When you pick woven wire mesh sizes for screening, you change how well your work goes. Mesh size tells you how many holes are in one inch. Aperture means the real size of each hole. Wire diameter shows how thick each wire is. These measurements are important in mining, quarry, aggregate, and recycling. They decide how much stuff goes through and how long screens last.

The right mix helps more material pass and keeps screens strong. This way, you get good results every time.

| Term | Description |

|---|---|

| Mesh Size | The number of holes in one inch; bigger numbers mean smaller holes. |

| Aperture | The size of each hole, which decides what can go through. |

| Wire Diameter | How thick each wire is, which affects how strong and tough the mesh is. |

Key Takeaways

- Mesh size tells how many holes are in one inch. Bigger numbers mean the holes are smaller. Smaller holes help filter tiny materials.

- Aperture size shows what can go through the mesh. Pick the right size to screen things well.

- Wire diameter changes how strong the mesh is. Thicker wires make the mesh last longer. Thinner wires let more stuff pass through.

- You need to match mesh count and particle size. This helps stop clogs and keeps things working well.

- Use tools like calipers and micrometers to measure. These tools check aperture and wire diameter to make sure they are correct.

- Pick the right material, like stainless steel, if you need it to last in tough places.

- Think about how you will use the mesh. Different jobs need special mesh features to work best.

- Ask experts like ANPENG for help. They can guide you to pick the best mesh for your work.

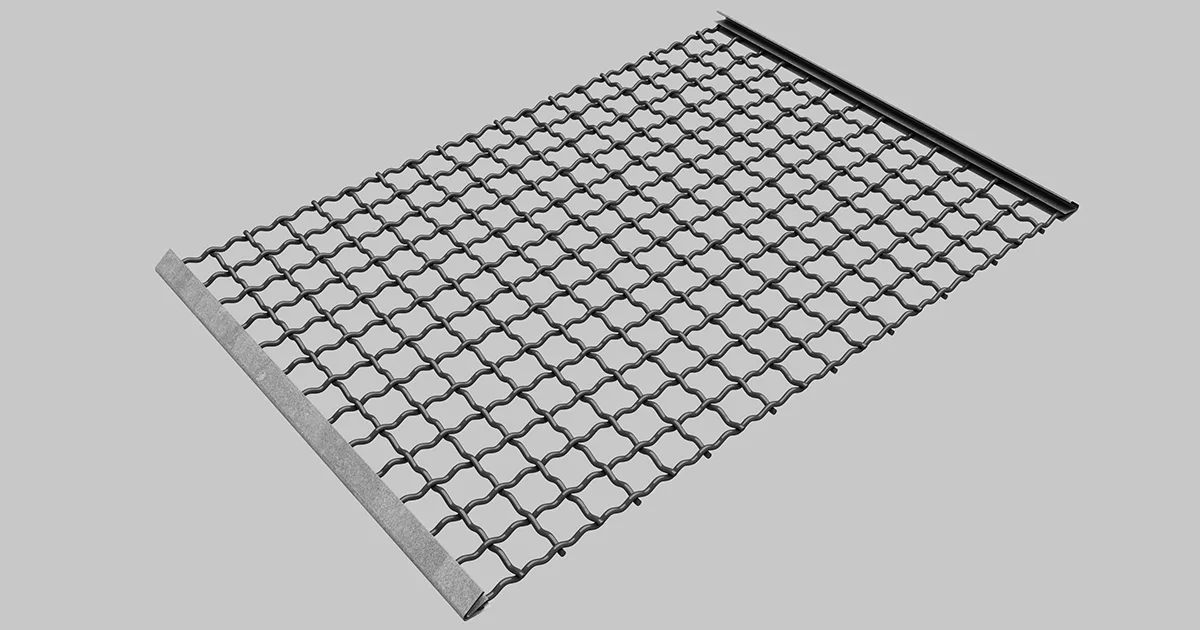

Woven Wire Mesh Sizes Overview

Mesh Size Definition

When you look at woven wire mesh sizes, you see how screens work in real life. You use these screens to sort and separate materials in mining, quarry, aggregate, and recycling. The mesh size tells you how many openings sit in one square inch of woven wire mesh. If you pick a screen with a higher mesh size, you get smaller holes. This means only tiny particles can pass through.

