A single deck vibrating screen has one screen layer. It also has two discharge outlets. It separates materials by their size. You use this type of vibrating screen when you need to sort things fast. It works well because it uses mechanical vibration. If you know how the vibrating screen works, you can get better results. This is true if you work in mining, construction, recycling, or food processing. The screening media you pick can make your screen work better. You can choose woven wire mesh, self-cleaning screens, or PU-mesh.

Here are some places where you will see single deck vibrating screens:

| Industry | Application Purpose |

|---|---|

| Mining | Size separation and dewatering for mineral processing |

| Construction | Grading and separating aggregates |

| Recycling | Sorting metals, plastics, and glass |

| Food and Beverage | Product sorting for quality control |

| Chemical | Particle size and purity control |

Key Takeaways

- A single deck vibrating screen has one layer. It has two outlets for material to come out. This helps separate materials well.

- Pick the right mesh type for your material. Think about the size and moisture of your material. This helps the screen work better.

- You need to do regular maintenance. Check if the mesh is damaged. Clean any blockages to keep the screen working well.

- The angle of the screen frame changes how fast sorting happens. It also changes how accurate sorting is. Adjust the angle to get the best results for you.

- Single deck screens use less energy. This makes them cheaper to use for a long time. Many industries use them because of this.

- Use self-cleaning or PU-mesh screens for wet or sticky stuff. This stops clogging and keeps things moving.

- Single deck vibrating screens can be used in many ways. They help sort things fast in mining, construction, recycling, and food processing.

- Use dust and noise control to make work safer. This also makes the workspace more comfortable.

Single Deck Vibrating Screen Overview

Definition and Function

A single deck vibrating screen is not like other screens. It has only one layer to sort materials by size. There are two discharge outlets on this screen. Fine material goes through the mesh and leaves from one outlet. Bigger pieces stay on top and leave from the other outlet. This screen is good when you need to sort things quickly and accurately. It works best with dry materials that have a certain amount of moisture. The design is simple, so it uses very little energy. Maintenance is fast and easy because of this.

When you look at single deck vibrating screens and compare them to others, you see some big changes:

| Feature | Single Deck Vibrating Screen | Other Types of Vibrating Screens |

|---|---|---|

| Screen Frame | Single deck frame | Multiple deck frames |

| Discharge Ports | Usually two discharge ports | Can have many discharge ports |

| Sifting Sequence | High precision from top to bottom | Depends on design |

| Material Suitability | Best for dry materials with specific moisture | Handles more types, even sticky ones |

| Energy Consumption | Very low | Often higher |

| Maintenance | Fast and easy | More complex |

| Applications | Fine powder screening in many industries | Broader, depends on type |

People use single deck vibrating screens in mining, construction, recycling, and food processing. These screens help you separate materials fast and with great accuracy.

