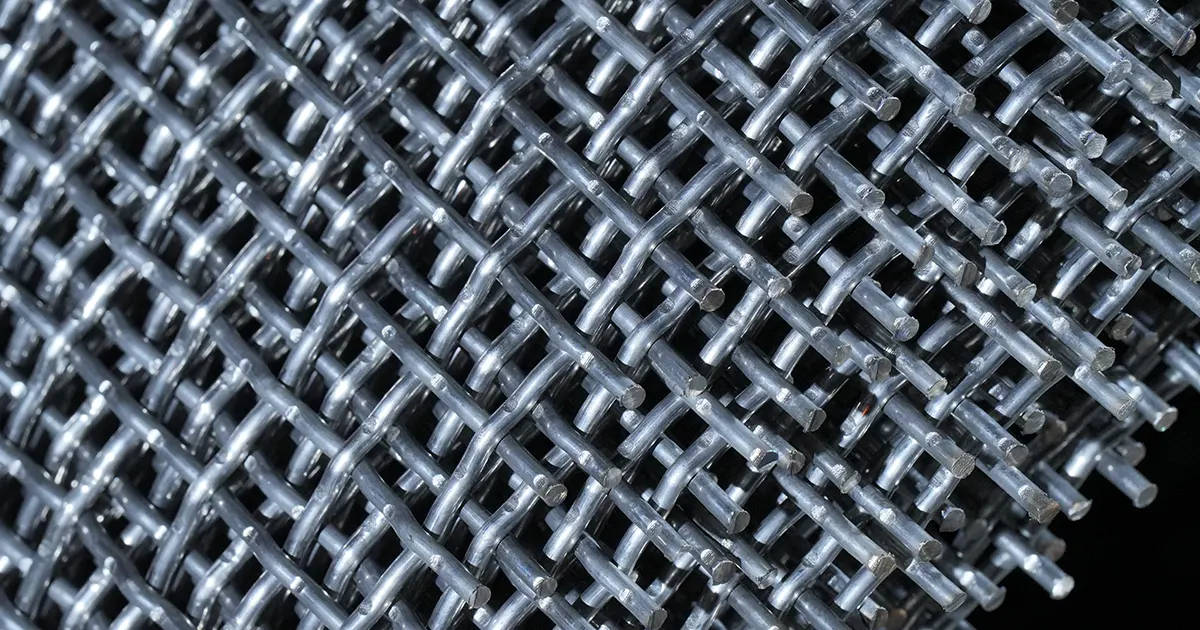

Metal mesh screen material means wire mesh panels made for screening jobs. These jobs include separating, sizing, and filtering big materials. You see them used in mining, quarry, aggregate, recycling, and construction work. Picking the right screen mesh helps you work faster. It also makes your mesh last longer and cuts down on machine stops. You should think about what you need it for, where you use it, mesh features, and your budget.

Key Takeaways

- Pick the right mesh material for your screening job. Carbon steel is good for dry work. Stainless steel is better for wet or rusty places.

- Think about how long the mesh will last and how often you stop work. Stronger materials need fewer changes and help your work go well.

- Make sure the mesh size fits the size of the pieces you want. Small holes separate things better. Big holes let more stuff go through faster.

- Look at how much the mesh will cost over time. Buying better mesh can save money later by needing fewer fixes and less stopping.

- Watch the working conditions. Things like water, heat, and hard materials change how long your mesh lasts and how well it works.

- Make sure you put in the mesh the right way and pull it tight. This stops it from sagging and helps it work better.

- Use self-cleaning screens or PU-mesh for sticky stuff. These choices keep things moving and mean you clean less by hand.

- Check your wire mesh and parts often. Finding problems early can stop long breaks and make your equipment last longer.

Why Metal Mesh Screen Material Selection Matters

Picking the right wire mesh screen material is very important. It can help your screening job work well or cause problems. You want your mesh to last a long time. This helps you save money and avoid stopping your machines too much. Let’s see how your choice changes these important things.

Wear Life and Downtime

When you choose wire mesh for screening, think about how long it will last. If your mesh breaks down fast, you will need to change it often. This means your plant will stop working more. When your machines stop, you lose time and may miss deadlines. Different wire mesh materials last for different times and fight off wear in different ways. Here is a table to compare:

| Material | Durability | Resistance to Abrasion | Suitability for Wet Screening |

|---|---|---|---|

| Steel | High | Moderate | Low |

| Polyurethane | Moderate | High | High |

Steel wire mesh is good for dry and rough jobs. Polyurethane mesh works better for wet jobs or when you need more wear resistance. If you pick the right mesh, you will have fewer problems and won’t need to replace it as much.

