You’ll find screen mesh in a variety of industries and applications. From factories to construction sites, screen mesh plays a vital role in sorting, separating, and filtering materials. Whether you’re working with gravel, minerals, or waste, the right screen mesh ensures optimal performance. There are many types of screen mesh, each designed for specific tasks. Some common types include woven wire mesh, polyurethane screens, and self-cleaning screens, all of which provide unique benefits depending on your needs. For example, woven wire mesh offers high durability and precision, while polyurethane screens are ideal for harsh, abrasive environments.

Here are some types of screen mesh you might encounter:

- Woven Wire Cloth

- Polyurethane Screens

- Rubber Screens

- Perforated Plate Screens

Each type of screen mesh is crafted to perform effectively in different industrial applications, ensuring maximum efficiency and longevity.

Key Takeaways

- Screen mesh has different types. These include woven wire, polyurethane, and self-cleaning screens. Each type is made for a special job.

- Mesh size and aperture are very important. They decide what can go through the mesh. They also change how well the screen works.

- Woven wire mesh is useful and not expensive. It works for many things, like mining or home use.

- Self-cleaning screens stop clogs from happening. This means less time fixing them. They are good for wet or sticky stuff.

- Polyurethane screens last a long time. They do not wear out easily. They are best for tough places and heavy jobs.

- When you pick a screen mesh, think about the material and mesh size. Also, think about what your project needs. This helps the screen work its best.

- Cleaning and taking care of screens often helps them last longer. It also makes them work better. You will not need to replace them as much.

Screen Mesh Overview

What Is Screen Mesh

You might wonder what screen mesh actually means. In simple terms, it’s a material made of woven or welded wires that forms a grid. You see these grids in many places, from factories to your own windows. People use them to separate, protect, or filter things. In industry, screens play a big role in sorting materials by size. You can find them in mining, construction, and even food processing.

Here’s a quick look at how experts define screen mesh in industry:

| Definition/Specification | Description |

|---|---|

| ASTM E 2016 | Current industry standard for woven wire mesh covering terminology, tolerances, and inspection criteria. |

| ISO 9044 | International standard for woven wire mesh applicable to particle separation and screening applications. |

You’ll also see screens used for fencing, display, and protection. When you look at a woven wire mesh overscreen, you’ll notice it’s carefully crafted and labeled with its mesh size. This helps workers pick the right one for the job.

Mesh Size and Aperture

Mesh size and aperture are two important words you’ll hear when talking about screens. Mesh size tells you how many openings there are in one inch of the mesh. Aperture means the size of each opening. Both of these affect how well screens can separate materials.

- Mesh size and aperture control what passes through and what stays out.

- The shape and size of the particles matter. Some particles fit through easily, while others get stuck.

- The way you feed material onto the screens, and how fast you do it, can change the results.

- Vibrations help move particles across the mesh, making the process faster and more efficient.

If you want to see how particles behave on screens, engineers use computer models. These models show how different shapes and sizes of openings affect the screening process.

Tip: Always check the mesh size and aperture before choosing a screen for your project. This helps you get the best results.

Role in Industrial Screening

You use screens in many industries because they help you separate materials quickly and accurately. In mining, screens let you pull valuable ore away from waste rock. In construction, you make sure sand and gravel are the right size for building strong roads and buildings. Food companies use screens to sift grains and filter liquids, keeping everything clean and safe.

Screen mesh does more than just sort things. It helps you control quality, improve safety, and save time. When you pick the right screens, your work gets easier and your results get better.

Types of Screen Mesh

When you look at the different types of screen mesh, you’ll see that each one has its own strengths. You might need a certain type for your project, so let’s break down the main types of screen mesh you’ll find in industry.

