You can use an easy formula to find the open area of woven wire mesh.

Open Area % = ((Aperture Width²) / (Aperture Width + Wire Diameter)²) × 100.

This percentage helps you choose the best mesh for your work. It ensures you get good airflow, filtration, or screening. If you want to know how to calculate open area of woven wire mesh, you are in the right spot. Follow these steps and you will get clear answers each time.

Key Takeaways

- Use this formula to find Open Area %: ((Aperture Width²) / (Aperture Width + Wire Diameter)²) × 100. This helps you calculate the open area of woven wire mesh.

- Learn these key words: Mesh Count means how many openings are in one inch. Wire Diameter is how thick the wire is. Aperture is the space between the wires.

- If the open area percentage is higher, more air can flow through. It also helps with filtration. If the percentage is lower, the mesh is stronger and gives more protection.

- You need to measure carefully. Use calipers to check aperture width. Use a micrometer to measure wire diameter. This makes sure your measurements are correct.

- Always pick the open area percentage that fits your project. Higher percentages are good for airflow. Lower percentages are better if you need strength.

- Look for manufacturing tolerances. Make sure you use the same units when you calculate. This helps you avoid mistakes in your open area percentage.

- Think about the weave type and wire diameter. These things change the open area and how the mesh works.

- Ask manufacturers for help if you need to choose the right mesh. They can also give you tools to help with your calculations.

Formula to Calculate Open Area

Standard Formula for Woven Wire Mesh

You can find out the percentage of open area with a simple formula. This formula shows how much space is open for things to pass through. You can use it for air, water, or light. Here is a table that explains what each part means:

| Variable | Description |

|---|---|

| A | Aperture width (distance between two adjacent wires) |

| B | Wire diameter (thickness of the individual wires) |

| Formula | Open Area % = ((A²) / (A + B)²) × 100 |

Most woven wire mesh types use this formula. It helps you compare different mesh choices with a clear number.

Key Terms: Mesh Count, Wire Diameter, Aperture

Let’s look at some important words you will see with wire mesh:

- Mesh Count: This tells you how many openings are in one inch. If you count 10 openings in one inch, it is called 10 mesh.

- Wire Diameter: This means how thick each wire is. Thicker wires make the mesh stronger but leave less open space.

- Aperture: This is the size of the opening between two wires. Bigger apertures mean more open space.

Wire diameter and mesh count work together. If the wires are thick, the openings get smaller. This lowers the percentage of open area. Less air or liquid can go through. If the wires are thin, the openings get bigger. This raises the percentage of open area. More air or liquid can pass, but the mesh is not as strong. You need to pick what works best for your project.

Why Percentage of Open Area Matters

The percentage of open area is very important when you choose woven wire mesh. This number shows how much of the mesh is open space. You should match the percentage of open area to what you need.

- If you want good airflow or easy liquid flow, pick a higher percentage of open area.

- If you need to block small things or want more strength, a lower percentage of open area may be better.

Here is a table that shows how different industries use open area standards:

| Industry Standard | Application Description |

|---|---|

| FDA CFR Title 21 | Food contact surface requirements |

| 3-A Sanitary Standards | Dairy and food processing equipment |

| ASME BPE | Bioprocessing equipment standards |

| API Standards | Petroleum industry specifications |

Tip: The percentage of open area is the ratio of all open spaces to the total mesh area. This number is very important for jobs that need a certain flow rate, like filtration or screening.

A higher percentage of open area means air, water, or light can move better. This helps with filtration because it lowers pressure and saves energy. In building design, it lets in more light but still gives shade. Always check the percentage of open area before you pick your wire mesh.

How to Calculate Open Area of Woven Wire Mesh

You want to know how to calculate open area of woven wire mesh? Let’s break it down into simple steps. This step-by-step guide will help you get the percentage of open area right every time. You only need a few tools and a little patience.