Tip: Always use wire mesh that matches what you are screening. This stops early damage and keeps your machines working well.

Total Cost of Ownership

You might think picking the cheapest wire mesh saves money. But that is not always true. The total cost is more than just the price you pay at first. You should think about how often you need to buy new mesh. You also need to think about how much time your machines stop and how much you spend fixing things. Here are some things to remember:

- Wear-resistant wire mesh can help your equipment last longer.

- When you look at costs, think about energy and repairs, not just the first price.

- Buying better mesh may cost more at first, but it can save you money later by stopping breakdowns and helping your plant work better.

If you pick mesh that fits your job, you will spend less on repairs and new mesh. This means your machines run more and your plant does better.

Screening Efficiency

How well you screen depends on the wire mesh you use. The right mesh helps you sort materials faster and more exactly. You should think about hole size, open area, and mesh type. These things change how much material goes through and how well you get the size you want. Look at this table:

| Factor | Impact on Screening Efficiency |

|---|---|

| Hole size of the mesh | Decides what size gets through and how much material you can screen. |

| Free surface of the mesh | More open space means more material can pass; wire thickness changes open space. |

| Type of the mesh | Changes how well you screen, especially for special shapes that need certain mesh types. |

You can use wire mesh screens, punch plates, or bars. Woven wire mesh has the most open space, so more material can go through. The shape of the mesh holes matters too. Rectangular mesh can handle more material but can get blocked faster. Square mesh is better for getting the same size every time.

Note: For the best results, pick wire mesh with the right hole size and open space for your job. This helps you screen more material and reach your quality goals.

If you think about these things, your mesh will last longer, cost less, and work better. The wire mesh you pick helps your plant do its best every day.

Operating Conditions for Metal Mesh Screen Material

When you pick wire mesh for screening, think about the work area. The place where you use the mesh can change how long it lasts. It also changes how well the mesh does its job. Here are some important things to look at.

Abrasion and Impact

Mining and quarry jobs are hard on wire mesh. Rocks and minerals hit the mesh with a lot of force. Sharp materials can wear out the mesh fast. You need mesh that can take these tough jobs.

Mining and Aggregate

Mining and aggregate plants use wire mesh to sort rocks and ore. These materials are rough and can break mesh quickly. Metal mesh is strong and handles big hits well. Polyurethane and rubber mesh are good for areas with lots of sharp rocks. They last longer when you screen rough stones.

| Screen Media Type | Durability | Resistance to Abrasion | Impact Handling | Lifespan Considerations |

|---|---|---|---|---|

| Polyurethane | High | Excellent | Moderate | Longer service life in high-abrasion environments |

| Rubber | High | Excellent | Moderate | Longer service life in high-abrasion environments |

| Metal | Extreme | Good | High | Handles heavy loads but may wear faster in abrasive conditions |

Pick mesh that matches what you are screening. If you work with hard rocks, use mesh that fights abrasion. For heavy hits, metal mesh is a good pick.

Material Hardness

Harder rocks can wear out your mesh faster. Soft rocks do not damage mesh as much. You should know how hard your material is. This helps you choose mesh that lasts longer and keeps your machines running.

Tip: Always check how hard your material is before picking mesh. This helps you stop mesh from breaking too soon.

Moisture and Corrosion

Water and chemicals can hurt wire mesh over time. If you work in wet or chemical places, you need mesh that does not rust or break down.

Wet Screening

Wet screening uses water to help sort materials. Water can make regular mesh rust. Stainless steel mesh and aluminum mesh do not rust. They work well in wet or salty places.

- Aluminum mesh does not rust and is good for wet jobs.

- Stainless steel mesh fights rust from water and chemicals.

The right mesh helps your plant keep working and stops breakdowns.

Chemical Exposure

Some jobs have chemicals that can damage mesh. Acids and other chemicals can eat away at normal mesh. You need mesh that can handle these tough chemicals.

- PU screens fight many chemicals, like acids and solvents.

- Woven wire mesh can rust and break from water and chemicals.

- Epoxy coated mesh has a layer that blocks many chemicals.

Epoxy coatings help mesh last longer in chemical places. The type of epoxy matters, so ask your supplier for the best one.

Temperature Effects

Screening can happen in very hot or cold places. Heat and cold can change how mesh works. Some mesh gets weak or changes shape in extreme temperatures.