Woven Wire Mesh

Features

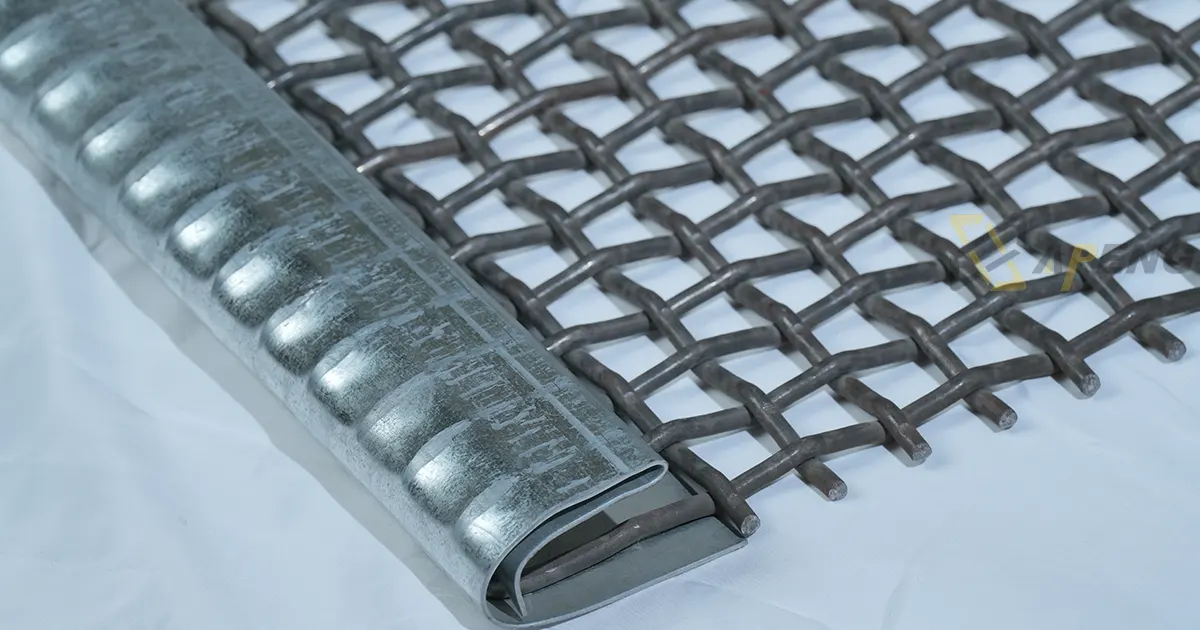

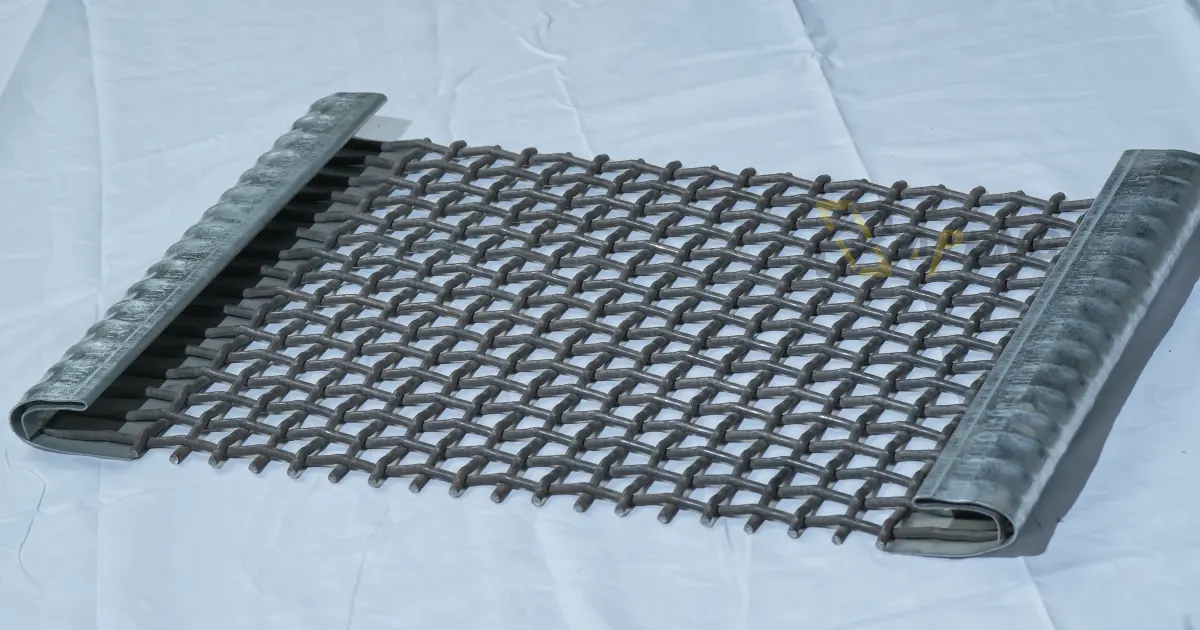

Woven wire mesh is one of the most popular types of screen mesh. You see it everywhere, from mining sites to your backyard. This mesh uses wires woven together to form a grid. You can choose from square hole woven mesh, long hole woven mesh, or double-wire braided mesh. Each one gives you a different opening shape and strength.

Here’s a quick table to help you compare the main types of woven wire mesh:

| Type of Mesh | Description | Advantages |

|---|---|---|

| Square Hole Woven Mesh | High-strength steel wire in a plain weave | Simple, low-cost, good wear resistance |

| Long Hole Woven Mesh | Rectangular grid for faster material flow | Larger opening, improved efficiency |

| Double-Wire Braided Mesh | Two wires for extra strength | Superior durability, excellent impact resistance |

You can pick from many materials for woven wire mesh. Some common choices are:

- Stainless steel screens: Great for wet or corrosive places.

- Aluminum screens: Lightweight and easy to handle.

- Brass and bronze: Good for decoration or special uses.

- Galvanized steel: Works well outdoors.

- Nickel and titanium: Handle heat and chemicals.

Woven wire mesh lasts a long time. You can expect it to work for 15 to 30 years if you take care of it. Make sure you install it right and check it often. Clean it when needed to keep it working well.

Industrial Uses

You’ll find woven wire mesh in many industries. Mining companies use it to sort rocks and minerals. Construction crews use it to separate sand and gravel. Recycling plants use it to filter out unwanted pieces. You can even see it in food factories, where it helps sift grains or sugar.

If you need a tough and flexible screen, woven wire mesh is a smart choice. It handles heavy loads and keeps working even in rough conditions. You can trust it for many types of screen mesh jobs.