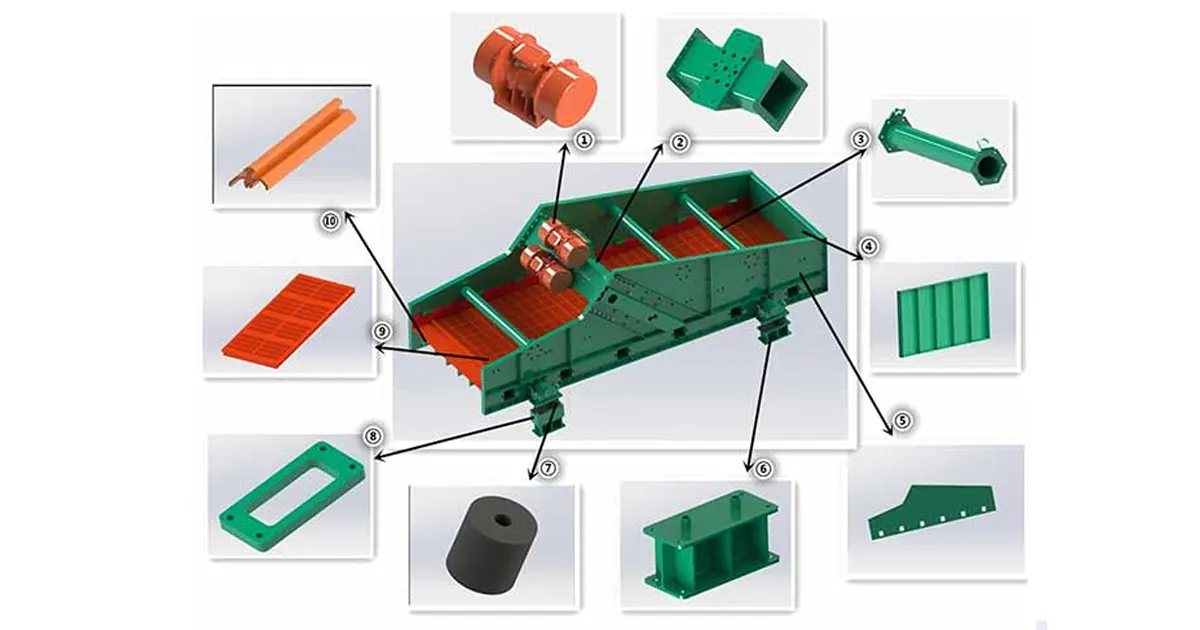

Basic Structure

A single deck vibrating screen is built strong but simple. It has a few main parts that work together to make sorting easy.

Screen Frame

The screen frame keeps the mesh in place. It is strong and holds up the weight of the material. The frame also supports the shaking motion. You can find frames made from steel or other hard materials. The design lets you change the mesh quickly when needed.

Discharge Outlets

Most single deck vibrating screens have two discharge outlets. Fine material falls through the mesh and goes out one outlet. Bigger pieces stay on top and go out the other outlet. This way, you can sort materials into two groups at once. It saves time and keeps things simple.

Here’s a quick look at the main parts and what they do:

| Component | Contribution |

|---|---|

| Screen Body | Holds the mesh and keeps the whole thing strong. |

| Screen Mesh | Sorts materials by size. You can pick the mesh you need. |

| Vibration Mechanism | Makes the screen shake so materials move and separate. |

| Drive Motor | Gives power to the vibration and keeps the screen working. |

| Springs and Suspensions | Take in the shaking and keep the screen steady. |

| Supporting Structure | Makes the screen stable and stops it from wobbling. |

| Clamp Rings and Seals | Hold the mesh tight and keep dust inside. |

| Dust Enclosures and Covers | Trap dust so your workspace stays clean. |

| Isolation Springs and Bearings | Lower friction and help the screen last longer. |

| Drive Belt and Pulleys | Move power from the motor to the vibration part (if used). |

The simple design makes it easy to take care of the screen. You can change parts quickly and keep your sorting job going well.

Vibrating Screen Working Principle

Vibration Mechanism

When you use a single deck vibrating screen, the important part is the vibration mechanism. There are different types of vibration. Each type helps separate materials in a special way. The motor, exciter, or eccentric shaft makes the screen shake. This shaking keeps materials moving and bouncing on the mesh. You can see how each vibration type works in the table below:

| Type of Vibration | Description | Advantages |

|---|---|---|

| Circular Vibration | Eccentric weights create circular motion. | Best for coarse screening with high conveyance speed. |

| Linear Vibration | Twin counter-rotating motors create straight-line oscillation. | Ideal for fine screening with better particle stratification. |

| Elliptical Vibration | Hybrid motion adjusts based on deck position. | Effective for sticky or wet materials. |

| High-Frequency Vibration | Electromagnetic or ultrasonic vibrators. | Prevents blinding of mesh for ultra-fine powders. |

You pick the vibration type that fits your needs. Circular vibration is good for moving big pieces fast. Linear vibration is better for sorting small pieces. Elliptical vibration works well for sticky or wet stuff. High-frequency vibration keeps the mesh clean for very fine powders.

Tip: To make your screen work better, choose the vibration mechanism that matches your material separation goal.

Inclined Frame Operation

The angle of the frame is very important for how your vibrating screen works. When you tilt the frame, materials move faster across the mesh. The right angle helps you balance speed and how well you separate things. If you use a steep angle, materials move fast, but sorting may not be as accurate. A gentle angle slows things down and gives you better sorting.

Check out this table to see how the angle changes your results:

| Inclined Angle (°) | Flow Rate/Flux (m/min) | Efficiency (%) |

|---|---|---|

| 18 | 18.29 | 86.4 |

| 20 | 24.39 | 54.6 |

| 22 | 30.48 | 62.8 |

| 25 | 36.58 | 64.2 |

| 30 | 32.37 | 67.5 |

A lower angle gives you better sorting. A higher angle makes things move faster. You need to find the best angle for your job. If you want better sorting, use a lower angle. If you want more speed, use a higher angle.

