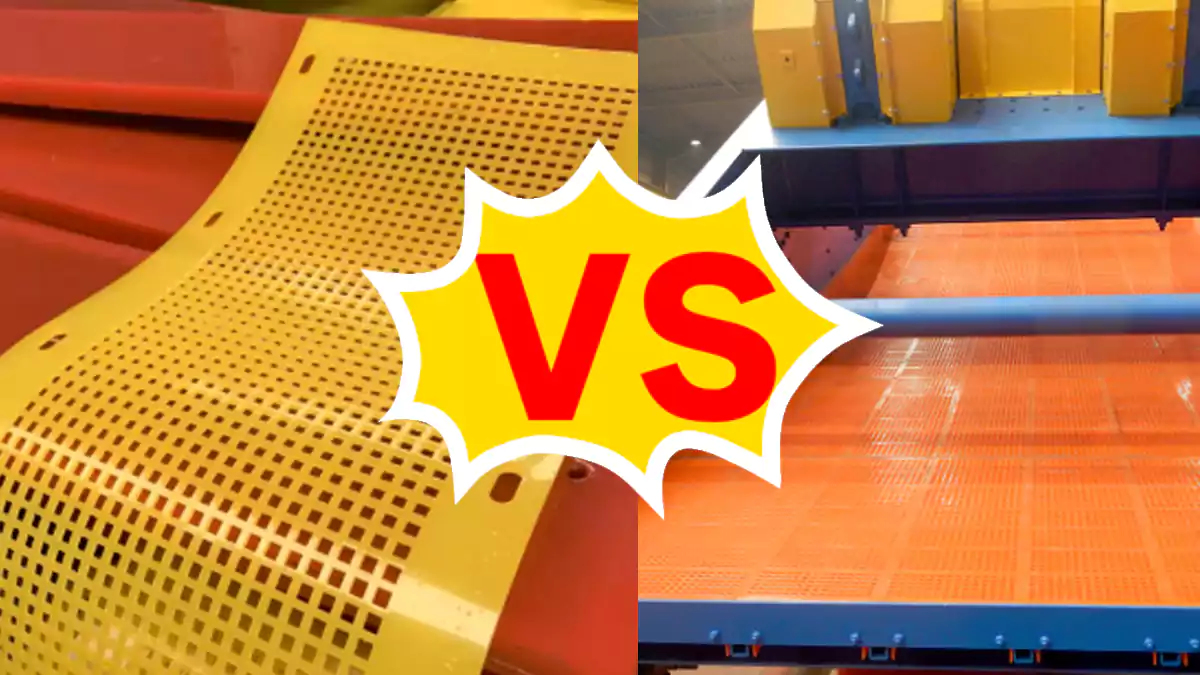

Flip Flow Screens

Working Principle

You might wonder how flip flow screens actually work. These screens use a flexible and elastic screen surface that stretches and rebounds quickly. A vibration motor powers this movement, making the screen surface flip and flow in a unique way. This action helps shake loose even the smallest coal particles.

- The screen surface is made from wear-resistant polyurethane, which lasts longer and handles tough materials.

- The system uses a two-body vibration setup. There’s a main frame and a floating frame. This design helps the screen move in two different ways at once.

- An elastic support device, like rubber or coil springs, absorbs the shock and keeps the machine steady.

- The transmission system lets you control how fast and how much the screen moves.

- The whole screen box stays closed, so you don’t have to worry about coal dust escaping.

Tip: The alternating stretching and relaxing of the screen surface creates strong vibrations. This helps separate fine coal particles and keeps the screen from clogging.

Handling Sticky Materials

If you deal with sticky or wet coal, flip flow screens make your job easier. The elastic polyurethane screen plates flex and snap back, which shakes off sticky particles. This means you spend less time cleaning and more time screening.

- The flip flow motion keeps the screen surface clean, even when coal is wet or clumpy.

- The high acceleration from the screen’s movement helps break up sticky lumps.

- You get better stratification, so fine particles move to the bottom and pass through the screen.