“The term ‘Mesh’ is used to describe the size of an abrasive particle. U.S. Mesh Size (or U.S. Sieve Size) is defined as the number of openings in one square inch of a screen. For example, a 36 mesh screen will have 36 openings while a 150 mesh screen will have 150 openings. The higher the mesh number, the smaller the screen opening and the smaller the particle that will pass through.”

You need to match the mesh size to the job. If you want to catch bigger rocks, you choose a lower mesh size. If you want to filter out fine sand, you go for a higher mesh size. This choice changes how much material you process and how clean your final product looks.

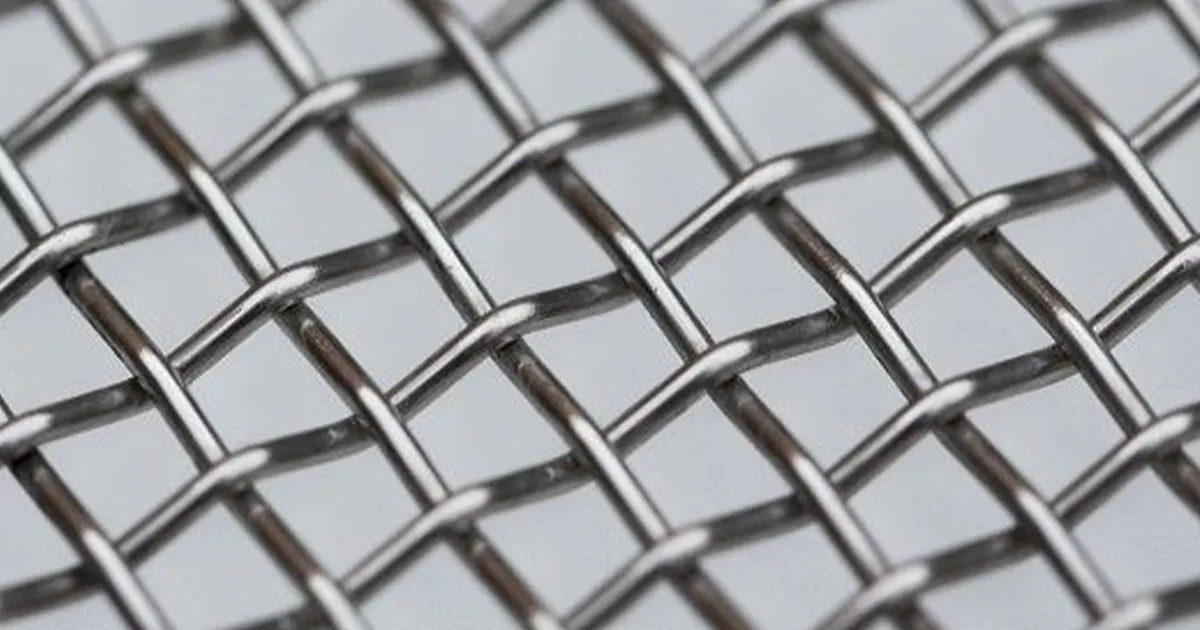

Aperture & Wire Diameter Basics

Woven wire mesh sizes include two main measurements: aperture and wire diameter. The aperture is the actual size of each opening in the mesh. Wire diameter is the thickness of each wire that forms the mesh. Both play a big role in how your screen performs.

Here’s a quick look at how these factors work together:

| Factor | Description |

|---|---|

| Nominal Mesh Size | Actual diameter of the opening on the screening surface. |

| Effective Mesh Size | Size of the product that the mesh produces, typically smaller than the nominal size. |

| Open Area | Ratio of the area of the holes to the screen surface, affecting machine capacity. |

| Mesh Count | Higher counts lead to smaller apertures, increasing precision but risking blockages. |

| Design of Openings | Influences machine efficiency, capacity, and product quality. |

You see how woven wire mesh sizes affect your screening results. If you pick a mesh with a high mesh count, you get smaller apertures. This helps you screen fine materials with more precision. But if you go too high, you might get blockages. You need to balance mesh count with the size of the material you want to screen.