Material Separation Process

Let’s look at how the vibrating screen helps you sort materials by size. The vibration keeps everything moving. Small pieces fall through the mesh holes. Big pieces stay on top and move to the discharge outlet. Here’s how it works step by step:

- The vibration keeps materials moving.

- Small particles fall through the mesh holes.

- Large particles move to the discharge outlet because they are too big for the holes.

This process makes your work smooth and fast. The shaking stops fine particles from sticking together. You get clean and accurate sorting every time. If you want better results, set your vibrating screen for the right vibration and angle.

Note: The vibrating screen working principle uses motion and mesh size to sort materials quickly and accurately. You control how it works by changing the vibration type and the frame angle.

You can use vibrating screens for many kinds of materials. It works for dry rocks, sticky minerals, or very fine powders. The right setup helps you get the best results. The single deck vibrating screen makes sorting easy, fast, and reliable.

Vibrating Screen Design and Components

When you look at a single deck vibrating screen, you see more than just a shaking box. The design of each part matters. If you want the best screening results, you need to know how each component works together. Let’s break down the main parts and see how they boost screen capacity and vibrating screen capacity.

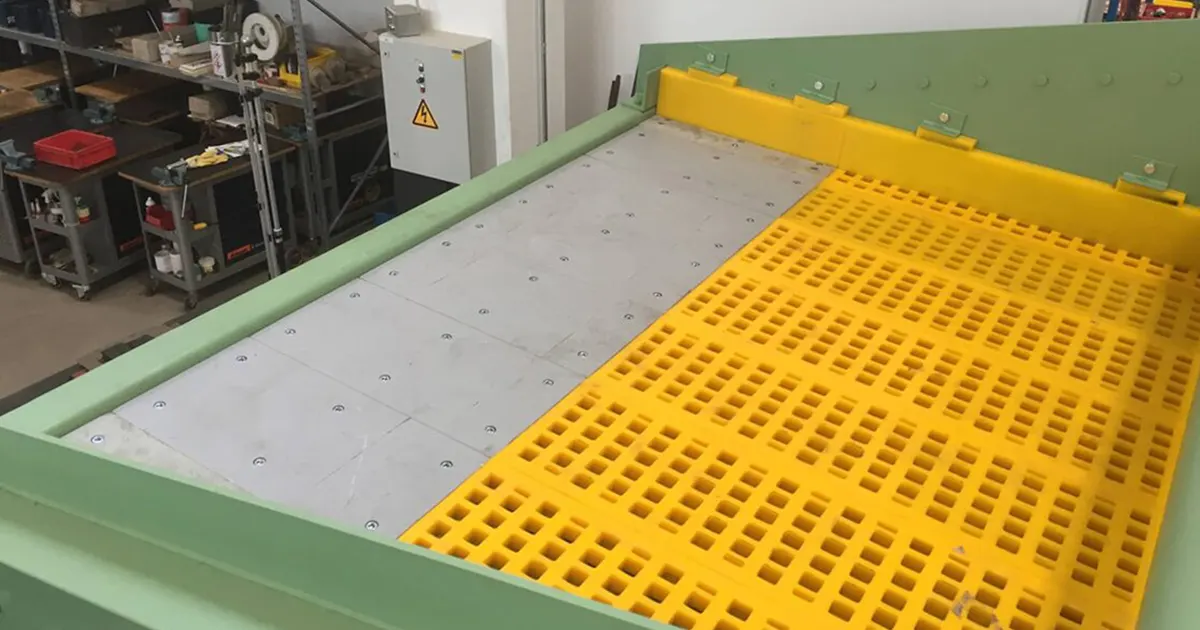

Screen Mesh Options

You have a few choices when it comes to the mesh on your screen deck. Each type of mesh changes how your vibrating screen works and how much material you can process.