Gather Measurements

Before you start, you need to collect some measurements. These numbers are the key to finding the percentage of open area. Grab your mesh sample and let’s get started.

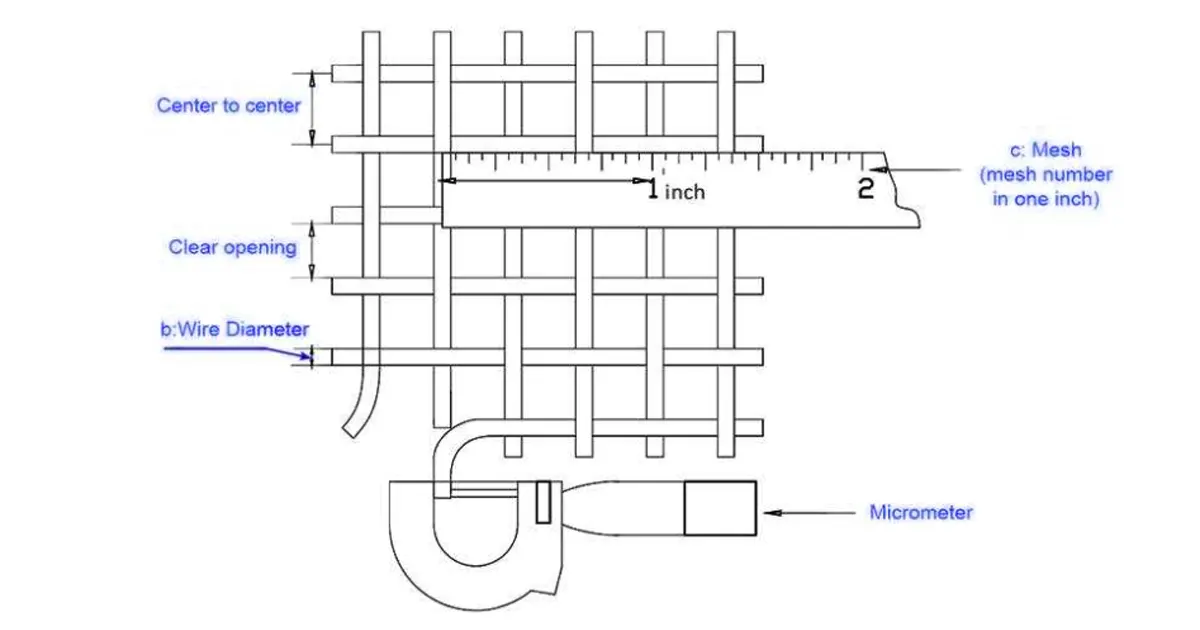

Measuring Mesh Count

Mesh count tells you how many openings sit in one inch of your wire mesh. You can measure this by counting the number of openings from the center of one wire to a point one inch away. Use a ruler or a magnifying glass if the mesh is fine. Here’s a quick look at the best ways to measure:

| Measurement Method | Description |

|---|---|

| Mesh Count | The number of openings in a linear inch measured from the center of one wire to a point one inch distant. |

| Center-to-Center | Measured from the center of one wire to the center of the next adjacent parallel wire. |

Tip: For very fine mesh, use an optical projector or a scanner to count the openings. This makes it easier to see small details.

Measuring Wire Diameter

Wire diameter is the thickness of each wire in your mesh. You need this number to figure out the percentage of open area. The best tool for this job is a micrometer. Place the micrometer on a single wire and read the measurement. Try to check wires in both directions for the most accurate result.

| Measurement Method | Description |

|---|---|

| Wire Diameter | Checked with a micrometer, measuring diameters in both directions. |

- You can also use a micrometer screw for loose wires.

- If the wires are still in the mesh, measure them if there is enough space.

- For tricky spots, try an optical method.

Note: Always double-check your measurements. Even a small mistake can change the percentage of open area.