Self-Cleaning Screens

Design

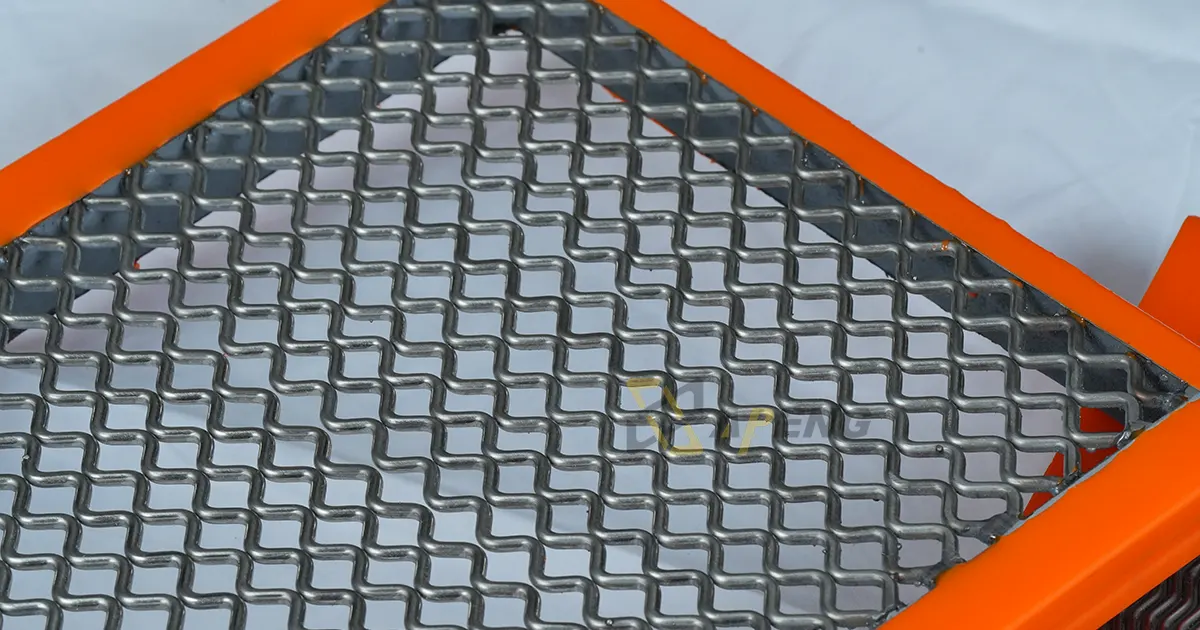

Self-cleaning screens are a game-changer when you deal with sticky or wet materials. These screens have a special design with wires that move and flex. This movement stops material from clogging the openings. You don’t have to stop and clean the screens as often, so your work keeps moving.

Some self-cleaning screens use an automatic brush shower. This feature keeps spray nozzles clear and reduces the risk of clogging. You get high capacity and better efficiency, especially when you need to separate fine wet particles.

Wet Material Applications

You’ll see self-cleaning screens in mining, recycling, and concrete industries. These sectors often deal with wet, sticky, or hard-to-handle materials. Self-cleaning screens help you keep your operation running smoothly. You don’t lose time stopping for maintenance.

If you work with wet sand, clay, or recycled concrete, self-cleaning screens can boost your throughput. You get more done with less downtime. These types of screen mesh are perfect for tough jobs where regular screens might fail.

Polyurethane Screens

Durability

Polyurethane screens stand out for their toughness. You can use them in places where other types of screen mesh wear out fast. Polyurethane has special chemical and physical properties. It stays strong even when you use it every day.

Here’s what makes polyurethane screens last:

- Hard segments in the material give resilience for high-frequency screening.

- The structure spreads out stress, so the mesh doesn’t tear easily.

- Additives like alumina and tungsten carbide cut down on wear.

- Polyurethane stays flexible, even in freezing weather.

- UV stabilizers keep the mesh strong, even after long exposure to solar rays.

You can count on polyurethane screens to keep working, even when the job gets rough.

Abrasive Environments

If you work with sharp rocks or harsh chemicals, polyurethane screens are a great pick. They handle abrasives and chemicals better than many other types of screen mesh. The mesh flexes when hit, then returns to shape. Regular woven wire mesh can break or wear down quickly in these spots, but polyurethane keeps going.

You also get good chemical resistance. Polyurethane screens don’t rust or corrode like some metal screens. They handle vibration and impact without cracking. If you need a screen for a tough job, polyurethane is a top choice.

Tip: When you need a screen for high-wear or chemical-heavy jobs, try polyurethane screens. They last longer and save you money on replacements.

You can see that each type of screen mesh has its own place. Whether you need woven wire mesh, self-cleaning screens, or polyurethane screens, you have options for every job. The right choice helps you get the best results and keeps your operation running smoothly.

Urethane Panels

Heavy-Duty Use

You need a screen that can handle tough jobs. Urethane panels are built for heavy-duty use. You see them in places where other types of screen mesh wear out fast. These panels work well in mining, quarrying, and recycling. They stand up to wet, sticky, and abrasive materials. You can count on them for long service life.

Let’s compare urethane panels with other types of screen mesh:

| Feature | Urethane Screen Panels | Woven Wire Screens | Self-Cleaning Screens | PU Mesh Screens |

|---|---|---|---|---|

| Lifespan | Long (12–18 months) | Short (1.5–2.5 mo) | Medium (6–10 mo) | Long (12–18 mo) |

| Wear Resistance | Excellent | Fair | Good | Excellent |

| Noise Level | Low | High | Medium | Low |

| Clogging/Blinding | Rare | Common | Rare | Rare |

| Upfront Cost | High | Low | Medium | High |

| Maintenance | Easy (modular) | Frequent | Moderate | Easy (modular) |

| Chemical Resistance | High | Low | Medium | High |

| Screening Accuracy | Good | Excellent | Good | Good |

| Throughput | High | High | High | High |

| Best For | Heavy-duty, wet, sticky, abrasive jobs | Fast swaps, low cost | Sticky/wet material | Fine screening, quiet operation |

You get less noise with urethane panels. You also see less clogging. These panels are easy to maintain. You can swap out damaged sections without much trouble. If you need a screen for a busy, rough job site, urethane panels are a smart pick.