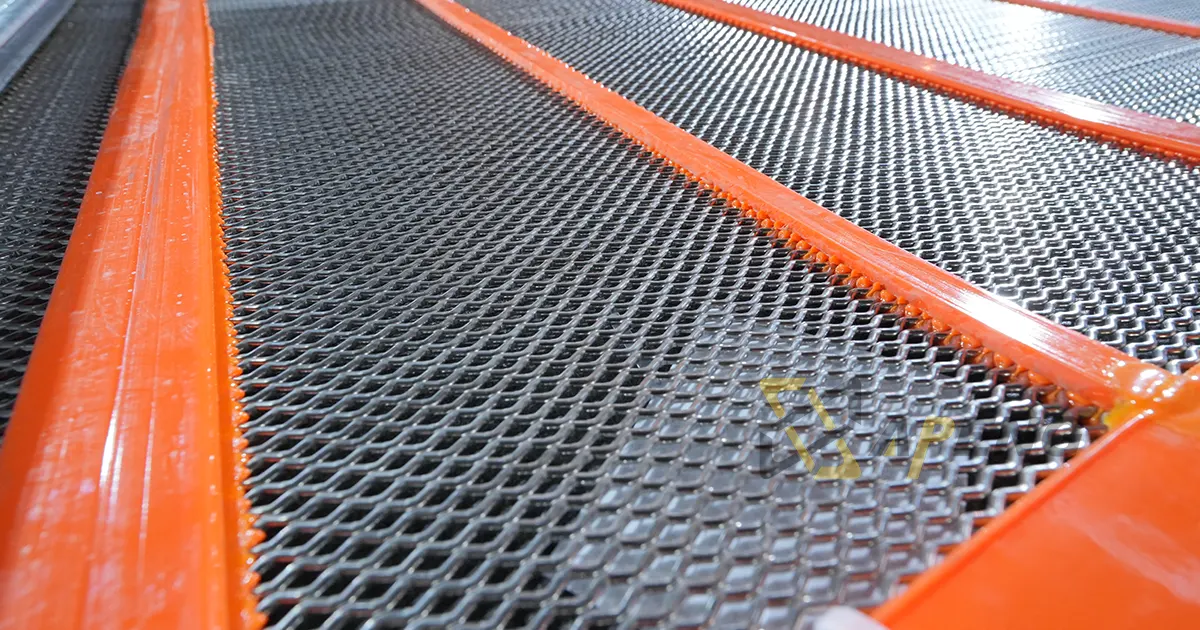

Woven Wire Mesh

Woven wire mesh is a classic choice. You get strong wires woven together to make a grid. This mesh gives you high accuracy for screening. You can use it for many materials. It’s easy to clean and replace. If you want a balance between cost and performance, this mesh works well.

Self-Cleaning Screens

Self-cleaning screens help you when materials tend to clog. These screens use special wires or shapes that move and flex. This action shakes off sticky stuff. You don’t have to stop your vibrating screen as often to clean it. That means you keep your screen capacity high and your screening process smooth.

PU-Mesh Screens

PU-mesh screens use polyurethane. This material is tough and resists wear. You can use these screens for abrasive or wet materials. They last longer than wire mesh. You also get less noise and less blinding. If you want a quiet and steady screening job, PU-mesh screens are a smart pick.

Tip: The mesh material you choose affects your vibrating screen capacity and how often you need to do maintenance.

Here’s a quick look at common mesh materials and their features:

| Material | Characteristics |

|---|---|

| Stainless Steel | Durable, corrosion-resistant (e.g., SS304, SS316) |

| Polyurethane | Resistant to clogging and wear |

| Manganese Steel | High tensile strength for heavy-duty use |

Deck Size and Configuration

The size and setup of your screen deck play a big role in how much you can process. If you use a larger screen, you can handle more material at once. That means higher screen capacity and vibrating screen capacity. Smaller mesh sizes give you better accuracy, but they slow down the flow. Wider screens carry more material, but you need to match them to your material flow. Longer screens give fine particles more time to separate, but they take up more space.

Here’s how different aspects of deck design impact your results:

| Aspect | Impact on Throughput and Efficiency |

|---|---|

| Screen Size | Larger screens handle higher capacity, improving throughput. |

| Mesh Size | Smaller meshes increase accuracy but reduce throughput; larger meshes allow more material but may lower precision. |

| Number of Decks | Single decks are suitable for simple tasks; multiple decks enhance separation capabilities in one pass. |

| Screen Width | Wider screens can carry more material but may reduce efficiency if not matched to material flow. |

| Screen Length | Longer screens improve separation efficiency for fine particles but require more space and energy. |

You need to pick the right design for your job. If you want more screen capacity, go for a bigger screen deck. If you want better accuracy, use a smaller mesh. Always think about your space and energy needs.