High-Temperature Screening

If you screen hot stuff, you need mesh that can take heat. Some metal mesh works up to 450°C. Nickel-chromium alloy mesh can take even more heat, up to 1200°C. Kevlar mesh fabric stays strong in very cold places, down to -196°C.

| Material Type | Temperature Range (°C) | Notes |

|---|---|---|

| QuesTek Metal Mesh | -60 to +450 | Fatigue resistance exceeding 10^7 cycles |

| Nickel-Chromium Alloy Mesh | Up to 1200 | Exceptional heat resistance |

| Kevlar Mesh Fabric | -73 to 302 | Maintains integrity at cryogenic temperatures (-196°C) |

Pick mesh that fits your temperature needs. This keeps your mesh safe and strong.

Expansion/Contraction

Hot and cold can make mesh grow or shrink. If mesh gets hot, it can stretch and get loose. If it gets cold, it can shrink and pull tight. You need mesh that stays the same when temperatures change. This helps your screening work well and stops damage.

Note: Always tell your supplier about your temperature range. This helps you get mesh that works for your job and lasts longer.

Cut Size and Throughput

When you choose wire mesh for your screening deck, you need to think about cut size and throughput. These two factors decide how well your mesh separates materials and how much you can process in a shift.

Particle Size

You want to get the right size of material out of your screen. The mesh size controls what particles pass through and what stays on top. If you need precise separation, you should use a finer mesh. This means smaller openings in the wire mesh. Finer mesh gives you better accuracy, but you might need to slow down your feed rate. Slower feed helps you get clean separation, but it can lower your overall capacity.

If you use a larger mesh, you can move more material through your screen. Bigger openings let more particles pass, so you get higher throughput. The trade-off is that you may lose some accuracy in separation. You need to balance your need for precision with your need for speed.

Tip: Always match your wire mesh size to your target particle size. This helps you reach your quality goals and keeps your plant running smoothly.

Open Area

Open area means the total space in your wire mesh that lets material pass through. More open area means higher throughput. You can process more tons per hour if your mesh has a lot of open space. Wire mesh with thicker wires has less open area, which can slow down your screening rate.

Here’s a simple table to help you see how open area affects your operation:

| Mesh Type | Wire Diameter | Open Area (%) | Throughput Potential |

|---|---|---|---|

| Fine Mesh | Thin | High | Lower |

| Coarse Mesh | Thick | Moderate | Higher |

If you want to boost your throughput, pick wire mesh with a higher open area. Just remember, more open area can mean less strength, so you need to balance durability with performance.

Deck Tensioning

How you install and tension your wire mesh on the deck makes a big difference in how long it lasts and how well it works. Good tensioning keeps your mesh flat and tight, so you get consistent results.

Hook Types

Wire mesh screens use different hook types to attach to the deck. Common hooks include C-type, V-type, and square hooks. Each hook type fits certain deck frames and helps keep the mesh secure. If you pick the wrong hook, your mesh can slip or sag, which hurts your screening efficiency.

- C-type hooks work well for most flat deck frames.

- V-type hooks fit special tensioning rails.

- Square hooks give extra grip for heavy-duty jobs.

Always check your deck frame before you order wire mesh. The right hook type helps you install your mesh quickly and keeps it tight during operation.

Panel Fit

Panel fit means how well your wire mesh fits the deck. If your mesh is too loose or too tight, you can get problems like sagging, tearing, or poor screening. Frame-pretensioned flat screens offer a strong solution. These screens come permanently tensioned and bonded to a rigid frame. You get consistent performance and better tension retention. This setup stops your mesh from sagging or tearing, so you get longer life and better efficiency.

Regular checks during operation help you catch problems early. If you keep your wire mesh tight and secure, you avoid downtime and keep your plant running at full speed.

Note: Proper installation and tensioning of wire mesh screens are key for long service life. Always inspect your screens and tensioning system to prevent failures and keep your operation efficient.

Material vs Performance Trade-Offs

Carbon Steel vs Stainless Steel

When you pick wire mesh, you often look at carbon steel and stainless steel. Both have good and bad points. You want to know how each one works in tough places.

Carbon steel wire mesh is very strong. It can hold heavy loads. People use it in mining and aggregate plants. These places have a lot of abrasion. Carbon steel mesh does not wear out fast. But it does not do well with water. It can rust and corrode in wet or chemical spots. You need to check and fix it more often to keep it working well.

