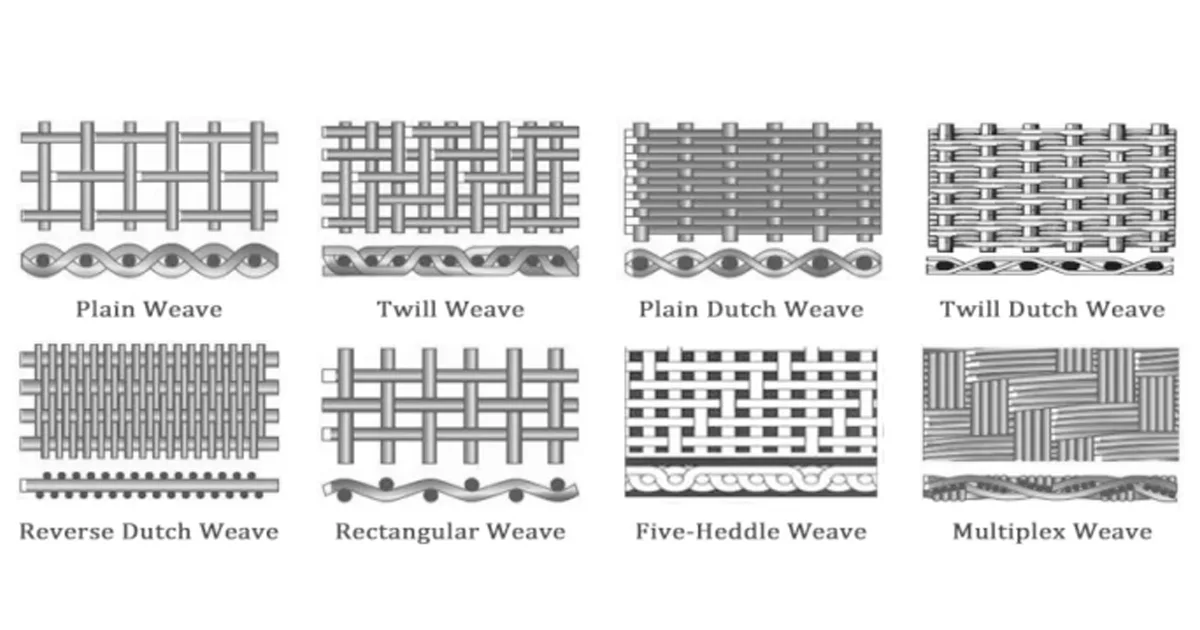

Woven wire mesh is a useful material in many fields. People use it to screen, filter, and protect machines. There are different woven wire mesh types. These include plain crimp, intercrimp, lock crimp, flat top crimp, and Dutch weaves. Each type has its own pattern and strength. Lock crimp gives more stability. Flat top crimp helps materials move more easily. The woven wire mesh market is growing around the world. Most demand comes from construction, cars, mining, and airplanes. Picking the right weave and material is important for how well it works and how long it lasts. This guide helps people choose the best mesh type for their needs.

Key Takeaways

- Woven wire mesh has many types. Some types are plain weave, lock crimp, and Dutch weave. Each type is used for different jobs.

- Picking the right mesh type is very important. It helps with filtration, screening, and protection. These jobs are needed in construction, mining, and food processing.

- Plain weave mesh is strong and flexible. People use it a lot for filtration and barriers.

- Lock crimp mesh is very stable. It works well for heavy-duty jobs. It is good for security and building designs.

- Intercrimp mesh is stiff and exact. It is great for industrial filtration and screening.

- Flat top crimp mesh has a smooth surface. Materials can slide on it easily. It is useful in mining and food processing.

- The material you pick is important. Stainless steel does not rust. Galvanized steel costs less and works well outside.

- When you order woven wire mesh, say what you need. Pick the right weave type. Share your details to get the best results.

Main Woven Wire Mesh Types

Plain Weave Mesh

Structure and Features

Plain weave is a very common woven wire mesh type. It uses a simple over-under pattern. Each warp wire goes over and under each weft wire. This makes a grid with square openings. Plain weave is flexible but also strong. It does not use a complex pattern like twilled weave. The crossing stays simple and stable. This helps the mesh stay steady and easy to use.