Motor and Drive System

The motor and drive system give your vibrating screen its power. You need a strong motor to keep the screen deck moving. The drive system can use belts, gears, or direct drive. Each setup changes how the screen shakes and how much material you can process. If you want steady screening, keep your motor in good shape. A well-designed drive system means you get the most out of your vibrating screen design.

Note: The right motor and drive system boost your vibrating screen capacity and keep your screening process running without stops.

When you put all these parts together, you get a single deck vibrating screen that fits your needs. The design of the mesh, deck, and motor all work to give you the best screen capacity and screening results.

Screening Media Types

Woven Wire Mesh

You see woven wire mesh in many vibrating screens. This type uses wires woven together to form a grid. You get a flexible screen that fits odd shapes and comes in many sizes and thicknesses. Woven wire mesh costs less because it needs less labor to make. You can swap it out quickly when you need a new one. If you want a screen that works for lots of different materials, this is a solid choice.

- Costs less due to less labor involved

- Flexible for odd shapes

- Available in various sizes and thicknesses

Here’s a quick look at how woven wire mesh compares to other types:

| Type of Mesh | Advantages | Disadvantages |

|---|---|---|

| Woven Wire Mesh | Costs less, flexible, many sizes available | Not as strong as welded metal, small particles may fall through holes |

You get good screening efficiency with woven wire mesh, but it may wear out faster than other types. If you need a screen for short-term jobs or want to save money, this type works well.

PU-Mesh Screens

PU-mesh screens use polyurethane, which is tough and lasts a long time. You find these screens in mining and heavy-duty jobs. They resist wear much better than steel or rubber. You get more throughput and a longer lifespan. PU-mesh screens absorb more impact energy, so they handle rough materials without breaking down.

| Feature | PU Screens | Rubber Screens | Steel Woven Mesh |

|---|---|---|---|

| Lifespan | 12-18 months | 3-4 months | 1.5-2.5 months |

| Wear Resistance | 3 times better than steel | Less durable | Standard durability |

| Impact Energy Absorption | 40% more than steel | Lower absorption | Standard absorption |

| Throughput | 380-425 tons/hour | 290-320 tons/hour | Standard throughput |

| Open Area | 25-40% more than steel | Standard open area | Standard open area |

| Stability | ±0.1 mm after 5,000 hours | Less stable | Less stable |

You get better wear resistance and more stable performance with PU-mesh screens. If you want less downtime and higher screening efficiency, this type is a smart pick. Regular inspection helps you keep your screen working at its best.

Self-Cleaning Screens

Self-cleaning screens solve problems like blinding and clogging. You see these screens use crimped wires that vibrate on their own. This keeps material from sticking and lets you process more without stopping. You get higher throughput and better open area than woven wire mesh. These screens work well when you deal with sticky or wet materials.

| Type of Mesh | Advantages | Disadvantages |

|---|---|---|

| Self-Cleaning Screens | Reduces blinding, higher throughput, better open area | Initial engineering may require more investment |

Self-cleaning screens help you keep your vibrating screen running smoothly. You spend less time cleaning and more time screening. If you want to boost your product quality and efficiency, consider this type for your next job.

Tip: The screening media you choose affects how well your vibrating screens work. Pick the right type for your material and job needs.

Urethane Panels

If you want something strong for your vibrating screen, try urethane panels. These panels are made from a special plastic called polyurethane. This material is tough and bends without breaking. It can handle heavy jobs and rough materials.

Many people pick urethane panels for good reasons:

- Urethane panels last a long time. They do not wear out fast, even with all-day use.

- They do not get cut or torn easily. Sharp rocks or metal will not break them.

- They make less noise. Urethane panels soak up sound, so your work area is quieter.

- Cleaning is easy. Stuff does not stick to the panels, so you spend less time cleaning.

Let’s see how urethane panels stack up against other screen types:

| Feature | Urethane Panels | Woven Wire Mesh | PU-Mesh Screens | Self-Cleaning Screens |

|---|---|---|---|---|

| Wear Resistance | Excellent | Good | Excellent | Good |

| Noise Reduction | High | Low | High | Medium |

| Maintenance | Low | Medium | Low | Low |

| Cost | Medium | Low | Medium | Medium |

| Open Area | Medium | High | Medium | High |

You can use urethane panels in many places. Mining, quarrying, and recycling all use these panels. They are good for sorting big rocks, sand, or glass. Urethane panels fit most vibrating screens, so you do not need a new one.