Stainless steel mesh is not the same. It has chromium in it. Chromium makes a layer that protects the mesh. This layer stops rust and corrosion. Stainless steel mesh lasts longer in wet, salty, or chemical places. People use it for recycling and wet aggregate screening. It costs more than carbon steel. But you do not need to fix it as much. It also fights corrosion better.

Here’s a table to help you see the differences:

| Property | Carbon Steel | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Susceptible to rust and corrosion | Superior due to chromium content |

| Strength | Generally stronger | Typically less strong than carbon steel |

| Cost | More cost-effective | Usually more expensive |

| Maintenance | Higher due to corrosion issues | Lower due to inherent corrosion resistance |

You should pick the mesh that fits your job. If you work in dry and rough places, carbon steel mesh works well and saves money. If you work in wet or harsh places, stainless steel mesh is better for quality and lasts longer.

Tip: Always look at your work area before you choose a screen mesh. This helps you stop problems early and keeps your plant running.

Spring Steel and Alloys

Spring steel wire mesh is very strong and flexible. You use it for heavy jobs. This mesh can bend and snap back. It takes hits from big rocks and minerals. You see spring steel mesh in mining and quarry sites. It does not wear out fast and lasts longer in tough jobs.

Alloy wire mesh types are even stronger. Some alloys have more manganese or chromium. These meshes fight wear and corrosion better than regular steel. You get better quality and longer life in hard jobs.

Spring steel mesh needs to stay tight. If you keep it tight, it works better and lasts longer. You should check your mesh often. This helps you find problems early and avoid machine stops.

Note: Spring steel and alloy mesh are best for jobs with lots of hits and rough materials. They are strong and last long, but you need to check tension and do maintenance.

Galvanized Steel Options

Galvanized steel wire mesh is a cheaper choice for less risky jobs. It has a zinc coating that stops rust. This mesh works well in building and light screening jobs. It gives you good life for less money.

But galvanized steel does not fight rust as well as stainless steel. The zinc coating can wear off over time. If you use it in wet or chemical places, it wears off faster. When the coating is gone, the mesh can rust. Stainless steel mesh has a layer that lasts longer and works better in tough spots.

If you need mesh for jobs with some water or chemicals, galvanized steel mesh is a good pick. You save money and get okay results. For tough jobs, stainless steel mesh is better for long life and quality.

Tip: Use galvanized steel mesh for dry or low-moisture jobs. If you expect a lot of water or chemicals, use stainless steel mesh for better results.

You have many wire mesh types to pick from. Each type gives you different strength, life, and price. You need to balance wear, rust resistance, and cost to get the best mesh for your job.

Balancing Wear, Corrosion, and Cost

You face tough choices when you pick wire mesh for industrial screening. You want your mesh to last, but you also need to control costs. You have to think about how much wear your mesh will see, how much corrosion it will face, and how much you can spend. Let’s break down how you can balance these three factors for mining, quarry, aggregate, recycling, and construction jobs.

Here’s a simple way to approach your decision:

- Consider the environment

Will your wire mesh work outside, inside, or in a place with chemicals? If you screen wet aggregate or recycle materials, corrosion can be a big problem. Stainless steel mesh fights rust better than carbon steel mesh. If you screen dry stone in a quarry, carbon steel mesh may be enough. - Identify the purpose

What are you screening? If you need to separate fine particles, you want mesh with small openings. If you handle heavy rocks, you need wire mesh with thick wires for strength. - Assess load requirements

Does your mesh need to handle heavy loads or just light material? Spring steel mesh works well for high-impact jobs. For lighter screening, galvanized steel mesh can save you money. - Think about coatings and treatments

You can boost the life of your wire mesh with coatings. Galvanizing adds a zinc layer to steel mesh, which helps fight corrosion. Powder coating gives mesh a tough finish, but it’s not common for heavy screening. Anodizing works for aluminum mesh, but you rarely use aluminum mesh in mining or aggregate.

If you want extra durability, ask your supplier about coatings for your wire mesh. Galvanized mesh works well for moderate corrosion. Stainless steel mesh is best for wet or chemical screening.

Let’s look at how cost fits into your decision. Cheaper mesh may seem like a good deal, but it often wears out faster. You end up replacing wire mesh more often, which means more downtime and higher costs over time. Durable mesh, like stainless steel or spring steel mesh, costs more upfront but lasts longer. You save money on replacements and keep your plant running.