Apply the Formula

Now you have your numbers. It’s time to use the formula for how to calculate open area of woven wire mesh. Make sure you use the same units for both measurements. Here’s how you do it:

- Measure the aperture width (A). Use calipers to go from the center of one wire to the center of the next.

- Measure the wire diameter (B) with your micrometer or calipers.

- Check that both A and B use the same units, like millimeters or inches.

- Plug your numbers into the formula:

Open Area % = ((Aperture Width²) / (Aperture Width + Wire Diameter)²) × 100

This formula helps you calculate open area for any woven wire mesh. You can write your numbers on paper or use a calculator.Calculate Open Area Percentage

You have your measurements and you know the formula. Now, let’s finish the job and get the percentage of open area.

- Square the aperture width.

- Add the aperture width and wire diameter, then square that total.

- Divide the first number by the second.

- Multiply by 100 to get the percentage of open area.

Tip: Always use precise tools and double-check your math. This keeps your open area percentage accurate.

Tips for Accurate Measurement

You want your results to be spot-on. Here are some tips to help you get the best numbers:

- Thicker wires lower the percentage of open area.

- Higher mesh counts also reduce the percentage of open area.

- Bigger openings raise the percentage of open area.

- The type of weave matters. Tighter weaves mean a lower percentage of open area.

- Stronger wire alloys let you use thinner wires, which can boost the percentage of open area without losing strength.

Callout: Always look over your mesh before you measure. Fix any errors or bent wires. This makes your results more reliable.

If you follow these steps, you will always know how to calculate open area of woven wire mesh. You can use this method for any project, big or small. The percentage of open area helps you pick the right mesh for airflow, screening, or filtration. With careful measuring and a little practice, you will get the open area percentage right every time.

Example: Calculate Open Area

Sample Mesh Specifications

Let’s look at a real-world example. Imagine you want to pick a woven wire mesh for an industrial screening job. You need to know the percentage of open area to make the right choice. Here are some common mesh specifications you might see:

- Mesh count: 10 openings per inch

- Wire diameter: 0.025 inches

- Material: T-304 stainless steel (strong and corrosion-resistant)

- Aperture width: 0.075 inches

You can find these specs in many screening applications. T-304 stainless steel works well because it stands up to rust and lasts a long time. You might also see aluminum, bronze, or copper used for different jobs. Each material has its own strengths. For example, aluminum is light and resists corrosion. Bronze is strong and has a unique look. Copper develops a patina over time, which some people like for style.

Industry standards like ASTM E 2016 and ISO 9044 help make sure your wire mesh meets quality rules. These standards cover things like wire diameter tolerances and inspection steps.

Step 1: Identify Mesh Count and Wire Diameter

You need to start by finding the mesh count and wire diameter. Mesh count tells you how many openings fit in one inch. This number affects how well your mesh filters or screens materials. Wire diameter shows how thick each wire is. Thicker wires make the mesh stronger but lower the percentage of open area.

Here’s a quick checklist to help you:

- Count the number of openings in one inch. That’s your mesh count.

- Measure the thickness of one wire with a micrometer. That’s your wire diameter.

Both numbers matter. Mesh count changes how much stuff can pass through. Wire diameter changes how strong your mesh is and how much open space you get.

Tip: Always double-check your measurements. Even a small mistake can change the percentage of open area.

Step 2: Use the Formula

Now you have your numbers. You can use the formula to find the percentage of open area. Here’s how you do it:

- Write down your aperture width (0.075 inches) and wire diameter (0.025 inches).

- Plug these numbers into the formula:

Open Area % = ((Aperture Width²) / (Aperture Width + Wire Diameter)²) × 100

- Do the math step by step:

- Square the aperture width: 0.075 × 0.075 = 0.005625

- Add the aperture width and wire diameter: 0.075 + 0.025 = 0.1

- Square that total: 0.1 × 0.1 = 0.01

- Divide the first number by the second: 0.005625 ÷ 0.01 = 0.5625

- Multiply by 100 to get the percentage of open area: 0.5625 × 100 = 56.25%

So, your open area percentage is 56.25%. This means over half of your wire mesh is open space. You can use this number to compare different mesh types and pick the best one for your job.