Here are some tips to help your urethane panels last longer:

Tip: Look at your panels often for damage. Change any broken panels right away. This keeps your vibrating screen working well and stops bigger problems.

You can pick different shapes and sizes for your urethane panels. Some have small holes for tiny pieces. Others have big holes for large pieces. Choose the panel that fits your material and job.

If you want a screen that lasts, is quiet, and easy to care for, urethane panels are a smart pick. They help your vibrating screen work better and make your job easier.

Mesh Selection for Screening

Choosing the right mesh for your vibrating screen can make your job much easier. You want to get the best results and avoid problems like clogging or high costs. Let’s look at what you need to think about before you pick a mesh.

Material Properties

Moisture and Stickiness

Wet or sticky materials can cause headaches. They often block the mesh and slow down your work. Here’s what you should keep in mind:

- Wet or sticky materials can clog the mesh openings.

- For these materials, use a coarser mesh or one with an anti-blinding design. Polyurethane screens work well here.

- If you pick the wrong mesh, you might see low efficiency and more downtime.

Tip: If you deal with sticky or wet materials, always choose a mesh that fights clogging. This keeps your screening process smooth.

Particle Size

The size of the particles you want to separate matters a lot. You need to match the mesh size to your material. If you use a mesh that is too fine, you might need more pressure, and the screen could clog. If you use a mesh that is too coarse, you might not catch all the small pieces. Think about the type and amount of particles you want to remove. Hard or soft particles and the level of contamination also play a role. The right mesh size helps you get the best filtration and keeps your process running well.

Application Environment

Mining and Quarry

In mining and quarry jobs, you often deal with heavy, rough materials. You need a mesh that can handle tough conditions. Strong wire mesh or polyurethane panels work well. They last longer and keep your screening process going without many stops.

Aggregate and Recycling

For aggregate and recycling, you might see a mix of dry and wet materials. You want a mesh that can handle both. Self-cleaning screens or urethane panels are good choices. They help you avoid blockages and keep your operation efficient.

| Application | Recommended Mesh Type | Why It Works Well |

|---|---|---|

| Mining & Quarry | Polyurethane, Wire Mesh | Handles heavy loads, resists wear |

| Aggregate/Recycling | Self-cleaning, Urethane | Prevents clogging, easy to clean |

Durability and Maintenance

You want your mesh to last as long as possible. Durable mesh means less time spent on repairs and lower costs. Advanced mesh designs help materials flow better and boost recovery rates. High-quality wire mesh gives you more flexibility and meets industry standards. If you pick a durable, low-maintenance mesh, you save money over time and keep your screening process running strong.

Note: Check your mesh often for damage. Replace worn parts quickly to avoid bigger problems.

By thinking about your material, environment, and how long you want your mesh to last, you can make the best choice for your screening needs.

Single Deck Vibrating Screen Benefits

Screening Efficiency

You want your screening process to be fast and accurate. A single deck vibrating screen gives you reliable results for many jobs. You get a simple setup that works well for most materials. The high screening efficiency helps you separate particles by size without much trouble.

Let’s look at how it compares to other screens:

- A double-deck vibrating screen can reach about 61.9% efficiency.

- A single deck vibrating screen usually gets around 56.7% efficiency.

- Multi-deck screens work better for complex mixes of particle sizes.

If you handle basic sorting tasks, a single deck vibrating screen is a smart choice. You get good results with less equipment. For more complex jobs, you might need a multi-deck screen. Still, for most day-to-day screening, you will find the single deck option does the job well.

Tip: If you want to boost your high screening efficiency, keep your mesh clean and check for blockages often.

Energy Use

You care about energy costs. Single deck vibrating screens use very little energy. They work well for assembly lines and long shifts. You save money because the motors do not have to work as hard as with other types of equipment.

Here’s what you need to know:

- These screens use less power than other screening machines.

- If your screen gets blocked or clogged, the motor uses more energy.

- Keeping your screen clean helps you save on utility bills.

When you use a single deck vibrating screen, you get both high efficiency and low energy use. This makes your operation more sustainable and cost-effective.