- The wires go over and under in turns.

- Square openings give both strength and accuracy.

- The mesh is flexible and tough.

- Plain weave keeps a basic, steady crossing.

Common Uses

Plain weave mesh works for many jobs because it is balanced. It is good for factories and decoration. The table below lists popular ways people use this mesh:

| Application Type | Description |

|---|---|

| Filtration and Separation | Used to filter liquids, gases, and powders in chemical and food factories. |

| Screening and Sieving | Used in mining and farming to sort and grade particles. |

| Protective Barriers | Used for machine guards and fences to keep people safe and let them see through. |

| Architectural and Decorative | Makes buildings, ceilings, and furniture look nice. |

| Electronics and Electrical | Used for shielding and filters in sensitive electronics. |

| Industrial Applications | Used for air vents and screens in machines. |

| Marine Applications | Does not rust in seawater, so it is good for marine barriers. |

| High-Temperature Applications | Can handle high heat in furnaces and heat exchangers. |

Many companies like ANPENG use plain weave mesh in wire screens for sorting, filtering, and protecting machines.

Lock Crimp Mesh

Structure and Features

Lock crimp mesh is made for strength and stability. The wires have a special crimp that locks them at each crossing. This lock makes the mesh stronger and stops wires from moving. People pick lock crimp when they want tough mesh that looks neat.

- The crimp locks wires tightly together.

- The mesh is very stable and strong.

- This type is good for heavy work and decoration.

Common Uses

Lock crimp mesh is used in places that need strong mesh. The table below shows where this mesh works best:

| Industry | Application Description |

|---|---|

| Security | Used for fences, machine guards, and window screens to keep things safe. |

| Architectural | Good for railings in stairs, balconies, and walkways to make them safe and look nice. |

| Decorative Facades | Makes building outsides and room dividers look modern. |

Lock crimp mesh is great for building projects and panels that hold heavy loads. Many makers like ANPENG sell lock crimp wire screens for tough jobs.

Intercrimp Mesh

Structure and Features

Intercrimp mesh has extra crimps at each wire crossing. These extra crimps make the mesh stiff and help hold thin wires in place. This design lets the mesh have square or rectangle openings in different sizes. The tight crimps keep the mesh steady and accurate. People use it when they need mesh that is strong and precise.

Common Uses

Intercrimp mesh is used in many industries. Its stiff shape and tight holes make it good for hard jobs. Here are some common uses:

| Application Type | Description |

|---|---|

| Screening and Separation | Used in mining, rock, and recycling because it is stiff and does not clog easily. |

| Industrial Filtration | Needed for filtering materials in many factory jobs. |

| Architectural Design | Used in building designs for looks and function. |

| Security Fencing | Keeps places safe and secure. |

| Animal Enclosures | Used to make safe spaces for animals. |

| Barbecue Grills | Food-safe mesh is used for grilling food. |

| Reinforcement in Composites | Helps make composite materials stronger. |

Intercrimp mesh is often used in wire screens for mining and recycling. It is chosen when strength and not getting clogged are important.

Flat Top Crimp Mesh

Structure and Features

Flat top crimp mesh has a smooth surface. One side of the wires is flat. The other side has crimps that hold the mesh together. This design lets materials slide across easily. Things do not get stuck or caught. The mesh stays strong and keeps its shape. It works well for heavy jobs.

- The top feels smooth and flat.

- The mesh lasts a long time and does not wear out fast.

- It can hold heavy things without bending.

- The open spaces stay the same for good screening.

Flat top crimp mesh is good when things need to move easily. The smooth surface helps stop damage to products. It also keeps the mesh clean.

Common Uses

Flat top crimp mesh is used in many places. It is great for screening, sorting, and protecting machines. Here are some ways people use it:

- Mining and Quarrying: Used in screens that shake to sort rocks and minerals. The smooth top helps things move off fast.

- Food Processing: Stops food from sticking during sorting and washing.

- Construction: Used to make concrete stronger and as safety barriers.

- Industrial Screening: Works well in screens that clean themselves and heavy-duty wire screens, like those made by ANPENG.

Flat top crimp mesh helps companies do better at screening and sorting. Its smooth surface and strong build make it good for hard jobs.