Impact Resistance

You want a screen that can take a hit and keep working. Urethane panels have top-notch impact resistance. They absorb energy from falling rocks and heavy loads. This means they last longer and need fewer repairs.

Here’s what makes urethane panels stand out:

| Feature | Rating/Description |

|---|---|

| Elasticity | 3-8 times that of natural rubber |

| Wear resistance | 3-5 times that of steel plates |

| Service life | 8-10 times that of metal screens |

| Impact resistance | ★★★★★ (Absorbed kinetic energy > 50J) |

| Efficiency increase | 20%-40% due to elastic properties |

You get more uptime and less downtime. The panels bounce back after each impact. You can trust them in places where other screens break or wear out. If you want to boost your screening efficiency, urethane panels are a great choice.

Industrial Applications

Mining

You work in mining, so you know how important it is to separate valuable minerals from waste. The right screens make your job easier and faster. You can choose from several types, each with its own strengths:

- Inclined screens are simple and cost-effective. You can adjust them for different jobs.

- Horizontal screens give you more accuracy and higher capacity. They work well when you have limited space.

- Vibrating screens handle both wet and dry materials. You can use them for scalping or classifying.

- Trommel screens use a rotating drum to sort materials by size. They are great for soil, compost, and waste.

You want your screens to last, so you might pick steel or polyurethane mesh. These materials stand up to heavy rocks and sharp edges. If you need extra protection from wear, polyurethane is a smart choice. You can also use aluminum screens for lighter jobs. They are easy to move and install.

Quarry & Aggregate

In quarries and aggregate plants, you deal with rocks, sand, and gravel every day. You need screens that can handle tough materials and keep working without much downtime. Here are some things you should think about:

- Particle size and shape

- Moisture in the material

- How abrasive the rocks are

- The type of screen and how it moves

- How much material you need to process

You might use woven wire mesh for high open-area and good screening. Rubber or polyurethane panels last longer if you work with sharp or heavy rocks. Inclined screens use gravity to move material, which saves energy. Horizontal screens keep material on the mesh longer, so you get better sorting.

ANPENG screens use flexible polyurethane mats and special vibration. This design keeps the mesh clear, even with sticky or wet materials.

When you pick a screen, think about how many tons you need to process each hour, the size of the rocks, and how wet the material is. You want to keep your operation running smoothly, so easy maintenance is a big plus.

Recycling

Recycling plants use screens to sort paper, plastic, glass, and metal. You want to recover as much as possible, so picking the right mesh matters. Wire mesh helps you bale materials tightly. This makes handling and moving bales easier.

Trommel screens are common in recycling. You can use them to separate materials by size, which boosts your throughput. Wire mesh in shredders controls the size of pieces, so everything fits the next step in the process.

You might use fiberglass or aluminum mesh for special jobs. Fiberglass works well when you need lightweight screens that resist rust. Aluminum screens are strong and easy to clean. If you recycle electronics or appliances, you need screens that can handle sharp metal and glass. You also want to keep your workers safe, so screens provide protection from flying debris.

If you have a lot of dust or small particles, you can use window screen mesh to keep the air clean. Some recycling centers use insect screens to stop bugs from getting inside. If you have a pet at your facility, you might want pet-resistant mesh to keep animals safe.

Construction

You see screen mesh everywhere on construction sites. It helps you sort sand, gravel, and crushed stone. You also use it to keep debris out of drains and protect workers from falling objects. When you pick the right screen mesh for construction, you make your job safer and more efficient.