- Higher mesh counts give you smaller apertures and better precision.

- Too many openings can cause blockages, slowing down your work.

- The right mesh count depends on the particle size of your material.

You also need to think about wire diameter. Thicker wires make the woven wire mesh stronger and last longer. Thinner wires give you more open area, which lets more material pass through. You want to find the best mix for your job.

Woven wire mesh sizes come in many standard ranges. You find screens made from stainless steel, high-carbon steel, and other tough materials. These choices help you pick the right woven wire mesh for your needs, whether you work in mining, quarry, aggregate, or recycling.

- The mesh count decides what particle sizes you can screen.

- You need to balance mesh count and material size for the best results.

- Woven wire mesh sizes help you get the right performance for your job.

Measuring Aperture & Wire Diameter

If you want your screening to work well, you need to check both the aperture and wire diameter of your woven wire mesh. You can do this with simple tools and easy steps.

Aperture Measurement Methods

There are a few ways to measure the size of the openings, called aperture, in your mesh. Each way works best for different mesh sizes.

Caliper Use

A caliper is a tool that helps you measure apertures. It works best when the openings are bigger than 4 mm. You put the caliper tips inside the opening and read the number. This way is quick and gives you a good result for bigger mesh sizes.

Visual Inspection

For smaller apertures, you can use a linen tester or an optical scanner. These tools help you see and measure tiny openings that are hard to see with just your eyes. Sometimes, you can use a ruler for a rough guess, but special tools are more exact.

Tip: Always measure a few openings across your mesh. This helps you find any differences and makes sure your mesh is even.

Here is a table that shows common ways to measure aperture and when to use them:

| Method Description | Error Rate |

|---|---|

| Measuring wires loosened from the cloth using a micrometer screw | N/A |

| Measuring wires in the cloth with enough space for the instrument | N/A |

| Optical projection or scanning method | N/A |

| Measuring row method for aperture size | N/A |

| Caliper for measuring aperture sizes over 4 mm | N/A |

| Linen tester for aperture sizes below 1 mm | N/A |

Wire Diameter Measurement

Wire diameter tells you how thick each wire is in your mesh. This changes how strong and bendy your screen will be.

Micrometer Use

A micrometer is the best tool for measuring wire diameter. You put the wire between the jaws and turn the screw until it fits just right. This tool gives you a very exact number. In factories, laser micrometers can measure wire diameter very fast and with high accuracy, even while the mesh is being made.

You should measure at least five wires in both directions, warp and filler, and find the average. This helps you know the real size of your mesh.

| Measurement Procedure | Description |

|---|---|

| Average Diameter Measurement | The average measured diameters of at least five warp and an equal number of filler wires are used for calculations. |

| Use of Precision Tools | Calipers are recommended for accurate measurement of wire diameter. |

Tolerance Factors

Wire diameter measurements can change a little because of how they are made. These small changes are called tolerances. The smaller the wire, the smaller the tolerance. This means you need to be extra careful when measuring thin wires.

| Wire Diameter Range | Tolerance |

|---|---|

| 0.500 and larger | +/-0.0020 |

| Under 0.5000 to 0.3125 | +/-0.0015 |

| Under 0.3125 to 0.0440 | +/-0.0010 |

| Under 0.0440 to 0.0330 | +/-0.0008 |

| Under 0.0330 to 0.0240 | +/-0.0005 |

| Under 0.0240 to 0.0120 | +/-0.0004 |

| Under 0.0120 to 0.0080 | +/-0.0003 |

| Under 0.0080 to 0.0048 | +/-0.0002 |

| Under 0.0048 | +/-0.0001 |

Note: If you want your screens to last longer and work better, always check both aperture and wire diameter. This helps you find problems early and keeps your work going well.

You might have problems like checking for coating thickness, making sure wires are round, or finding defects. Tools like laser micrometers and ultrasonic systems help you measure fast and catch any problems right away.

By using the right tools and checking your mesh often, you make sure your screens stay strong and do their job well.