Here’s a quick table to help you compare:

| Mesh Type | Wear Resistance | Corrosion Resistance | Upfront Cost | Replacement Frequency |

|---|---|---|---|---|

| Carbon Steel Mesh | High | Low | Low | High |

| Stainless Steel Mesh | Moderate | High | High | Low |

| Spring Steel Mesh | Very High | Moderate | Moderate | Low |

| Galvanized Mesh | Moderate | Moderate | Low | Moderate |

You need to match your wire mesh to your job. If you work in a wet or chemical area, stainless steel mesh is worth the extra cost. For dry, abrasive jobs, carbon steel mesh or spring steel mesh can save you money. Galvanized mesh is a good middle ground for light aggregate or construction screening.

- Choosing wire mesh with the right balance of wear resistance and corrosion resistance helps you cut costs in the long run.

- Always check your screening environment and material type before you order mesh.

- Ask about coatings if you want to extend the life of your wire mesh.

Tip: Don’t just look at the price tag. Think about how often you’ll need to replace your mesh and how much downtime you can afford. The right wire mesh keeps your operation moving and saves you money over time.

You can make smart choices by looking at your environment, your screening needs, and your budget. Wire mesh is a key part of your plant’s success. Pick mesh that fits your job, and you’ll get better results, longer wear life, and lower costs.

Wire Mesh Screens: Technical Parameters

Wire Diameter and Strength

Wire diameter is very important for wire mesh screens. Thicker wire makes the mesh stronger. Strong mesh can handle heavy loads and tough jobs. Thick wire also helps the mesh last longer. It does not break as fast under pressure or heat. If you pick the right wire diameter, your mesh works better. You will not have to fix or replace it as often. This saves you money and time.

- Thick wire gives more strength and lasts longer.

- The right wire diameter helps your mesh work well.

- If you pick the wrong wire diameter, your mesh can break early and cost more to fix.

Always match the wire diameter to your job. Mining and quarry work need strong mesh for rocks and minerals. Recycling and building jobs may need different wire thickness for their materials.

Tip: Ask your supplier which wire diameter is best for your screening deck. This helps you get mesh that is strong and lasts a long time.

Aperture Size and Cut Point

Aperture size is the opening in your wire mesh. This size decides what particles go through and what stays on top. You want the right cut point for your job. Bigger apertures let more material pass, but you lose some accuracy. Smaller apertures give better accuracy, but you process less at once.

- Bigger apertures move more material but are less exact.

- Smaller apertures are more exact but move less material.

You need to balance speed and accuracy. Mining and aggregate jobs use bigger apertures for more material. If you need fine separation, like in recycling, use smaller apertures.

Note: Always match aperture size to your target particle size. This helps you reach your quality goals and keeps your plant working well.

Open Area and Efficiency

Open area is the space in your mesh that lets material pass. The open area percentage changes how much you can process. More open area means more material can go through. This helps you work faster and screen better. More open area gives particles more chances to pass. This makes your screening more efficient.

- More open area means faster flow and more material.

- More open area helps your screening work better.

- Less open area can make mesh last longer but slows down flow.

- The open area percentage tells you how much you can process.

- More open area gives better results for filtration and screening.

- Knowing your open area helps you get the same results every time.

Always check the open area when you pick mesh screens. If you want to process more, pick mesh with more open area. If you want your mesh to last longer, pick less open area for more strength.

| Parameter | Impact on Screening | Best Use Case |

|---|---|---|

| Wire Diameter | Strength, durability | Heavy loads, abrasive jobs |

| Aperture Size | Precision, throughput | Fine or coarse separation |

| Open Area | Efficiency, flow rate | High-volume screening |

Tip: The best results come from the right mix of wire diameter, aperture size, and open area in your wire mesh screens.

Mesh Configuration and Material Choice

When you pick wire mesh screens, look at the mesh shape and the material. These two things work together. They decide how well your screening works and how long your equipment lasts.

There are a few common mesh shapes for industrial screening. Square mesh wire cloth is very popular. This mesh helps you get the right cut size. You can separate materials accurately with it. If you need exact sizes in mining or aggregate, square mesh is a good choice. Pre-crimped wire mesh is another important type. This mesh keeps its shape and handles shaking and heavy loads. It also lets small particles reach the screen fast, which makes screening work better.

You may also see slotted mesh or rectangular mesh in some jobs. Slotted mesh is good if you want to move more material and stop clogging. It works well for sticky or wet materials in recycling or building. Each mesh shape has its own strengths. You need to match the mesh to your material and your job.