Twill Weave Mesh

Structure and Features

Twill weave mesh uses a special pattern. The wires go over two and under two. This makes a diagonal look. The pattern gives the mesh more strength and flexibility. The diagonal lines help the mesh hold heavy loads. It also resists damage. Twill weave mesh clogs less, so it is good for fine filtration.

- The mesh has a diagonal, interlocking pattern.

- It bends but does not break and stays strong.

- It holds heavy loads better than plain weave.

- The mesh does not clog easily, so cleaning is simple.

Twill weave mesh is used in many industries. It is good for filtering, screening, and protecting machines. The table below shows where twill weave mesh is used:

| Application Type | Description |

|---|---|

| Filtration and separation | Used for filtering liquids and gases, oil refining, water cleaning, and chemical jobs. |

| Screening and sieving | Used in mining, medicine, food jobs, and powder making for sizing. |

| Protective and reinforcement structures | Used as shields, layers for strength, or barriers in factories. |

| Heat and corrosion-resistant components | Good for furnaces, heat exchangers, and catalyst supports. |

| Aerospace and defense | Used where things need to be strong, light, and resist heat. |

Twill weave mesh helps companies like ANPENG make strong and flexible wire screens. It is a top pick for places that need strength and fine filtration.

Dutch Weave Mesh

Structure and Features

Dutch weave mesh uses a tight weaving pattern. The wires are close together. This makes the mesh good for fine filtration. The tight weave filters out very small bits. Dutch weave mesh is more precise than regular square mesh. It stays strong under pressure. It works well for tough jobs.

Dutch weave mesh is best for industries that need clean and pure results. The mesh can handle pressure and keeps its shape. It works even when filtering thick or dirty liquids.

Common Uses

Many industries use Dutch weave mesh for important filtration jobs. Here are some main ways it is used:

- Petrochemical and Chemical Processing: Separates solid bits from liquids and gases.

- Pharmaceutical and Biotechnology: Keeps products pure with careful filtration.

- Food and Beverage Processing: Filters oil, syrup, and keeps things clear.

- Water Treatment and Environmental Protection: Removes tiny dirt and sludge in treatment plants.

- Automotive and Mechanical Engineering: Protects machines in hydraulic and fuel systems.

- Mining and Metallurgy: Takes out impurities during mineral and metal work.

- Power Generation and Manufacturing: Filters oils and keeps machines safe.

Dutch weave mesh helps companies meet strict rules for cleanliness and safety. ANPENG makes Dutch weave wire screens for industries that need good and accurate filtration.

Twilled Dutch Weave Mesh

Structure and Features

Twilled Dutch weave mesh is special because of its weaving style. The wires go over and under two or more wires. This is different from just going over one wire. The pattern makes the mesh thick and strong. The wires are packed close together. This gives the mesh more strength and helps it filter tiny things. People pick this mesh when they need to catch very small particles. It also lets liquids or air move through easily.

Here is a table that shows how twilled Dutch weave mesh and standard Dutch weave mesh are different:

| Feature | Twill Dutch Weave Mesh | Standard Dutch Weave Mesh |

|---|---|---|

| Structural Strength | Superior due to tighter, denser weave | Standard strength |

| Filtration Precision | Exceptional, handles finer particles | Less precise |

| Flow Rates | High flow rates despite fine filtration | Moderate flow rates |

| Durability | High-quality materials, resistant to wear | Varies based on material |

Twilled Dutch weave mesh keeps its shape even when pressed hard. It does not wear out fast and lasts a long time. This is why people use it for hard jobs in factories and labs.

Common Uses

Twilled Dutch weave mesh is good for jobs that need both strength and fine filtering. Many industries use it because it can handle tiny bits and high pressure. Here are some common ways people use it:

| Application Area | Description |

|---|---|

| Chemical Processing | Used for filtering and separating when careful filtering is needed. |

| Aerospace | Good for engine parts and filters because it is strong. |

| Pharmaceutical Industry | Used where things must be very pure. |

Factories use twilled Dutch weave mesh in their filters. ANPENG sells this mesh for places that need good and careful screening, like chemical plants and labs. The mesh is also used in airplane parts, where strength and accuracy are important.