Mesh Size & Strength

Mesh Count Formula

When you look at woven wire mesh, you see numbers like 10, 20, or 50 mesh. These numbers show the mesh count. Mesh count means the number of openings in one inch of mesh. If you pick a higher mesh count, you get smaller holes. This helps you catch tiny particles. If you choose a lower mesh count, you get bigger holes for larger materials.

- Mesh count tells you how dense the mesh is.

- Higher mesh count gives you better filtering for fine materials.

- Lower mesh count works best for screening bigger solids.

Mesh count affects how much material passes through and how strong your screen stays. If you use a mesh with a high count, you get more wires packed together. This can make the mesh stronger, but it may block material if the holes are too small. You need to balance mesh count with the size of the particles you want to screen.

Tip: Always match mesh count to your job. If you want more strength and load-bearing capacity, pick a mesh with thicker wires and the right count for your material.

Aperture Calculation

Aperture is the size of each opening in your mesh. You can figure out the aperture by measuring the space between two wires. This number helps you know what size particles will pass through.

To calculate aperture, you use this formula:

Aperture (A) = (1 inch / mesh count) - wire diameter (B)

Let’s say you have a mesh count of 10 and a wire diameter of 0.05 inches. The aperture would be:

A = (1 / 10) - 0.05 = 0.1 - 0.05 = 0.05 inches

This means each opening is 0.05 inches wide. You can use this formula to check if your mesh will let the right size material through.

Here’s a table to help you see how aperture and wire diameter work together:

| Component | Description |

|---|---|

| Open Area % | Percentage of the mesh area that is open |

| A | Aperture width (distance between adjacent wires) |

| B | Wire diameter (thickness of the wires) |

| Formula | Open Area % = ((A^2) / (A + B)^2) × 100 |

When you pick the right aperture, you get better screening and more strength. If the aperture is too big, you lose strength and load-bearing capacity. If it’s too small, you might block material and slow down your work.

Open Area Percentage

Open area percentage shows how much of your mesh is open for material to pass through. You want a high open area for faster screening, but you also need enough wire for strength.

You can use this formula to find open area percentage:

Open Area % = ((A^2) / (A + B)^2) × 100

Where:

- A is the aperture width.

- B is the wire diameter.

Let’s look at some examples:

| Mesh Size (Opening) | Wire Diameter | Open Area % |

|---|---|---|

| 1/2″ | 0.063″ | 76.40% |

| 1″ | 0.120″ | 79.72% |

| 2mm | 1mm | 44.44% |

| 1mm | 0.5mm | 44.44% |

| 0.5mm | 0.25mm | 44.44% |

- Higher open area means more material can flow through.

- Lower open area gives you more strength and load-bearing capacity.

- You need to balance open area with wire diameter to get the best performance.

If you want your mesh to last longer and handle heavy loads, pick a mesh with thicker wires and a lower open area. If you need fast screening, choose a mesh with a higher open area. Always think about the strength you need for your job.

Note: The right mix of mesh count, aperture, and wire diameter gives you the strength and load-bearing capacity you need. It also helps you get the best screening results.

Wire Diameter Impact on Strength

When you choose woven wire mesh, you need to think about wire diameter. This is the thickness of each wire in your mesh. Wire diameter plays a big role in how strong and tough your screen will be. If you pick a thicker wire, your mesh can handle more weight and pressure. Thicker wires also last longer, especially when you use them in tough jobs like mining or construction using wire mesh.

You might wonder why not always pick the thickest wire. Here’s the catch: thicker wires make your mesh stronger, but they also make the holes smaller. This means less material can pass through at once. If you need to screen a lot of material quickly, you may want a thinner wire. Thinner wires give you more open area, so more material flows through. But, thinner wires can wear out faster and may not hold up under heavy loads.

Let’s break it down:

- Thicker wire diameter = more strength, better durability, less open area.

- Thinner wire diameter = more open area, faster flow, but less strength.

You can see this in the table below:

| Wire Diameter | Mesh Strength | Open Area | Durability |

|---|---|---|---|

| Thick | High | Low | High |

| Thin | Low | High | Low |

Tip: Always match the wire diameter to your job. If you need your mesh to last a long time and handle heavy rocks or sharp materials, go for a thicker wire. If you want to screen fine sand or light materials quickly, a thinner wire might work better.