The material you pick is just as important as the mesh shape. Stainless steel wire mesh screens are strong and do not rust. Use stainless steel for wet aggregate, chemicals, or tough jobs where you want the screen to last a long time. Galvanized steel mesh is cheaper and still fights rust. It is a good choice for light aggregate or building jobs where you do not expect a lot of wear or chemicals.

Here’s a quick table to help you compare:

| Mesh Configuration | Best Use Case | Material Options | Key Benefit |

|---|---|---|---|

| Square Mesh | Precise sizing, dry screening | Carbon, Stainless, Galvanized | Accurate cut size, easy cleaning |

| Pre-Crimped Mesh | Heavy loads, vibration | Carbon, Stainless | Holds shape, resists wear |

| Slotted/Rectangular | Wet/sticky material | Stainless, Galvanized | Reduces blinding, boosts throughput |

You should always think about the mesh properties and where you will use them. For example, stainless steel mesh does not rust and lasts longer in hard jobs like food or chemical screening. Galvanized mesh works well for normal jobs and helps save money.

Tip: Pick the mesh shape and material that fit your screening job. This helps you get the best results and makes your wire mesh screens last longer.

When you know the differences in mesh shape and material, you can make better choices for your plant. You will have fewer breakdowns, better screening, and lower costs.

Applications and Alternatives for High-Quality Wire Mesh

Self-Cleaning Screens

Wire mesh screens can get blocked or clogged in tough jobs. Self-cleaning screens help stop these problems. They use special mesh shapes and wires that bend. These screens shake off stuck material. This means better flow and less time fixing things. You see self-cleaning screens in mining, recycling, and mineral processing. They also work in aggregate jobs. These screens are good for sticky or wet stuff that blocks normal wire mesh.

Here’s a table that shows where self-cleaning screens work best and what they do for you:

| Application Area | Performance Benefits |

|---|---|

| Mineral Processing | Removes debris by itself, works better, needs less fixing, steady results, saves money |

| Wastewater Treatment | Removes debris by itself, works better, needs less fixing, steady results, saves money |

| Food Processing | Removes debris by itself, works better, needs less fixing, steady results, saves money |

| Aggregate Industries | Removes debris by itself, works better, needs less fixing, steady results, saves money |

| Mining | Stops clogging, handles tough stuff, screens well, uses shaking to help |

| Agriculture | Stops clogging, handles tough stuff, screens well, uses shaking to help |

| Recycling | Stops clogging, handles tough stuff, screens well, uses shaking to help |

Self-cleaning screens give you more working time and better results. They help your plant keep running and you do not need to clean them by hand as much.

PU-Mesh and Urethane Panels

PU-mesh and urethane panels are strong choices instead of wire mesh. You use these when you want your screens to last longer and be quieter. PU screens fight wear better than metal mesh. They soak up hits, so they last longer in mining and aggregate work. These screens also make less noise. PU screens can make things 15 to 20 dB(A) quieter. This keeps your team’s ears safe and helps you follow safety rules.

Here are some reasons to pick PU-mesh and urethane panels:

- PU screens last longer because they do not wear out fast and take hits well.

- You get less noise and shaking, which is good for your machines and your team.

- PU screens are good for wet or sticky jobs where metal mesh might break down.

You should use PU-mesh if you want less fixing and a safer place to work. These panels fit many screening jobs, especially when you need strong and quiet screens.

Rubber Panels and Punch Plates

Rubber panels and punch plates are other good choices for tough jobs. Rubber panels are good when you need to take big hits and stop shaking. They make your work area safer and more comfy. Punch plates can take high drops and protect the finer mesh under them. Both work well in mining, quarry, and aggregate screening.

Let’s see the good and bad points:

| Material Type | Advantages | Limitations |

|---|---|---|

| Punch Plates | Very strong, takes high drops, protects finer mesh below | Not as exact as wire mesh or PU, best for big hits |

| Rubber Panels | Takes heavy hits, stops shaking, makes things safer | Not good for small stuff, can clog with wet or odd-shaped material, less open space |

Use rubber panels for big pieces and hard jobs. They are not good for small or fine screening. Punch plates are great for big hits but are not as exact as wire mesh. Always pick the right screen for your job.

Tip: If you have heavy hits or need to protect finer mesh, rubber panels and punch plates are smart picks. For fine and exact screening, use high-quality wire mesh or PU-mesh.

You have many choices for screening jobs. Each type of mesh or panel works best for certain needs. You get better results when you match your screen to your job and work area.

Screen Accessories

When you set up your wire mesh screens, you need the right accessories to keep everything working smoothly. These parts help you install, maintain, and protect your mesh. You want your screening deck to run without trouble, so picking the best accessories matters.