Banana Screens

Working Principle

Banana screens look a bit different. They use an arc-shaped, multi-slope design. This shape helps coal move faster across the screen. The screen surface usually has several slopes, starting steep and getting flatter.

| Feature | Description |

|---|---|

| Multi-slope screen | Coal moves quickly at first, then slows down for better sorting. |

| High processing speed | You can handle a lot of material at once. |

| Efficient stratification | Fine coal particles stay close to the screen, making it easier to separate. |

| Modular design | You can swap out parts easily for maintenance. |

Banana screens use different materials for the screen surface. They don’t always use polyurethane like flip flow screens. The support system may also vary, but the main idea is to keep coal moving smoothly.

Flow Rate Control

You can control how fast coal moves across a banana screen by adjusting the slope and the vibration settings. The arc shape helps regulate the speed. At the start, coal moves quickly, which spreads it out. As the slope flattens, the coal slows down, giving fine particles more time to fall through the screen.

- You can adjust the screen to match the type of coal you have.

- The design works best when you need to process a lot of material quickly.

- Banana screens are great for high-volume jobs, but they may struggle with very sticky or wet coal.

When you compare flip flow screens vs banana screens, you’ll see that each has a unique way of moving and sorting coal. Flip flow screens focus on handling fine and sticky materials, while banana screens shine in high-capacity operations.

Flip Flow Screens vs Banana Screens: Performance

Screening Efficiency

Fine Particle Handling

You want to catch as much fine coal as possible. Flip flow screens vs banana screens show big differences here. Flip flow screens grab tiny particles with their elastic surfaces. The screen stretches and snaps back, shaking loose even the smallest bits. You get less blinding and more accurate separation.

Banana screens use a sloped design. Fine particles move along the screen, but some slip through gaps or stick to the surface. You might miss some fines, especially if the coal is sticky or damp.

| Screen Type | Fine Particle Capture | Blinding Risk | Accuracy |

|---|---|---|---|

| Flip Flow | High | Low | Excellent |

| Banana | Moderate | Medium | Good |

Note: If you need to screen coal with lots of fines, flip flow screens give you better results.

Wet and Sticky Coal

Wet and sticky coal can slow you down. Flip flow screens vs banana screens handle this challenge in different ways. Flip flow screens use flexible polyurethane surfaces. These surfaces shake off sticky lumps and keep the screen clean. You spend less time clearing blockages.

Banana screens struggle with sticky coal. The material clumps together and blocks the screen. You might need to stop and clean the surface more often.

- Flip flow screens keep working even when coal is wet.

- Banana screens need extra maintenance with sticky material.

Throughput and Capacity

High-Volume Operations

You want to move a lot of coal fast. Banana screens shine in high-volume jobs. The multi-slope design pushes coal across the screen quickly. You can process large amounts in less time.

Flip flow screens handle moderate volumes well. They focus on quality over speed. If you need to screen fine coal, you might sacrifice some throughput for better separation.

| Screen Type | Throughput | Best Use Case |

|---|---|---|

| Flip Flow | Medium | Fine, sticky, wet coal |

| Banana | High | Dry, bulk material |

Tip: Choose banana screens if you need to process huge loads and the coal is not sticky.

Limitations with Fine Coal

Flip flow screens vs banana screens show clear limits with fine coal. Flip flow screens keep working when coal is wet or sticky. They separate fine particles with high accuracy. Banana screens lose efficiency with fine, sticky coal. You might see more blinding and less separation.

- Flip flow screens handle fine coal without clogging.

- Banana screens work best with larger, dry particles.

Separation Quality

You want clean, sorted coal. Flip flow screens vs banana screens offer different levels of separation quality. Flip flow screens use strong vibrations and elastic surfaces. You get sharp separation and fewer misplaced particles. The screen keeps itself clean, so you see less contamination.

Banana screens rely on slope and speed. You get good separation with dry coal, but sticky or fine material can slip through. The screen might need more cleaning to keep quality high.

Alert: If you need top separation quality for fine coal, flip flow screens give you the edge.

Pros and Cons

Flip Flow Screens: Pros

When you look at flip flow screens, you’ll see a bunch of benefits that make your job easier. These screens work well in tight spaces because of their compact design. You don’t need a huge area to set them up, so you save space in your plant. The modular build means you can swap out parts quickly. You spend less time on repairs and more time running your operation.

Here’s a quick look at the main advantages:

| Advantage | Description |

|---|---|

| Compact Design | Reduces machine footprint and increases operational efficiency. |

| Fewer Moving Parts | More modular compared to alternative screening equipment. |

You also get some extra perks:

- Enhanced vibration strength shakes loose even stubborn coal particles.