The gauge size tells you how thick the wire is. A lower gauge number means a thicker wire. For example, 8 gauge is thicker than 16 gauge. Always check the gauge size before you buy your mesh. This helps you pick the right balance between strength and open area.

Wire diameter is not just about strength. It also affects how your mesh handles high-pressure loads and tough conditions. If you use the wrong wire diameter, your mesh might bend, break, or wear out too soon. You want your screen to last and do its job well, so always pay attention to wire diameter.

In short, wire diameter is a key part of mesh design. It decides how strong, durable, and efficient your screen will be. Take your time to choose the right wire diameter for your work. This way, you get the best results and avoid costly problems.

Standard Woven Wire Mesh Sizes

Common Mesh Counts & Apertures

When you look for woven wire mesh, you see many choices for mesh counts and aperture sizes. Mesh count tells you the number of holes per inch in your screen. This number helps you decide what size particles will pass through. In mining, quarry, aggregate, and recycling, you often use heavy-duty screens with mesh counts between 20 and 50. These screens have aperture sizes that match tough jobs and large materials.

Here’s a quick table to show you some typical mesh counts and aperture sizes:

| Mesh Count | Aperture Size (mm) |

|---|---|

| 20 | Heavy-duty screens |

| 30 | Heavy-duty screens |

| 40 | Heavy-duty screens |

| 50 | Heavy-duty screens |

If you need to sort fine sand, you pick a higher mesh count. If you want to screen rocks, you choose a lower mesh count. The number of holes per inch changes how your screen works. You also need to check wire mesh gauges to make sure your screen is strong enough for your job.

Standard Widths & Sheet Sizes

You can buy woven wire mesh in many standard widths and sheet sizes. These options help you fit screens into your machines without much trouble. You see sheets as small as 150 x 150mm and as large as 1000 x 1000mm. Rolls come in lengths like 5 or 10 meters, with a width of 1000mm. This makes it easy to cover big areas or cut mesh to fit your needs.

Here’s a table with some common sheet and roll sizes:

| Sheet Size | Description |

|---|---|

| 150 x 150mm | 2 Pack |

| 210 x 300mm | A4 x 4 Pack |

| 300 x 300mm | 30 x 30cm Sheet |

| 300 x 420mm | A3 x 3 Pack |

| 500 x 500mm | 50 x 50cm Sheet |

| 420 x 594mm | A2 Sheet |

| 594 x 841mm | A1 Sheet |

| 1000 x 500mm | 100 x 50cm Sheet |

| 1000 x 1000mm | 100 x 100cm Sheet |

| 5 Metre x 1000mm | 1 Metre Roll |

| 10 Metre x 1000mm | 1 Metre Roll |

You can pick the right size for your project. If you need a custom fit, you can cut sheets or rolls to match your machine. Always check wire mesh gauges before you buy. This helps you get the right strength and durability.

Material Options

You have many choices for wire mesh materials. Stainless steel is popular because it resists heat and corrosion. It lasts a long time, even in tough jobs. The 300 series stainless steel, like 304 and 316, gives you special chemical properties for different uses. The 400 series stainless steel has more carbon, so it is stronger and works well for magnetic jobs.

Here’s a table to help you compare material options:

| Material Type | Advantages |

|---|---|

| Stainless Steel | Excellent heat resistance, corrosion resistance, durability in high-impact applications, cost-effective. |

| 300 Series Stainless | Variants like 304 and 316 offer specific chemical compositions for various applications. |

| 400 Series Stainless | Increased durability due to higher carbon content, suitable for magnetic applications. |

You might see other materials, but stainless steel is the top choice for most industrial screening. If you want the best results, you should look at ANPENG’s industrial screening products. ANPENG offers woven wire mesh in many wire mesh gauges and holes per inch options. You get strong, reliable screens for mining, quarry, aggregate, and recycling.

Tip: Always match your wire mesh gauges and holes per inch to your job. This helps you get the right strength, durability, and performance.

If you need help picking the right mesh, ANPENG can guide you. You get expert advice and high-quality products for every screening need.