Square Mesh vs. Filter Cloth

Key Differences

Square mesh and filter cloth are used for different jobs. Square mesh has open, square holes. Filter cloth has a tighter weave for better filtering. The main difference is how each one handles particles and flow.

Here is a table that shows the main differences:

| Feature/Use | Square Mesh Applications | Filter Cloth Applications |

|---|---|---|

| General Use | Screens larger particles and contaminants | Filters finer particles and allows adequate flow |

| Industry Examples | Plastic extrusion, die casting, protective filter layers | Automotive, medical, and plastic extrusion industries |

| Durability Requirement | Best for maximum durability in screening aggregates | Best for filtering finer particles with specific cut-points |

Square mesh is best for sorting bigger pieces or keeping machines safe. Filter cloth is better for catching tiny bits.

Application Areas

People choose square mesh or filter cloth based on what they need. Square mesh is used in mining, building, and plastic factories. It helps sort rocks, sand, and other big things. ANPENG’s woven wire screens use square mesh for these tough jobs.

Filter cloth is best for jobs that need fine filtering. Car makers, medical companies, and plastic factories use filter cloth to keep things clean and pure. ANPENG gives filter cloth to these industries and makes sure it meets strict rules.

Tip: When you pick between square mesh and filter cloth, think about the size of the particles you want to filter and how strong the mesh should be. This will help you choose the right one for your job.

Key Weave Types and Their Characteristics

Mesh Opening and Shape

Mesh opening and shape are important for how well woven wire mesh works. The size and shape of each opening decide what goes through and what gets stopped. People check wire thickness, mesh count, and opening size to find the best mesh for their job. Here are some things to remember:

- Thicker wires make smaller openings if the mesh count stays the same. This makes the mesh stronger but lets less stuff pass through.

- Thinner wires make bigger openings. This helps things flow better and makes filtering easier, but the mesh may not last as long.

- Mixing wire thickness, mesh count, and opening size helps get good filtering and screening.

When picking mesh, people should think about what needs to go through and how strong the mesh should be. For example, ANPENG’s woven wire screens use different opening sizes to sort rocks, sand, or food.

Tip: Always look at the mesh opening size before you buy. This helps make sure the mesh will work for your job.

Strength and Stability

Mesh strength and stability depend on many things. Each thing changes how the mesh works in hard jobs like mining or building. The table below shows what matters most:

| Factor | Description |

|---|---|

| Material Selection | Picking the right material is important, especially for high heat or harsh chemicals. |

| Mesh Count | More openings per area can change both strength and filtering ability. |

| Wire Diameter | Thicker wires mean more strength and longer life. |

| Weave Type | The pattern of the weave changes how stable and strong the mesh is. |

| Application-Specific | Each job has its own needs, so the mesh must match those needs. |

| Temperature | Some materials, like stainless steel, work better in hot places. |

| Corrosive Influences | Some jobs need mesh that resists rust or chemicals. |

| Fluid Viscosity | The thickness of the liquid or gas affects which mesh works best. |

| Particle Size | The size of what you want to filter decides the mesh count and opening size. |

| Pressure Drop Standards | The mesh must handle changes in pressure as things move through it. |

| Flow Rates | The mesh should let the right amount of material pass through. |

| Pollutant Varieties | Different pollutants need different mesh designs. |

| Specific Gravity | The weight of the material being filtered can change the mesh choice. |

People who use ANPENG’s screening media look at these things to pick the best mesh for their machines.

Flexibility and Adaptability

Flexibility and adaptability make woven wire mesh special compared to welded mesh. This helps for jobs that need bending or shaping. The table below compares woven and welded mesh:

| Feature | Woven Wire Mesh | Welded Wire Mesh |

|---|---|---|

| Flexibility | Highly flexible, can bend and shape | Rigid, less adaptable |

| Applications | Curved filters, decorative elements | Stable structures |

| Terrain Conformity | Conforms to uneven surfaces | Limited adaptability |

Woven wire mesh fits into small spaces and wraps around curves. People use it for custom filters, curved screens, and cool building designs. Its flexibility means it works for jobs where other mesh types cannot. This is very important for industries like mining, food processing, and architecture.

- Woven mesh bends and shapes without breaking.