- Automatic cleaning function keeps the screen surface clear, so you don’t have to stop for cleaning.

- Reduced hard blockage of the mesh means less downtime and fewer headaches.

Flip flow screens handle fine, sticky, and wet coal with ease. You won’t see much blinding or clogging. The elastic polyurethane surface flexes and snaps back, so sticky lumps fall off. You get better separation and cleaner coal. If you need to meet strict specs, flip flow screens help you hit your targets.

Tip: If you want a screen that cleans itself and keeps working, flip flow screens are a smart choice.

Flip Flow Screens: Cons

Even though flip flow screens offer lots of benefits, you should know about a few drawbacks. These screens don’t always handle huge volumes as fast as banana screens. If you need to process massive loads, you might see slower throughput.

You may also notice higher upfront costs. The advanced design and special materials, like polyurethane, can cost more than basic screens. Maintenance is easier, but replacement parts might be pricier.

Flip flow screens need skilled operators. The system uses two-body vibration and elastic supports, so you want someone who understands the setup. If you don’t have trained staff, you could run into problems.

Sometimes, the closed screen box makes it harder to spot issues right away. You need to check the system regularly to catch small problems before they grow.

Banana Screens: Pros

Banana screens shine when you need to move a lot of coal quickly. The multi-slope design pushes material across the screen at high speed. You can handle big loads without slowing down. If your coal is dry and not sticky, banana screens work well.

You get easy access for maintenance. The modular design lets you swap out worn parts fast. You don’t need special skills to run a banana screen. The setup is simple, and most operators can learn it quickly.

Banana screens give you good separation for larger particles. The arc shape spreads out the coal, so fines have a chance to fall through. You can adjust the slope and vibration to match your needs.

Note: If you want high throughput and simple operation, banana screens are a solid pick.

When you compare flip flow screens vs banana screens, you’ll see that each has strengths in different areas. Flip flow screens excel with fine, sticky coal and automatic cleaning. Banana screens win with high-volume, dry material and easy maintenance.

Banana Screens: Cons

Banana screens might look like a great choice for moving lots of coal, but you’ll run into some real challenges if you use them for fine or sticky material. Let’s break down the main drawbacks you should know about before making your decision.

- Struggles with Sticky or Wet Coal

Banana screens don’t handle sticky or wet coal well. The material can clump together and stick to the screen surface. You’ll see more blockages and spend extra time cleaning. If your coal is damp or has a lot of fines, you’ll probably get frustrated with the constant maintenance. - Blinding and Pegging Happen Often

Fine particles can block the screen openings. This is called blinding. When larger pieces get stuck, that’s pegging. Both problems slow down your operation. You’ll need to stop the screen and clear the blockages, which means more downtime. - Lower Efficiency for Fine Coal

Banana screens work best with larger, dry particles. If you try to screen fine coal, you won’t get the same accuracy as you would with a flip flow screen. Some fine particles will pass through with the oversize material, so you lose valuable product. - Frequent Cleaning and Maintenance

You’ll need to clean banana screens more often, especially if you process sticky or wet coal. The screen surface can get clogged, and cleaning takes time away from production. Maintenance is simple, but you’ll do it more often. - Less Precise Separation

If you need sharp separation between different coal sizes, banana screens might disappoint you. The sloped design moves material quickly, but it doesn’t always give fine particles enough time to fall through. You might see more contamination in your final product.

Here’s a quick table to help you see the main cons at a glance:

| Drawback | Impact on Operation |

|---|---|

| Handles sticky coal poorly | More cleaning, more downtime |

| Frequent blinding/pegging | Slower screening, lost efficiency |

| Lower fine coal accuracy | Valuable fines lost, less profit |

| More cleaning needed | Higher labor and maintenance costs |

| Less precise separation | Lower product quality |

Alert: If your plant deals with wet, sticky, or fine coal, banana screens will likely cause more headaches than solutions.

You want a screen that matches your coal and your workflow. Banana screens can move a lot of material, but they don’t always give you the clean, fine product you need. Think about your coal type and your production goals before you choose.

Maintenance and Cost

Maintenance Needs

You want your screening equipment to run smoothly with as little downtime as possible. Flip flow screens and banana screens have different maintenance needs, so you should know what to expect before you choose.