Choosing Woven Wire Mesh for Industrial Screening

Application Factors

When you pick woven wire mesh, think about how you will use it. Different jobs need different mesh features. If you work in mining, quarry, aggregate, recycling, or construction, you need mesh that fits your job. Some mesh is good for surface filtration. This means it catches particles on top and is easy to clean. Other mesh is for depth filtration. It traps particles inside the layers. Sieve filtration sorts materials by size. People use this in food factories and some industrial jobs.

Here are some important things to think about:

- Opening size should match the particles you want to filter or screen.

- Wire diameter changes strength and how long the mesh lasts. Thicker wires last longer in tough jobs.

- Material choice is important. Stainless steel can handle chemicals and heat. Galvanized steel costs less money.

- Open area percentage changes how fast material moves through.

- Mesh type can be woven or welded. Woven mesh bends and works for many jobs. Welded mesh is more stable.

You also need to think about where you use the mesh. If your mesh faces chemicals or very hot or cold places, pick stainless steel or coated mesh. This makes it last longer. Always check that your mesh meets ASTM, ISO, and OSHA rules for safety and quality.

Matching Mesh Size to Material

Getting the right mesh size for your material makes screening work better. If your mesh matches the size of your particles, you can separate them well. This helps you sort materials into smaller pieces and makes your final product better. In mining and aggregate work, the right mesh size keeps waste low and helps you use resources well.

| Evidence Description | Key Points |

|---|---|

| Screening equipment is designed to sort materials into finer grades. | Proper mesh size allows for effective separation of particles based on size, enhancing efficiency. |

| The efficiency of screening is influenced by material type and screen design. | Correct mesh size minimizes waste and optimizes resource allocation. |

| Proper material screening enhances structural integrity. | Consistent product quality is crucial for durability in construction. |

If you use mesh for fencing, you want to keep animals out but let air and light in. For recycling, matching mesh size to the material helps you sort plastics, metals, or glass fast. In construction, good mesh size keeps your products strong and safe.

- Matching mesh size to material type helps you separate things well.

- It cuts down on waste and makes your results more even.

- You get better results in all jobs, from mining to fencing.

Selection Guidance

Picking the right mesh size and wire diameter depends on your job. You want to balance strength, weight, and cost. Thicker wires make the mesh stronger but also heavier and more expensive. Mesh size must hold your material without letting it fall out. If the mesh is too fine, it can slow down how fast liquids move.

| Factor | Consideration |

|---|---|

| Wire Diameter | Balance between strength and weight; thicker wires increase weight and cost. |

| Mesh Size | Must contain parts without allowing egress; too fine can impede fluid flow. |

| Industry-Specific Needs | Different industries (e.g., automotive, medical) have unique requirements for wire and mesh. |

If you need fencing for a farm, pick mesh with openings that keep animals in but let wind go through. For tough jobs in mining, choose mesh with thick wires and strong materials. Always check the rules for your industry to make sure your mesh is safe and works well.

Tip: Talk to a mesh expert if you are not sure. They can help you pick the best mesh for your job, like fencing, recycling screens, or mining equipment.

You get better results when you match mesh size and wire diameter to your needs. This helps your screens last longer and work better in all jobs.

Mesh Size Examples in Real Applications

Aggregate Screening

When you work with aggregate, you need to pick the right mesh for your screen. The type of aggregate changes how you set up your mesh and the results you get. For example, angular stones roll less, so you use a mesh with smaller openings. Rounded stones move more, so you might need a mesh with bigger holes. You also need to think about the tilting angle of your screen. If you use small aggregate, a steeper angle helps the material move faster. For middle or large aggregate, a lower angle works better.

Here’s a table that shows how different aggregate types match with mesh and screen settings:

| Aggregate Type | Rolling Distance Interval (m) | Suitable Tilting Angle (°) |

|---|---|---|

| Angular | 0.0 – 0.6 | N/A |

| Sub-angular/Sub-rounded | 0.6 – 1.2 | 20 |

| Rounded | 1.2 – 1.8 | N/A |

| Small Aggregate | N/A | 25 |

| Middle/Large Aggregate | N/A | 20 |

Tip: If you want clean and even aggregate, match your mesh size to the shape and size of your material. This helps you get better results and keeps your screen working longer.