Note: Always use the same units for all your measurements. This keeps your open area calculation correct.

Step 3: Interpret Results

You just finished the math and found your percentage of open area. Now, let’s talk about what this number means for your project. When you see a percentage like 56.25%, you might wonder, “Is that good for my needs?” Here’s how you can make sense of your results.

First, remember what the percentage of open area tells you. This number shows how much of your woven wire mesh is actually open space. The rest is wire. If you have a high percentage of open area, more air, water, or light can pass through. If the percentage is low, less can get through, but your mesh will be stronger.

Let’s break it down:

- High percentage of open area (above 50%)

You get lots of flow. This works well for jobs like air filters, water screens, or anything that needs easy movement through the mesh. - Medium percentage of open area (30%–50%)

You get a balance. This is good for things like safety guards or light screening. You still get some flow, but the mesh stays strong. - Low percentage of open area (below 30%)

You get more strength and protection. Use this for security screens or when you need to block small particles.

Tip: Always match the percentage of open area to your job. If you need more flow, go higher. If you need more strength, go lower.

Here’s a quick table to help you compare:

| Percentage of Open Area | Best Use Cases |

|---|---|

| 50% and above | Airflow, filtration, sieving |

| 30% – 50% | Safety guards, light screens |

| Below 30% | Security, fine particle block |

You can use the percentage of open area to compare different wire mesh options. If you look at two samples, pick the one with the percentage that fits your needs. Don’t forget to check the wire diameter and mesh count too. These numbers work together to give you the right mix of strength and flow.

If you want to change the percentage of open area, you can try a few things:

- Pick a mesh with thinner wires. This raises the percentage of open area.

- Choose a mesh with bigger openings. This also increases the percentage of open area.

- For more strength, use thicker wires or a tighter weave. This lowers the percentage of open area.

Note: The percentage of open area is not just a number. It helps you make smart choices for your project. Always check this number before you buy or use any woven wire mesh.

Now you know how to calculate and use the percentage of open area. You can pick the best wire mesh for airflow, screening, or protection. This skill helps you get better results every time.

Factors Affecting Open Area

If you want your woven wire mesh to work well, you need to know what can change the open area. Many things can change how much space is open for air, water, or light. Let’s talk about the main things that matter.

Wire Diameter Impact

Wire diameter is very important for open area. Thicker wires take up more space. This means there is less room for openings. Thinner wires leave more space open. The screen coefficient tells you how much mesh is open compared to the wire. If you change the wire diameter, the open area percentage changes too. Thin wires give you more open area. If you want your mesh to be strong, you might pick thick wires. But then you will have less open space.

Tip: Always look at the wire diameter before you buy. Even small changes can make a big difference in how your mesh works.

Mesh Type Differences

How the wires are woven also changes the open area. There are different weaves, and each one is special.

Plain Weave vs. Twill Weave

Here is a table that shows how different weaves compare:

| Weave Type | Statistical Significance | Open Area Impact |

|---|---|---|

| Plain Weave (PW) | Not significant | Similar to T2/2 |

| Twill 2/2 (T2/2) | Not significant | Similar to PW |

| Warp Rib (R2/4) | Not significant | Similar to R4/2 |

| Filling Rib (R4/2) | Not significant | Similar to R2/4 |

Plain weave and twill weave have almost the same open area. You can pick either one for your project. The choice depends on how strong or bendy you want your mesh.

Crimped Wire Mesh

Crimped wire mesh uses wires that are bent before weaving. This makes the mesh stronger and helps it keep its shape. Crimping can change the open area a little bit. But it mostly makes the mesh last longer and stay in place.