Flip flow screens use elastic polyurethane surfaces. These surfaces clean themselves most of the time, so you spend less time scraping off stuck coal. You might need to check the tension of the screen panels and inspect the vibration system. The two-body vibration setup means you should look at both the main frame and the floating frame. If you spot wear or damage, you can swap out modular parts quickly.

Banana screens need more frequent cleaning, especially if you handle sticky or wet coal. You may see blinding or pegging, which means you have to stop and clear the screen. The modular design helps you replace worn panels, but you might do this more often than with flip flow screens. You should check the vibration motors and make sure the slopes stay in good shape.

Here’s a quick checklist for both screens:

- Flip Flow Screens

- Inspect polyurethane panels for wear

- Check vibration system and supports

- Tighten bolts and fasteners

- Clean dust from the closed box

- Banana Screens

- Remove blinding and pegging

- Replace worn screen panels

- Check slope angles and vibration motors

- Clean open surfaces regularly

Tip: If you want less downtime, flip flow screens usually need less cleaning and fewer repairs.

Cost Factors

You care about your budget. The cost of screening equipment includes more than just the price tag. You should think about installation, maintenance, and how long the screen lasts.

Flip flow screens cost more upfront. The advanced design and polyurethane panels raise the price. You save money on maintenance because the screens clean themselves and parts last longer. You might pay more for replacement panels, but you won’t need them as often.

Banana screens cost less to buy. You spend less at the start, but you may pay more over time. Frequent cleaning and panel replacement add up. If you process sticky or wet coal, you might see higher labor costs.

Here’s a table to help you compare:

| Cost Factor | Flip Flow Screens | Banana Screens |

|---|---|---|

| Initial Purchase | High | Moderate |

| Maintenance | Low | Moderate to High |

| Replacement Parts | Moderate | Moderate |

| Labor Costs | Low | High (sticky coal) |

| Lifespan | Long | Moderate |

Note: If you want to save money in the long run, flip flow screens may cost more at first, but you spend less on cleaning and repairs.

You should look at your coal type and your plant’s needs before you decide. If you process fine, sticky coal, flip flow screens help you cut maintenance and labor costs. If you handle dry, bulk material, banana screens give you a lower starting price.

Choosing the Right Screen

Decision Factors

You want to pick the right screen for your coal plant. The choice depends on a few key things. First, look at the type of coal you handle. If your coal is sticky or has a lot of moisture, you need a screen that can deal with those problems. Flip Flow Screens work best with wet and sticky coal. Their flexible surface shakes off clumps and keeps the screen clean. You get less blockage and more fine coal separated.

Moisture content matters a lot. Wet coal can clog up regular screens and slow down your process. Flip Flow Screens keep working even when the coal is damp. Studies show these screens reach over 85% efficiency with moist coal. You get better results and fewer headaches.

Plant throughput is another big factor. If you need to move huge amounts of coal fast, Banana Screens handle high volumes well. Their sloped design pushes coal across quickly. You can process more material in less time. But if you care more about catching fine particles and keeping the screen clean, Flip Flow Screens give you better separation.

Here’s a quick table to help you decide:

| Factor | Flip Flow Screens | Banana Screens |

|---|---|---|

| Coal Type | Sticky, wet, fine | Dry, coarse |

| Moisture Content | High | Low |

| Throughput | Moderate to high | High |

| Separation | Precise, less blinding | Good for large volumes |

Tip: If your coal is sticky or wet, Flip Flow Screens save you time and money. If you need speed with dry coal, Banana Screens do the job.

Typical Scenarios

Let’s look at some real-life situations. You run a plant in a region with high rainfall. Your coal comes in wet and clumpy. Flip Flow Screens keep your operation moving. You spend less time cleaning and more time producing.

Maybe your plant handles dry, coarse coal. You want to process as much as possible every hour. Banana Screens help you hit those targets. Their fast-moving design works best when moisture isn’t a problem.

If you need to meet strict specs for fine coal, Flip Flow Screens give you sharp separation. You get cleaner coal and less waste. Plants that focus on quality over quantity often choose Flip Flow Screens.

Here’s a quick list to match your needs:

- Wet, sticky coal: Flip Flow Screens

- High-volume, dry coal: Banana Screens

- Fine coal, strict specs: Flip Flow Screens

- Bulk sorting, simple operation: Banana Screens

Note: Think about your coal type, moisture level, and production goals. The right screen helps you boost efficiency and cut costs.