You have many choices for screen mesh in construction. Woven wire mesh is a favorite because it works for many tasks. Welded wire mesh gives you extra stability. You might use it for concrete reinforcement or as a safety barrier. Polyurethane screens help when you need something tough that can handle lots of wear. You can even find specialty screens for dust control or insect protection.

Let’s look at what matters most when you choose screen mesh for construction. You want to match the mesh to your job. Here’s a table to help you see the key things to consider:

| Criteria | Description |

|---|---|

| Opening Size | Match the mesh opening size to the size of the particles you need to filter or screen. |

| Wire Diameter | Thicker wires offer greater strength and durability; thinner wires provide a higher open area. |

| Material | Stainless steel is ideal for corrosive environments; galvanized steel is cost-effective. |

| Open Area Percentage | A higher open area allows for better flow rates but may reduce filtration efficiency. |

| Mesh Type | Woven wire mesh is versatile; welded wire mesh offers greater stability for construction. |

You want to think about what you need the mesh to do. If you need to filter fine sand, pick a mesh with small openings. For bigger rocks, use a mesh with larger gaps. Thicker wires last longer, but thinner wires let more material pass through. Stainless steel mesh works well if you deal with water or chemicals. Galvanized steel saves money and still gives you good strength.

You also need to look at how much material you want to move. A mesh with a high open area lets more sand or gravel pass through. This helps you finish jobs faster. Sometimes, you need to balance speed with how well the mesh filters out unwanted pieces.

Here are some common uses for screen mesh in construction:

- Sifting sand and gravel for concrete mixes

- Reinforcing concrete slabs and walls

- Covering drains to block debris

- Creating safety barriers around work zones

- Protecting workers from falling tools or materials

Tip: Always check your mesh before you start a big job. Make sure it has no damage or rust. A strong, clean mesh keeps your project on track and your team safe.

You can see that picking the right screen mesh makes a big difference. You get better results, save time, and keep everyone safer on site. Next time you plan a construction project, take a close look at your screen mesh options. The right choice helps you build with confidence.

Choosing the Right Screen Mesh

Material Properties

You want your screen mesh to last and perform well. The material you choose makes a big difference. Each industry has its own needs. Here’s how material properties guide your choice:

- In mining and mineral processing, you deal with tough, abrasive materials. You need high-strength meshes that can handle heavy wear and keep sizing consistent.

- In agriculture and food processing, you want clean and safe products. Stainless steel meshes help you sieve flour or remove impurities. They boost quality and keep food safe.

- In chemical and pharmaceutical work, you need pure results. Fine meshes filter out unwanted particles and prevent contamination.

Think about what you need your screen to do. If you work with chemicals, pick a mesh that resists corrosion. For food, choose a material that’s easy to clean and won’t rust. If you handle rocks or minerals, go for something strong and durable.

Mesh Size Selection

Picking the right mesh size is key. You want to balance how well the screen separates materials and how fast things move through it. Finer meshes catch smaller particles but slow down the flow. Coarser meshes let things move faster but might miss tiny pieces.

Here’s a simple way to choose the best mesh size:

- Do a sieve analysis. This helps you see the range of particle sizes in your material.

- Look at the material’s traits. Is it wet, heavy, or sharp? These things affect your choice.

- Decide how clean you want your final product. Finer mesh gives better separation but may slow things down.

- Think about how much you need to process. You want a mesh that keeps up with your production goals.

You can also use a set of sieves to check particle sizes. Industry standards can guide you on common mesh sizes. Sometimes, you need to test a few options to find what works best. The type of vibrating sieve you use can also change your results.

Tip: Always match your mesh size to your material and your goals. This helps you get the best mix of speed and accuracy.

Wear Resistance

You want your screen mesh to last as long as possible. Wear resistance depends on the material, design, and how you use the screen. Here are some ways to make your screens last longer:

- Check your screens often. Inspections help you spot wear before it causes problems.

- Clean your screens after each use. This stops blockages and keeps performance high.

- Store screens in a clean, dry place. This prevents rust and damage.