Maintenance

You want your equipment to last. Regular maintenance keeps your vibrating screens running smoothly. Most problems are easy to spot and fix if you check your screen often. Here’s a quick guide to common issues and how to solve them:

| Maintenance Challenge | Description | Solution |

|---|---|---|

| Faults in the screening mesh | Mesh damage can cause overload and wear. | Inspect and repair mesh regularly. |

| Faults in springs | Broken springs cause unbalanced movement. | Check and adjust springs often. |

| Motor or transmission faults | Broken belts or bearings stop the screen. | Replace faulty parts right away. |

| Faults in unbalance exciters | Worn gears or bearings cause failures. | Monitor and fix as needed. |

| Cracking of the screen body | Cracks form under stress. | Inspect and reinforce weak spots. |

| Loose bolts and fasteners | Loose parts cause poor vibration. | Tighten bolts and use lock nuts. |

| Screen blinding and blockage | Blockages lower screening efficiency. | Clean the screen and use anti-blinding tools. |

| Inadequate vibration | Weak vibration hurts performance. | Maintain motors and weights. |

You can keep your vibrating screen in top shape with simple checks and quick fixes. This means less downtime and more productivity for you.

Dust and Noise Control

You want your workspace to stay clean and quiet, right? Single deck vibrating screens can kick up a lot of dust and make plenty of noise. If you do not control these, you might face health risks and unhappy workers. You also want to keep your equipment running well and your screening efficiency high.

Let’s talk about dust first. When you pour material onto the screen, fine particles can float into the air. You do not want to breathe that in. Here are some ways you can keep dust under control:

- Use dust collection systems. Cyclone dust collectors pull dust out of the air and trap it in a safe place.

- Wet scrubbers spray a fine mist that catches dust and brings it down. This keeps the air clear.

- Enclose the screen with covers or hoods. This stops dust from escaping into your workspace.

Noise is another big problem. Vibrating screens can get loud, especially in busy plants. Too much noise can hurt your ears and make it hard to talk. You can lower the noise with these tricks:

- Run your screen at the best settings. When you operate equipment under optimal conditions, you get less noise.

- Use internal polymers inside the machine. These materials soak up sound and make the screen quieter.

- Seal the outside with polymer panels. This can cut noise by 5 to 10 decibels. That is a big drop!

- Build noise reduction walls or enclosures around the screen. These can lower noise by 10 to 15 decibels. Your ears will thank you.

Tip: Check your dust and noise controls often. Clean dust collectors and look for worn-out seals. If you keep up with these tasks, you make your workspace safer and more comfortable.

You do not have to choose between a clean, quiet plant and good screening. With the right dust and noise control, you can protect your team and boost your efficiency at the same time.

Screening Applications

Mining

You see single deck vibrating screens used everywhere in mining. These machines help you sort and process materials fast. You can use them for many jobs in a mine. Here’s how you might use a vibrating screen in your mining operation:

- Sizing and classification: You separate ore into different sizes. This helps you feed the right size to the next piece of equipment.

- Dewatering: You remove extra water from slurries. This makes handling easier and keeps your process clean.

- Scalping: You get rid of oversized rocks before they reach the primary crusher. This step protects your machines and boosts efficiency.

- Washing: You clean materials to remove dirt and improve quality.

When you use a vibrating screen in mining, you get better results and less downtime. You keep your process smooth and your equipment safe.

Quarry

If you work in a quarry, you know how important sorting is. You want to get the right size of gravel, sand, or crushed stone. A single deck vibrating screen helps you do this job well. You can use two main types of screens in a quarry:

- Inclined screens: These sit at an angle, usually between 5 and 45 degrees. Gravity and vibration work together to move material and sort it fast. Inclined screens are great for high-capacity jobs and coarse aggregates.

- Horizontal screens: These lay flat or have a small slope. They give you precise size separation. You use them for fine aggregates.

You need to think about many factors when you pick a screen for your quarry. Here’s a table to help you see what matters:

| Factor | Description |

|---|---|

| Basic capacity | How much material can pass through the screen. |

| Incline | The angle needed for good screening. |

| Deck | How much of the deck you can use based on material flow. |

| Oversize | The amount of material that stays on top of the screen. |

| Half size | The percent of material half the size of the opening. |

| Slot | The size of the openings in the screen. |

| Condition | The state of the feed and the environment. |

| Shape | The shape of the particles. |

| Weight | The density of the material. |

| Open area | How much open space the screen has for material to pass through. |

You use vibrating screens in a quarry to sort materials, improve quality, and protect your other machines.

Aggregate

You use vibrating screens in aggregate plants every day. These screens help you sort and clean materials like sand, gravel, and crushed stone. You want your final product to meet strict standards. A single deck vibrating screen gives you the control you need for each application.