- It works for custom jobs and rough ground.

- Many companies pick it for both work and looks.

Note: If a project needs mesh that bends or fits odd shapes, woven wire mesh is the best pick.

Woven Wire Mesh Materials

Stainless Steel Mesh

Corrosion Resistance

Stainless steel mesh does not rust or corrode easily. Many people use it in tough places, like chemical plants or near the sea. The steel has special parts inside. For example, 316 stainless steel has molybdenum. Molybdenum helps stop pitting and crevice corrosion. This is good when the mesh touches saltwater or chemicals. Stainless steel mesh keeps its shape and lasts a long time. People trust it for jobs where water or chemicals might hurt other materials.

- Stainless steel mesh does not rust in wet or salty places.

- 316 stainless steel has molybdenum to fight corrosion.

- It works well in chemical plants, food factories, and marine screens.

Tip: Use stainless steel mesh for outdoor or chemical jobs. It keeps screens strong and safe.

Durability

Stainless steel mesh is strong and tough. The wires can handle heavy use. This makes it good for mining, building, and screening. Stainless steel mesh stays strong for many years. Sun, rain, and chemicals do not break it down. Many companies, like ANPENG, use stainless steel in their wire screens because it lasts so long.

- The steel makes the mesh very durable.

- Mesh does not get damaged by weather, chemicals, or heavy loads.

- It needs little care, which saves time and money.

Galvanized Steel Mesh

Cost and Outdoor Use

Galvanized steel mesh costs less than stainless steel. It is about one-fourth to one-fifth the price. The mesh has a zinc coating. Zinc helps protect it from rust. This makes it good for outdoor fences, garden screens, or barriers. It does not last as long as stainless steel, but it works well for many outdoor jobs. People pick galvanized mesh when they want to save money and still get some rust protection.

- Galvanized mesh is cheaper than stainless steel.

- Zinc coating helps stop rust outside.

- It works for fences, cages, and construction screens.

Note: Stainless steel mesh lasts longer for hard outdoor jobs, but galvanized mesh is a good choice for lighter use.

Brass and Bronze Mesh

Aesthetic and Conductivity

Brass and bronze mesh look nice and work well. Bronze mesh is made from copper alloys. It has a special color and does not rust like steel. Over time, it gets a patina, which many people like. Bronze mesh is used for decoration, art, and building features.

Brass mesh is good for electrical jobs. It conducts electricity well and does not rust easily. People use it for shielding, filtering, and decoration. Both brass and bronze mesh are pretty and useful. ANPENG can give these meshes for projects that need both looks and performance.

| Material | Key Features | Common Uses |

|---|---|---|

| Bronze Mesh | Special color, resists corrosion, gets patina | Decorative screens, art, marine uses |

| Brass Mesh | Good at conducting electricity, resists corrosion | Filtration, shielding, decoration |

For projects that need style and performance, brass and bronze mesh are great picks.

Specialty Materials

Nickel, Titanium, Others

Some jobs need woven wire mesh that works in tough places. Specialty materials like nickel and titanium help with these hard jobs. These metals make the mesh stronger. They work where steel or brass might not.

Nickel mesh is good at handling heat and chemicals. It does not rust much. People use nickel mesh in chemical plants and batteries. It also works in places with high heat. Nickel mesh helps in water treatment and fuel cells. It keeps its shape when things get hot or rough.

Titanium mesh is light and strong. It does not rust, even in seawater. This makes it great for marine screens and medical filters. It is also used in aerospace parts. Titanium mesh stands up to acids and chemicals. People use it when safety and long life are important.

Other specialty materials include alloys like Monel and Inconel. These meshes work in oil refineries and power plants. They also help in labs. These alloys handle acids, heat, and pressure. Some can block sparks or shield against waves.

Here are some ways people use specialty woven wire mesh:

- Industrial safety and security: Nickel or titanium mesh protects windows and cages. It can block sparks from machines.

- Agricultural uses: Specialty mesh keeps crops safe and builds barriers for animals. It also stops pests.

- Architecture and interior design: Designers use these meshes for panels and wall covers. Titanium or nickel mesh adds style to buildings.