- Use the right material for your job. Stronger materials and smart designs last longer.

Regular maintenance and cleaning are your best friends. If you take care of your screens, you’ll have less downtime and fewer replacements. That means more time working and less time fixing problems.

Efficiency

You want your screening process to run smoothly and quickly. Efficiency means you get the most out of your screen mesh with the least amount of wasted time or material. When you pick the right mesh, you help your operation work better and faster.

Several things affect how efficient your screen mesh will be. Let’s break them down:

- Screen Material and Surface Treatment: The type of material you choose matters. Stainless steel, polyurethane, and rubber all have different strengths. Some last longer, while others resist clogging or handle wet materials better. A good surface treatment can also help materials move across the mesh without sticking.

- Mesh Count and Aperture Size: Mesh count tells you how many openings are in one inch of mesh. Aperture size is the size of each opening. If you need to separate fine particles, you might pick a higher mesh count. But if the mesh is too fine, it can clog up. You want to match the mesh size to the size of the material you’re screening.

- Screen Tension and Tensioning: Tight screens work better. If your mesh is loose, it can sag and let the wrong size particles through. Proper tension keeps the mesh flat and helps you get accurate results.

- Material Properties and Screen Compatibility: Think about what you’re screening. Wet, sticky, or sharp materials need special mesh types. If you match the mesh to your material, you get better efficiency and fewer problems.

- Vibration Type and Screen Compatibility: Your equipment matters too. Some screens work best with certain types of vibration. If you match your mesh to your machine, you boost your screening speed and accuracy.

You can also look at a few more factors to get the best results:

| Factor | Why It Matters |

|---|---|

| Screening Accuracy | Finer mesh gives you better separation, but it might slow down how fast material moves through. |

| Required Capacity | If you need to process a lot of material, you may need a coarser mesh to keep up. |

| Number of Separations | Multi-deck screens let you sort materials into several sizes at once. This saves time and increases efficiency. |

Tip: Always check your screens for blockages or damage. Clean and maintain them often. A clean, well-tensioned screen works faster and lasts longer.

If you want to improve efficiency, start by looking at your current setup. Ask yourself these questions:

- Are you getting the right size material out of your screens?

- Do you see a lot of blockages or slowdowns?

- Is your mesh wearing out too quickly?

You can often boost efficiency by making small changes. Try adjusting the mesh size, tightening the screen, or switching to a different material. Sometimes, adding another deck to your screen lets you sort more sizes at once.

Remember, the right screen mesh helps you save time, reduce waste, and get better results. When you focus on efficiency, your whole operation runs smoother.

Mesh Type Advantages

Woven Wire Mesh

You see woven wire mesh in many places, from mining sites to your own window screen at home. This mesh stands out because it bends easily and fits odd shapes. You can pick the wire thickness, hole size, and even the material. That means you get a custom fit for your job. Woven wire mesh costs less than many other screens and needs less maintenance.

Here’s a quick look at the main advantages and disadvantages:

| Advantage/Disadvantage | Description |

|---|---|

| Flexibility | Fits odd shapes and works in many places. |

| Customization | Choose wire thickness, hole size, and material. |

| Cost-Effectiveness | Lower price and less upkeep. |

| Lower Strength | Not as strong as welded mesh. |

| Unraveling Risk | Can come apart if cut or damaged. |

You might use woven wire mesh for sorting rocks, making a window screen, or even as an insect barrier. It works well for many jobs, but it’s not the best for heavy-duty tasks. If you need something strong, you may want to look at other types of screens.

Self-Cleaning Screens

If you deal with sticky or wet materials, self-cleaning screens can save you a lot of trouble. These screens have wires that move and flex, so they don’t clog up as easily. You spend less time cleaning and more time working. In fact, you can cut your manual cleaning hours by almost half. Maintenance costs drop by up to 30%. You also get more uptime, especially when there’s a lot of debris.

- Self-cleaning screens keep your operation running.

- You don’t have to stop as often for cleaning.

- These screens work well in recycling, mining, and even in places where you need to keep out insect pests.