- You can sort core materials by size. This helps you get the right mix for concrete, asphalt, or road base.

- You improve material quality. Clean, sorted aggregates make your projects stronger and last longer.

- You protect your downstream equipment. Removing oversized pieces keeps crushers and conveyors safe.

You can pick inclined screens for big jobs or horizontal screens for fine sorting. Each type helps you boost efficiency and get the best results for your application.

Tip: Check your screen often. Clean it and fix any problems right away. This keeps your screening process running smoothly and saves you time.

Construction and Recycling

You find single deck vibrating screens in many construction and recycling sites. These machines help you sort and clean materials before using them or sending them away. In construction, you want your sand, gravel, and crushed rock to meet rules. In recycling, you need to quickly separate metals, plastics, paper, and glass.

Let’s start with construction. You use vibrating screens to group materials by size. Fine sand is for concrete. Medium gravel is for roads. Large rocks are for drains. The screen helps you get the right mix for each job. You save time because you do not sort by hand. You also make your final product better.

Here is how single deck vibrating screens help in construction:

- Sort sand, gravel, and crushed rock by size

- Take out unwanted pieces from aggregates

- Get materials ready for concrete, asphalt, or road work

- Make every batch more even and better quality

You get cleaner and more reliable building materials. Your projects finish on time. You avoid mistakes that cost money.

Now let’s talk about recycling. You want to recover as much as you can. Vibrating screens make this simple. You put mixed waste on the screen. The machine shakes and sorts metals, plastics, paper, and glass. Each type goes out a different outlet. You recycle more and send less to the dump.

Here is what vibrating screens do in recycling:

- Separate metals, plastics, paper, and glass

- Remove dirt and small trash from recyclables

- Make sorting faster and more correct

- Help you reach recycling goals and cut down waste

Tip: For better results, check your screen often. Clean it and change old mesh. This keeps sorting fast and smooth.

You can see how single deck vibrating screens make work easier. You get better materials for building. You recover more in recycling. You save time and money every batch.

Here is a table that shows how these screens help both industries:

| Industry | Main Screening Tasks | Benefits |

|---|---|---|

| Construction | Sort sand, gravel, crushed rock | Better quality, less waste |

| Recycling | Separate metals, plastics, glass | Higher recovery, faster sorting |

You do not need fancy machines to get good results. A single deck vibrating screen lets you sort, clean, and get materials ready for any job. You keep your work going well and help the environment too.

Conclusion

If you want the best results from your vibrating screen, you need to know how it works and pick the right mesh. Here’s what matters most:

- You boost efficiency when you understand how vibration helps with screening.

- The mesh you choose should match your material’s size, shape, and moisture.

- The right screen media—like woven wire mesh, self-cleaning screens, or PU-mesh—makes your job easier.

You can trust ANPENG for quality vibrating screens. They offer fast delivery, custom options, and great value for your screening needs.

FAQ

What is a single deck vibrating screen?

You use a single deck vibrating screen to separate materials by size. It has one screen layer and two outlets. Fine pieces fall through the mesh. Larger pieces move off the top.

How do you choose the right mesh for your material?

Think about your material’s size, shape, and moisture. Sticky or wet materials need self-cleaning or PU-mesh. Dry, regular materials work well with woven wire mesh.

Tip: Always match mesh size to your smallest particle for best results.

How often should you check your vibrating screen?

Check your screen every day if you use it a lot. Look for tears, blockages, or loose parts. Quick checks help you avoid big problems later.

Can you use a single deck vibrating screen for wet materials?

Yes, you can. Use self-cleaning screens or PU-mesh for wet or sticky materials. These options help prevent clogging and keep your process smooth.

What industries use single deck vibrating screens?

You see these screens in mining, construction, recycling, food, and chemical plants. They help you sort, clean, and prepare materials for the next step.

| Industry | Common Use |

|---|---|

| Mining | Ore sizing |

| Construction | Aggregate sorting |

| Recycling | Material separation |

| Food | Product grading |

How do you reduce noise and dust from your vibrating screen?

You can add covers, dust collectors, or polymer panels. These steps keep your workspace cleaner and quieter. Regular cleaning also helps control dust.

What is the main benefit of a single deck vibrating screen?

You get simple operation and easy maintenance. It works fast and uses little energy. You can sort materials quickly and keep your process moving.