Manufacturing Tolerances

Manufacturing tolerances can change the open area you get. Makers try to keep wire diameter and aperture size close to the specs. But small differences can happen. These small changes can affect how much air, water, or light goes through your mesh.

- The open area percentage shows how much empty space is in your mesh. This changes how well air, water, and light move through.

- More open area means better flow for filtration and ventilation.

- You need to figure out open area to make sure your mesh fits your project.

Note: Always ask about the tolerance details when you order wire mesh. This helps you avoid surprises and get what you need.

Here is a table that shows how things like temperature and humidity can change open area measurements:

| Effect | Description |

|---|---|

| Particle Suspension | High humidity makes particles heavier, so they move differently in the mesh. |

| Chemical Reactions | Humidity can change chemical reactions and may affect mesh performance in some places. |

| Sensor Performance | Moisture can make sensors less accurate, so measurements might not be right. |

| Increased Settling | Wet particles fall faster, which can change how you measure open area in air filtration. |

| Reduced Suspension | Heavy particles stay in the mesh instead of floating, so there are fewer in the air. |

| Altered Distribution | Particle weight changes how they spread, which can change air monitoring results. |

When you know about these things, you can make better choices for your woven wire mesh. You will get the right open area for your job and avoid problems later.

Applying Open Area Knowledge

Choosing the right mesh for your project can feel tricky. You want to make sure you get the best results for your needs. When you understand how open area works, you can match the mesh to your application with confidence.

Matching Mesh to Application

Every job needs something different from woven wire mesh. You need to think about what you want the mesh to do. Here are some tips for picking the right mesh for your project.

Screening and Sizing

If you need to separate materials by size, focus on the open area. A higher open area percentage lets more material pass through quickly. This works well for sorting rocks, sand, or grains. If you want to catch smaller pieces, pick a mesh with smaller openings. Always check the smallest particle you need to filter out before you choose.

Filtration and Separation

For filtration, you want to know what you are filtering and the type of fluid. Liquids and gases move differently through wire mesh. If you use the mesh in a place with high pressure or heat, pick a material that can handle those conditions. Stainless steel or titanium works well in tough spots. Finer mesh may need more cleaning or replacement, so think about how often you want to do maintenance.

Here’s a table to help you decide:

| Factor | Description |

|---|---|

| What you will be filtering | Identify the smallest particle size that needs to be filtered out. |

| Type of Fluid | The mesh filter size varies for liquids and gases. |

| Conditions of Use | Filtering resistance is influenced by temperature and pressure. |

| Compatibility | Corrosive environments require materials like stainless steel or titanium. |

| Replacement Frequency | Finer mesh requires more frequent cleaning or replacement. |

Airflow and Light Transmission

If you want good airflow or more light, look for a mesh with a high open area. This helps air move freely and lets in more sunlight. You might use this for window screens, vents, or architectural features. Always balance the need for flow with the strength you need.

Tip: Always match the open area to your job. More open area means better flow, but less strength. Less open area gives you more strength, but less flow.

Common Calculation Mistakes

You want your results to be right. Here are some mistakes people often make when working with open area:

- Using different units for aperture and wire diameter. Always use the same units.

- Measuring the wrong part of the mesh. Measure from the center of one wire to the center of the next.

- Forgetting to check for bent or damaged wires. This can change your results.

- Not double-checking your math. A small mistake can lead to the wrong open area percentage.

- Ignoring the type of weave. Some weaves change the open area more than you think.

Note: Take your time with each step. Careful measuring and checking help you avoid costly errors.

When you follow these tips, you can pick the best wire mesh for your project. You will get the right balance of strength, flow, and durability every time.

Tips for Choosing Woven Wire Mesh

Balancing Strength and Open Area

You want your mesh to be strong, but you also want enough open space for things to pass through. Finding the right balance can feel tricky, but you have some smart strategies to help you out:

- Try different opening sizes. Bigger openings give you more flow, but smaller ones make the mesh stronger.