Recycling Operations

In recycling, you use mesh to sort materials like glass, plastic, and metal. You need a mesh that can handle sharp edges and heavy loads. If you pick a mesh with small openings, you can separate fine particles like crushed glass. For bigger pieces, you use a mesh with larger holes. You also want a mesh with strong wires so it does not wear out fast.

You might use a woven wire mesh for sorting plastics. This mesh lets you separate small flakes from bigger chunks. For metal recycling, you need a mesh that can stand up to tough conditions. Stainless steel mesh works well because it resists rust and damage. You can also use mesh screens with self-cleaning features to keep your operation running smoothly.

- Use small mesh openings for fine materials.

- Pick thicker wires for heavy or sharp materials.

- Choose stainless steel mesh for long-lasting screens.

Note: The right mesh helps you sort more material and keeps your recycling line moving fast.

Mining Applications

Mining jobs need strong mesh screens that can handle rocks, dirt, and heavy impact. You use different mesh sizes depending on where you place the screen. In rockfall areas, you need mesh with thick wires, like 8 gauge or more. This mesh is very strong and can hold back large rocks. In less critical spots, you might use a 2mm gauge mesh. This mesh gives you a balance between strength and opening size.

Here’s a table that shows how mesh size matches mining jobs:

| Mesh Size | Application | Characteristics |

|---|---|---|

| 8 gauge or thicker | Rockfall areas | Most robust and dense characteristics |

| 2mm gauge | Less critical areas | Compromise between strength and opening size |

| Larger diameter wires | High impact zones | Affects screening classification capability |

| Smaller opening meshes | Dynamic zones | Optimized for impact energy |

If you work in high-impact zones, you need mesh with larger diameter wires. This mesh can take more hits and lasts longer. In dynamic zones, you use mesh with smaller openings. This mesh helps you control the flow of material and keeps your operation safe.

If you want the best mesh for mining, look at ANPENG’s industrial screens. You get strong mesh that stands up to tough jobs and keeps your site safe.

Conclusion

Choosing the right woven wire mesh size is essential for consistent screening performance. Aperture controls the cut size, wire diameter affects strength and wear life, and mesh count/open area influences throughput and efficiency—especially in mining, quarry, aggregate, recycling, and construction applications.

As a manufacturer of woven wire screens and industrial screening media, ANPENG can recommend the best specification based on your material size, moisture, capacity, and screen deck setup. Send us your required opening (mm/inch), wire diameter, panel size, and operating conditions—we’ll provide a tailored recommendation and a fast quotation.

FAQ

What does gauge mean in woven wire mesh?

Gauge tells you how thick each wire is in your mesh. A lower gauge means a thicker wire. You can check the gauge to know how strong and durable your screen will be.

How do I choose the right gauge for my screening job?

You should match the gauge to your material. Heavy rocks need a lower gauge for strength. Fine sand works well with a higher gauge. Always check your machine’s needs before you pick a gauge.

Does gauge affect mesh strength?

Yes! Gauge changes how tough your mesh is. A lower gauge gives you more strength and lasts longer. If you use a higher gauge, you get more open area, but the mesh may wear out faster.

Can I use the same gauge for all materials?

No, you can’t. Hard materials need a lower gauge for extra strength. Softer or lighter materials work with a higher gauge. Always match the gauge to your job for the best results.

How do I measure gauge on my mesh?

You can use a micrometer or caliper to measure the wire. Then, check a gauge chart to find the number. Always measure a few wires to make sure your mesh is even.

Why do mesh size and gauge matter together?

Mesh size tells you how big the holes are. Gauge tells you how thick the wires are. You need both to get the right balance of strength and open area for your screening job.

What happens if I pick the wrong gauge?

If you pick a gauge that’s too thin, your mesh can break or wear out fast. If you pick a gauge that’s too thick, you lose open area and slow down your screening. Always choose the right gauge for your work.

Is there a standard gauge for industrial screens?

No single gauge fits every job. Common gauges for heavy-duty screens are 8, 10, or 12. For lighter jobs, you might use a higher gauge. Always check your industry’s standards and talk to a mesh expert if you’re not sure.