Tip: If you want to boost efficiency and lower costs, try self-cleaning screens for tough jobs.

Polyurethane Screens

Polyurethane screens bring you strength and long life. You can use them in mining, recycling, or food plants. These screens last up to five times longer than traditional ones. You change them less often, which saves you money. In a mining plant, polyurethane screens cut operational costs by 20%. In a recycling plant, they improved sorting accuracy by 30% and used 25% less energy.

Here’s why you might pick polyurethane screens:

- They handle both wet and dry materials.

- They reduce wear and tear on your equipment.

- They help you sort materials more accurately.

You can even use polyurethane screens in places where you need a window screen or insect protection. They work well with fiberglass and aluminum, giving you more choices. If you want a screen that lasts and helps you work faster, polyurethane is a smart pick.

Urethane Panels

You need a screen that works for hard jobs and lasts long. Urethane panels help you do this. These panels are strong, flexible, and save money. You see them in mining, quarrying, and recycling plants. They work well where other screens break down fast.

Here’s why urethane panels are a good choice:

- Urethane panels fight off wear better than most mesh. You don’t have to change them as much.

- These panels bend under heavy loads. They bounce back instead of breaking.

- You spend less money over time. You don’t need to replace them often, so you save on repairs.

- Urethane panels don’t clog easily. Material moves through fast, so your work keeps going.

You might want to know how urethane panels compare to other screens. Here’s a table to show the differences:

| Mesh Type | Durability | Blinding Resistance | Replacement Frequency | Cost-Effectiveness |

|---|---|---|---|---|

| Urethane Panels | Excellent | High | Low | High |

| Steel Screens | Good | Low | High | Medium |

| Rubber Screens | Good | Medium | Medium | Medium |

| Polyurethane Mesh | Excellent | High | Low | High |

Urethane panels last longer than most screens. Steel screens let more material through, but they wear out and clog faster. Rubber screens take hits well, but don’t last as long with rough materials. Polyurethane mesh is tough too, but urethane panels are even more flexible and strong.

Here’s why you might choose urethane panels for your job:

- You want to do less fixing and cleaning.

- You need a screen for sharp rocks and heavy stuff.

- You want to save money by changing screens less.

Tip: If you want a screen that keeps working in tough places, pick urethane panels. You get more work done and fewer problems.

You can count on urethane panels to work well every year. They help your work go smoothly and save you money over time.

Conclusion

Now you know that screen mesh isn’t “one-size-fits-all.” Different materials and designs are made for different jobs. Woven wire mesh is a popular choice for many mining and aggregate applications because it offers good accuracy and open area. Self-cleaning screens are often used when blinding or pegging becomes a problem, especially with wet, sticky, or clay-heavy feed. PU/urethane and rubber screens are better when you need longer wear life and quieter operation in high-abrasion or high-impact areas. And perforated plate (punch plate) is a solid option for heavy-duty scalping and protection.

The best approach is simple: start with your material (moisture, fines, and particle shape), define your target cut size and throughput, then match the mesh type to the duty of each deck.

As a manufacturer of industrial screening media, ANPENG can help you choose the right screen mesh for your application—just share your material type, moisture level, target cut size, throughput, and screen model/deck layout.

FAQ

What is the difference between mesh size and aperture?

Mesh size tells you how many openings fit in one inch of screen. Aperture means the size of each opening. Both help you pick the right screen for your job.

How do I clean a clogged screen mesh?

First, stop your machine. Use a soft brush or water to clear the mesh. For tough clogs, try a gentle spray. Avoid sharp tools. They can damage the mesh.

Which screen mesh lasts the longest?

Polyurethane and urethane panels last the longest. They resist wear, impact, and chemicals. You change them less often, so you save money and time.

What mesh should I use for wet materials?

Self-cleaning screens work best for wet or sticky materials. They flex and move, so they do not clog easily. You get better results and less downtime.

How do I choose the right mesh for my project?

Start by looking at your material. Check the size, shape, and if it is wet or dry. Pick a mesh that matches your needs. If you are not sure, ask an expert for help.