A table below shows how these specialty materials are different:

| Material | Key Strengths | Typical Uses |

|---|---|---|

| Nickel | Handles heat and chemicals | Chemical plants, batteries, water filters |

| Titanium | Light, strong, rust-proof | Marine screens, medical, aerospace |

| Monel, etc. | Handles acids and high heat | Oil, power plants, labs |

Tip: If a project needs mesh for heat, chemicals, or a special look, nickel and titanium are good choices.

ANPENG makes woven wire screens and panels from these strong materials. These products help industries fix hard problems and keep workers safe. Specialty mesh is used when regular mesh cannot do the job.

Applications of Woven Wire Mesh

Industrial Filtration

Woven wire mesh is important for cleaning in factories. Many places use it to filter liquids and gases. The mesh takes out dirt and solids from these materials. Different jobs need different mesh types for filtering. Plain weave and Dutch weave mesh are good for fine filtration. ANPENG makes screens that work well for these uses.

Here is a table that shows where woven wire mesh is used most for industrial filtration:

| Industry Sector | Percentage | Applications |

|---|---|---|

| Petrochemical & Oil & Gas | 30% | Pre-filtration, process fluid filtration, fuel filtration |

| Water Treatment | 25% | Wastewater, potable water, desalination pre-treatment |

| Food & Beverage | 15% | Clarification, syrup filtration, process water filtration |

| Pharmaceutical & Biotech | 10% | Buffer filtration, solvent recovery |

| Machinery & Hydraulics | 10% | Lubrication oil filtration, hydraulic fluid cleaning |

| Other Industrial Processes | 10% | Pulp & paper, mining, power generation |

Woven wire mesh works well because it can handle strong pressure and tough chemicals. Mesh screens from ANPENG are strong and last a long time. They help machines work better and keep products safe.

Architectural and Decorative

Architects and designers like woven wire mesh for its look and strength. It is used for many building and decoration jobs. People use mesh for fences, wall panels, and ceilings. Mesh works inside and outside buildings. It can cover walls, block sunlight, or make garden walls. Some people use mesh for fountain covers, air vents, and walkways. Mesh is also used for bike paths, room dividers, screens, window and door covers, cabinets, lights, and signs.

Woven wire mesh is popular because it is easy to put in and lasts a long time. It does not get damaged by heat, water, fire, or rust. Mesh made from copper or stainless steel looks nice and works well for fancy projects. Special weave types make buildings and public spaces look stylish. ANPENG gives mesh that is safe and looks good, so architects like to use it.

Security and Safety

Woven wire mesh helps keep people and things safe. Many companies use it for security. Mesh guards protect workers from dangerous machines but let them see through. Mesh panels make barriers in risky places and keep people safe. Wire mesh cages stop people from getting to valuable or dangerous things. In factories, safety mesh panels stop falls and protect workers and equipment. Mesh fences keep buildings and work sites safe from intruders.

Woven wire mesh is good for safety because it is strong and bends easily. It lets people see and air move while blocking danger. ANPENG’s mesh screens and panels are great for guarding machines, stopping falls, and keeping places secure. Mesh can be shaped for many jobs, so it is a smart choice for safety in many industries.

Agricultural and Food Processing

Woven wire mesh plays a big role in agriculture and food processing. Farmers and food companies use it to keep crops safe, sort produce, and make sure food stays clean. Mesh screens help with airflow, letting crops dry out while blocking bugs and pests. Sunlight passes through the mesh, so plants get the light they need. Stainless steel mesh stands up to rain and sun, protecting crops from damage.

Food factories use woven wire mesh in many ways. Mesh conveyor belts move food through cooling, drying, or freezing steps. These belts let air flow all around, which helps food cool or dry evenly. Mesh baking trays give bread and pastries a crispy crust because heat and air reach every side.

Filtration is another key use. Mesh screens filter juice, oil, and other liquids. They separate solids from liquids, making sure only the clean product goes forward. Mesh with a smooth surface is easy to clean, which keeps food safe and meets hygiene rules.

Sorting and grading are important in both farming and food processing. Vibrating mesh screens sort grains, nuts, or vegetables by size. This makes sure each package has the right mix and quality. Mesh comes in many sizes and patterns, so companies can pick what works best for their needs.