You use tensioning bolts and bars to keep your wire mesh tight. If your mesh gets loose, you lose efficiency and risk damage. Tensioning systems make sure your mesh stays flat and secure. You can check tension during routine inspections. This helps you spot problems before they cause downtime.

You also need side clamps and support rails. These hold your wire mesh in place on the deck. Good clamps stop the mesh from shifting or vibrating too much. Support rails spread the load and help your mesh last longer. If you work in mining or aggregate, strong clamps and rails are a must.

Edge protectors and rubber buffers help your mesh fight wear. You place edge protectors along the sides of your wire mesh. They stop rocks and heavy material from cutting into the mesh. Rubber buffers absorb impact and reduce noise. You get a safer work area and longer mesh life.

You might use spray bars for wet screening. Spray bars wash material over your wire mesh. This keeps the mesh clean and helps prevent blinding. If you screen sticky or wet aggregate, spray bars make your job easier.

Here’s a table showing common accessories and their benefits:

| Accessory | Purpose | Benefit |

|---|---|---|

| Tensioning Bolts | Keep mesh tight | Prevents sagging, boosts life |

| Side Clamps | Hold mesh in place | Stops shifting, reduces wear |

| Support Rails | Spread load | Extends mesh lifespan |

| Edge Protectors | Guard mesh edges | Fights abrasion, saves mesh |

| Rubber Buffers | Absorb impact | Lowers noise, protects mesh |

| Spray Bars | Clean mesh during screening | Prevents blinding, improves flow |

Tip: Always check your wire mesh accessories during maintenance. If you see worn clamps or loose tensioning bolts, replace them right away. This keeps your mesh working at its best.

You can also add self-cleaning ball decks under your wire mesh. Ball decks use rubber balls that bounce and knock material loose from the mesh. This stops blinding and keeps throughput high. Ball decks work well in recycling and wet aggregate screening.

If you use modular mesh panels, you need the right connectors and locking pins. These accessories help you swap panels fast. You save time during changeouts and keep your plant running.

You should talk to your supplier about which accessories fit your wire mesh and deck type. The right setup helps you get the most out of your mesh. You avoid downtime, boost efficiency, and extend the life of your wire mesh screens.

Metal Mesh Screen Material Comparison Table

When you pick wire mesh for screening, you should compare materials. Each material has good and bad points. You want to use the right mesh for your job. This is true for mining, aggregate, recycling, or building work. Comparing helps you see which mesh fits your needs.

Material Comparison Table

| Material | Best for | Pros | Limitations | Typical applications |

|---|---|---|---|---|

| Carbon Steel | Dry, abrasive screening | High strength, cost-effective | Low corrosion resistance | Mining, aggregate, quarry |

| Stainless Steel | Wet, corrosive environments | Excellent corrosion resistance | Higher cost | Recycling, wet aggregate, chemical screening |

| Spring Steel | High-impact, heavy-duty | Superior abrasion resistance, flexibility | May require frequent tensioning | Primary scalping, heavy mining |

| Galvanized Steel | Moderate corrosion risk | Affordable, rust protection | Limited wear resistance | Construction, light aggregate |

| PU-Mesh/Urethane | Blinding, noise, impact | Long wear life, quiet operation | Higher initial cost, lower open area | Wet screening, recycling, fines removal |

Each mesh material works best for certain jobs. Carbon steel is strong and cheap for dry, rough work. Stainless steel does not rust and is good for wet or chemical places. Spring steel bends and fights wear, so it is good for heavy jobs. Galvanized steel is cheaper and stops rust, but it does not last as long in hard jobs. PU-mesh and urethane are quiet and last long, which is good for wet or sticky jobs.

Tip: Always check your work area before picking mesh. The right mesh can help your machines run longer and need less fixing.

Think about how often you will need to change your mesh. Some mesh lasts longer but costs more at first. Other mesh is cheaper but may need to be replaced more. To keep your plant running well, match the mesh to your work and what you screen.

If you are not sure which mesh or panel to use, ask your supplier. They can help you pick the best mesh for your plant and your job.

Specifying Wire Mesh Screen Material for Quotations

Material and Grade

When you want a quote for wire mesh, you must say what material and grade you need. This helps suppliers know what you want for mining, quarry, aggregate, recycling, or building jobs. You can pick from carbon steel, stainless steel, spring steel, galvanized steel, or PU-mesh. Each one is best for certain jobs. Stainless steel does not rust in wet screening. Carbon steel is good for dry, rough loads. Spring steel bends and works for jobs with lots of hits. Galvanized steel stops rust in places that are not too wet. PU-mesh is quiet and helps stop blinding.