- Look at the wire diameter. Thicker wires add strength, but they take up more space and lower the open area.

- Think about the shape of the mesh. The way the wires cross each other can change how well the mesh catches particles.

- Use layered mesh designs. You can put a fine mesh on top of a stronger, coarser mesh. This gives you good filtration and keeps the mesh from bending or breaking.

- Test your mesh in real life. Sometimes, you need to see how it works with your materials. You can also use computer models to help you choose the best size.

- Remember your project’s needs. If you need to keep things pure, like in hydrogen systems, pick a mesh that matches your purity and flow requirements.

Tip: If you want less maintenance, choose a mesh that is strong enough to last but still lets enough material pass through.

Consulting Manufacturers

You don’t have to figure everything out on your own. Mesh manufacturers offer lots of help when you need to pick the right mesh or calculate open area. Here’s what you can expect:

| Service Type | Description |

|---|---|

| Free Calculation Tools | Get quick and accurate tools to figure out mesh weight and open area. |

| Guidance on Mesh Selection | Ask for advice on the best mesh for your project’s needs. |

You can also find helpful guides and articles online. These resources explain why open area matters and show you how to compare different mesh types. If you ever feel stuck, reach out to a manufacturer’s support team. They can answer your questions and help you avoid mistakes.

Note: Good technical support can save you time and money. Don’t be afraid to ask for help!

Using Open Area Data

Open area data is more than just a number. You can use it to make your project work better and last longer. Here’s how:

- A high open area percentage helps things flow faster. This is great for mining, screening, or when you need lots of air or water to move through.

- More open area means less pressure drop. Your filters won’t clog as fast, and you use less energy.

- Compare different mesh types by looking at their open area. Pick the one that fits your job best.

- For filtration, airflow, or letting in light, always check the open area percentage first.

- If you need both strength and flow, balance the wire thickness with the open area. Don’t pick one and forget the other.

Callout: When you use open area data, you can choose the right woven wire mesh for any job. You get better results and fewer problems.

Conclusion

You want your woven wire mesh to work its best. Accurate open area calculation helps you get the right results for filtration, airflow, and light. When you follow each step, you make sure your mesh fits your needs.

- Open area percentage controls how well your mesh works.

- It helps you match mesh to your project for top performance.

- You can use it for many jobs, like screening or ventilation.

Here’s what to keep in mind:

| Factor | Description |

|---|---|

| Alloy Selection | Pick the right metal for strength and durability. |

| Corrosion Considerations | Watch out for rust and metal reactions. |

| Post-Weaving Processes | Heat treatment can make your mesh last longer. |

| Customization Options | You can order mesh made just for your job. |

ANPENG offers many screening media, like self-cleaning screens with maximum open area for sand, plus PU-mesh screens and more. Need help? Reach out to ANPENG for expert advice and quality solutions.

FAQ

What is open area in woven wire mesh?

Open area means the part of the mesh that is empty space. It shows how much air, water, or light can pass through. You measure it as a percentage.

How do I measure wire diameter at home?

You can use a micrometer or calipers. Place the tool on one wire and read the number. Try to measure a few wires to get the best result.

Why does open area matter for filtration?

Open area controls how much liquid or air can flow through your mesh. More open area means better flow. Less open area gives you more strength but slower flow.

Can I use a ruler to measure mesh count?

Yes, you can! Count the number of openings in one inch using a ruler. For small mesh, use a magnifying glass to help you see better.

What happens if I use the wrong units in the formula?

If you mix up units, your answer will be wrong. Always use the same units for both aperture width and wire diameter. Double-check before you calculate.

Does the type of weave change the open area?

Yes, it can. Plain weave and twill weave have similar open areas. Crimped mesh may change the open area a little. Always check the specs for your mesh type.

How do I choose the right mesh for my project?

Think about what you need—airflow, strength, or filtration. Check the open area percentage. Ask the manufacturer if you feel unsure. They can help you pick the best mesh.