Here are some main ways woven wire mesh helps in agriculture and food processing:

- Allows crops to dry by letting air flow through while keeping pests out.

- Protects crops with strong, rust-resistant stainless steel.

- Lets sunlight reach plants for healthy growth.

- Filters juices and oils for clean, pure products.

- Moves food on conveyor belts for cooling, drying, or freezing.

- Sorts and grades produce by size for better quality.

- Provides baking trays that help food cook evenly.

- Cleans up easily, which keeps food safe.

A table below shows why woven wire mesh is a smart choice for these industries:

| Benefit | Why It Matters |

|---|---|

| Superior Filtration | Keeps food and drinks clean and pure |

| Durability | Lasts a long time, even with heavy use |

| Customizability | Fits many jobs with different mesh patterns |

| Easy Cleaning | Helps meet strict hygiene standards |

Tip: Companies like ANPENG offer woven wire screens that fit many jobs in farming and food processing. Picking the right mesh helps keep food safe and crops healthy.

How to Specify and Order Woven Wire Mesh

Assessing Application Needs

Every project starts with a clear goal. People need to know what the mesh will do before they choose a type. Some want to filter liquids. Others need to sort rocks or protect machines. Each job has its own needs.

Here are some questions to help with the first step:

- What will the mesh filter, screen, or protect?

- Will the mesh face high heat, chemicals, or water?

- Does the mesh need to be flexible or very strong?

- How small or large are the particles to be filtered or sorted?

- Will the mesh be used indoors or outdoors?

People who work with ANPENG often look at these questions before they specify and order woven wire mesh. This helps them pick the right product, like Woven Wire Screens for mining or Self-Cleaning Screens for sticky materials.

Tip: Write down all the details about the job. This makes it easier to talk with the mesh supplier.

Choosing Weave Type

The weave type changes how the mesh works. Each weave has its own strengths. Some are better for heavy loads. Others are best for fine filtering.

Key things to check:

- Mesh count: This means how many wires are in one inch. A higher mesh count means smaller openings.

- Opening size: This is the space between the wires. It decides what can pass through.

- Open area percentage: This shows how much of the mesh is open. More open area means better flow for air or liquid.

- Weave style: Plain weave is good for general jobs. Lock crimp is strong and stable. Dutch weave is best for fine filtering.

People measure mesh count in different ways for square and Dutch weaves. For example, square mesh counts the wires in both directions. Dutch weave counts only the warp wires. Open area is important for flow. If someone needs fast flow, they pick a mesh with a high open area percentage.

A table can help compare:

| Weave Type | Best For | Mesh Count | Open Area |

|---|---|---|---|

| Plain Weave | General screening | Medium | High |

| Lock Crimp | Heavy loads, stability | Low-Medium | Medium |

| Dutch Weave | Fine filtration | High | Low |

Note: Always match the weave type to the job. This helps the mesh last longer and work better.

Selecting Material

Material choice matters for how long the mesh lasts. Some materials fight rust. Others handle heat or look nice.

Common options:

- Stainless steel: Does not rust. Works well in wet or chemical places. Good for food, mining, and marine jobs.

- Galvanized steel: Costs less. Has a zinc coat to stop rust. Good for outdoor fences and cages.

- Brass and bronze: Look good and do not rust. Brass also carries electricity. Used for decoration and special filters.

- Specialty metals (like nickel or titanium): Handle high heat and strong chemicals. Used in labs, power plants, and the sea.

People should think about where the mesh will go. For example, stainless steel is best for salty or wet places. Brass or bronze works for art or design. Nickel and titanium are for tough jobs.

Tip: Tell the supplier about the work site. This helps them suggest the best material.

Ordering Tips

Ordering woven wire mesh can feel tricky, but a few smart steps make the process smooth. Buyers who follow these tips get the right mesh for their job and avoid costly mistakes.

1. Prepare a Clear Checklist

A checklist helps buyers organize their needs before talking to a supplier like ANPENG. Here’s a simple one:

- What is the main use? (screening, filtering, protection)

- What size and shape does the mesh need?

- Which weave type works best? (plain, lock crimp, Dutch, etc.)

- What material fits the job? (stainless steel, galvanized, brass, etc.)