Industry Trends

Screening Technology Advances

New technology is making coal screening better every year. Flip Flow Screens and Banana Screens are stronger and smarter now. Manufacturers use tough materials and clever designs. These screens last longer and handle hard jobs.

Here are some cool upgrades:

- Designers use big flanges in vibration exciters. This lowers stress on the side plates, so screens stay strong.

- Rivets are used instead of welding. Rivets make side plates tougher and less likely to crack.

- Polyurethane coatings cover the whole screen. This helps stop rust and wear.

- Parts get heated before assembly. This removes stress and helps screens work smoothly.

- Throughput capacity keeps going up. Some screens can handle over 1,500 tons per hour, depending on partition size.

- High acceleration speeds reach up to 50g. This moves material fast and stops clogging.

Both Flip Flow Screens and Banana Screens have these new features. The screens run faster and clean themselves better. You spend less time fixing problems and more time working.

Tip: If you want a screen that fits modern coal plants, look for these features. They make your job easier and your plant more efficient.

Sustainability

You want to help the environment and save money. Flip Flow Screens and Banana Screens use less energy and cut waste. You sort more coal with less effort.

Here’s how these screens help with sustainability:

- You use less energy. The screens run well and don’t waste power.

- You see fewer emissions. Cleaner screening means less dust and fewer pollutants.

- You improve resource efficiency. The screens catch more fine coal, so you waste less.

- You reduce waste. Better separation means less coal ends up in the discard pile.

- You avoid screen blockages. High-performance parts keep the screens running smoothly.

- You benefit from energy-saving features. The screens use smart motors and designs to cut power use.

- You get durable equipment. Strong materials and coatings mean your screens last longer and need fewer replacements.

- You adapt to different coal types. The screens handle sticky, wet, or dry coal without extra energy or cleaning.

| Sustainability Benefit | How It Helps You |

|---|---|

| Reduced energy use | Lower bills, greener operation |

| Less emissions | Cleaner air, safer workplace |

| Improved efficiency | More coal, less waste |

| Durable design | Fewer repairs, less downtime |

Note: When you pick modern screens, your plant runs cleaner and smarter. You also make your operation more sustainable for the future.

Conclusion

You’ve seen that flip flow screens work best for fine, sticky, or wet coal. Banana screens handle high volumes of dry coal. Here’s what you should do:

- Pick flip flow screens for tough, fine coal jobs.

- Choose banana screens for bulk, dry material.

Need a reliable screen? Anpeng Wire Mesh Filter Equipment Co., Ltd. builds tough flip flow screens and more for heavy-duty industries. Reach out today for expert advice or a custom solution!

FAQ

What makes flip flow screens better for fine coal?

You get better results with flip flow screens because they handle fine, sticky, or wet coal without clogging. The elastic surface shakes off lumps and keeps the screen clean. You see less downtime and more accurate separation.

Can banana screens handle wet or sticky coal?

Banana screens struggle with wet or sticky coal. The material can block the screen and slow your process. You will need to clean the screen more often if your coal is damp or clumpy.

How often do I need to clean flip flow screens?

You clean flip flow screens less often. The self-cleaning action of the elastic surface shakes off most stuck coal. You just need to check for wear and tension during routine inspections.

Which screen lasts longer?

Flip flow screens usually last longer. The polyurethane panels resist wear and tear. Banana screens may need more frequent panel replacements, especially if you process sticky or abrasive coal.

Are flip flow screens harder to install?

You might need skilled workers for flip flow screens. The design is a bit more advanced. Once installed, you spend less time on maintenance. Banana screens are simpler to set up but need more cleaning.

Can I switch from a banana screen to a flip flow screen?

Yes, you can switch. You may need to adjust your setup and train your team. Many plants upgrade to flip flow screens for better fine coal separation and less downtime.

What is the main maintenance task for banana screens?

You will spend most of your time cleaning the screen surface. Blinding and pegging happen often, especially with sticky coal. Regular checks and panel replacements keep the screen running.

Do these screens help with dust control?

Flip flow screens help more with dust control. The closed box design keeps coal dust inside. Banana screens have open surfaces, so you may see more dust in the air.