- How much mesh is needed? (length, width, quantity)

- Any special features? (self-cleaning, PU-mesh, urethane panels)

2. Use Simple, Direct Language

Clear words help suppliers understand the order. Buyers should avoid technical jargon if they are not sure. For example, say “stainless steel plain weave, 10 mesh, 2mm wire, 1m x 5m rolls” instead of long, confusing sentences.

3. Share Application Details

Suppliers like ANPENG can give better advice when they know how the mesh will be used. Buyers should tell the supplier if the mesh will face high heat, chemicals, or heavy loads. They should mention if they need special screens, like self-cleaning or rubber panels.

Tip: Pictures or drawings help a lot. If buyers have a sketch or photo, they should send it with the order.

4. Double-Check Measurements

Mistakes with size cause big problems. Buyers should measure twice and write down the numbers clearly. They should check if they need the mesh cut to size or if they will cut it themselves.

5. Ask for Samples or Advice

If buyers feel unsure, they can ask for a sample or a small test piece. ANPENG often sends samples to help customers pick the right mesh. Buyers can also ask for advice about which product fits best.

Sample Order Format

Here’s a simple table buyers can use when sending an order:

| Item | Details |

|---|---|

| Product | Woven Wire Screen |

| Weave Type | Lock Crimp |

| Material | Stainless Steel 304 |

| Mesh Count | 20 mesh |

| Wire Diameter | 1.2 mm |

| Panel Size | 1m x 2m |

| Quantity | 10 panels |

| Special Features | Self-cleaning, if possible |

| Application | Quarry screening |

Note: The more details buyers give, the faster and more accurate the order will be.

6. Confirm Lead Time and Delivery

Buyers should ask how long the order will take and how it will ship. They should check if the supplier can meet their project deadline.

7. Keep Communication Open

Good communication helps avoid mistakes. Buyers should reply quickly to questions from the supplier. They should keep all emails and order forms for reference.

By following these tips, buyers can order woven wire mesh with confidence. ANPENG’s team helps every step of the way, from picking the right screen to making sure it arrives on time.

Conclusion

Woven wire mesh comes in many types, weaves, and materials. Each one fits a different job, from filtration to safety. Choosing the right mesh helps projects run smoothly and last longer. ANPENG offers Woven Wire Screens, Self-Cleaning Screens, PU-Mesh Screens, Urethane Panels, and Rubber Panels & Punch Plates. Their team helps customers pick the best mesh for any need. Need advice or a custom solution? Contact ANPENG for expert support and reliable screening media.

FAQ

What is woven wire mesh used for?

Woven wire mesh helps with screening, filtering, and protecting. People use it in mining, construction, food processing, and factories. ANPENG’s wire screens work well for sorting rocks, filtering liquids, and keeping machines safe.

How do I choose the right mesh type?

Think about what you need the mesh to do. Check the size of particles, strength needed, and if it must resist rust. ANPENG offers plain, lock crimp, and self-cleaning screens for different jobs.

What materials are best for outdoor use?

Stainless steel and galvanized steel work best outside. Stainless steel resists rust and lasts longer. Galvanized steel costs less and works for fences or cages. ANPENG’s screens use both materials for outdoor jobs.

Can woven wire mesh handle high temperatures?

Yes, stainless steel and specialty alloys like nickel or titanium can take high heat. These materials keep their shape and strength in hot places. ANPENG’s woven wire screens work in furnaces and heat exchangers.

What is the difference between square mesh and filter cloth?

Square mesh has bigger, open holes for sorting larger items. Filter cloth has a tighter weave for fine filtration. ANPENG supplies both types for mining, food, and chemical industries.

How do I order custom mesh from ANPENG?

Write down your needs: mesh type, size, material, and use. Share drawings or photos if possible. ANPENG’s team helps pick the right screen and gives advice on special features like self-cleaning or urethane panels.

Are self-cleaning screens better for sticky materials?

Yes! Self-cleaning screens stop clogging and keep material moving. They work well for wet or sticky jobs, like in mining or food processing. ANPENG’s self-cleaning screens save time and reduce downtime.

Can I get samples before placing a big order?

Absolutely. ANPENG offers samples so you can test the mesh first. This helps make sure you get the right product for your job.