You should also tell the supplier the grade. For example, stainless steel has grades like 304 or 316. These grades change how the mesh works in tough places. If you need special wire mesh, tell your supplier what you need it for. This helps them pick the right material and grade for your plant.

Tip: Always write down the exact material and grade you want. This stops mix-ups and makes sure you get the right wire mesh for your job.

Wire Diameter and Aperture

Wire diameter and aperture size are very important for a wire mesh quote. Wire diameter changes how strong the mesh is and how long it lasts. Thick wire lasts longer and takes heavy loads. Thin wire gives more open space and lets more material through. Aperture size decides what particles can go through. You need to match the mesh holes to the size you want to cut.

Here’s what you should tell the supplier:

- Wire diameter (in mm or inches)

- Aperture size (in mm or inches)

- Mesh count (how many holes per inch)

- Weave type (plain, twilled, or custom)

If you want a special wire mesh for a certain job, tell the supplier the size limits you need. This helps them make panels that fit your deck and do the job right. Special wire mesh may need different wire diameters or hole sizes. Always include these details in your quote.

| Parameter | Why It Matters |

|---|---|

| Wire diameter | Strength, wear life |

| Aperture size | Cut size, throughput |

| Mesh count | Separation accuracy |

| Weave type | Performance, durability |

Panel Size and Deck

Panel size and deck fit are important for putting in your mesh and making it work well. You need to tell the supplier the exact size of each wire mesh panel. Say the length, width, and thickness. If you use rolls, tell the roll width and length. This helps the supplier make mesh that fits your deck with no extra cutting.

You should also say what kind of deck you have. Some decks need flat panels. Others use panels that snap together or come in rolls. If you use wire mesh screens for noise or dust, tell the panel size and how you will put them up. Good installation starts with panels that fit your deck just right.

Note: Giving the right panel size and deck info helps you avoid problems when you install the mesh. Always check your measurements before you ask for a quote.

If you need help putting in your mesh, ask your supplier for tips. They can help you pick the best panel size for your deck and give ideas to make screening work better.

Hook Types and Edge Finish

When you buy wire mesh for screening, you must say what hook type and edge finish you want. These choices help you put in the mesh fast and keep it safe while you use it. There are different hook types, like C-type, V-type, and square hooks. Each hook works with a certain deck frame. If you pick the wrong hook, your mesh might slip or hang down. This can stop your work and make screening less good.

C-type hooks are good for flat deck frames. V-type hooks go with tensioning rails. Square hooks hold tight for heavy-duty jobs. You should look at your deck before you pick a hook type. If you use modular panels, you may need special hooks or locking pins.

Edge finish is important too. You can get welded, folded, or reinforced edges. Welded edges make the mesh stronger and stop it from coming apart. Folded edges make it easier to put in the mesh. Reinforced edges help the mesh last longer when you screen heavy rocks or minerals. If you screen tough stuff, reinforced edges can stop early damage.

Here’s a quick table to help you compare:

| Hook Type | Best Use Case | Edge Finish | Benefit |

|---|---|---|---|

| C-type | Flat deck frames | Welded/Folded | Easy install, strong hold |

| V-type | Tensioning rails | Welded | Secure fit, less sagging |

| Square | Heavy-duty decks | Reinforced | Extra grip, long life |

Tip: Always match your hook type and edge finish to your deck and screening job. This keeps your wire mesh tight and helps it last longer.

Application Details

When you ask for a quote for wire mesh, you should give clear details about your job. This helps the maker know what you need and send the right mesh. If you share good details, you get a quote that fits your needs and no surprises.

You should tell them:

- The material you want to screen, like rock, ore, or recycled stuff

- How wet or hot your work area is

- The size and shape of the pieces you want to separate

- How much you want to screen each hour or shift

- The deck size and model of your screening machine

Giving this information helps the supplier know what work is needed. They can plan how to make and send your mesh. You get a quote that covers everything, from mesh type to how you will put it in.

Here’s why sharing details matters:

- Makers know your needs better

- They can see exactly what your screening job is

- They plan how to make and ship your mesh

- You get a quote that covers all parts of your order

If you forget details, you might get mesh that does not fit or breaks in your work area. This can cause more stops and cost more money. Always give as much information as you can when you ask for a quote.

Note: The more details you give, the better your wire mesh quote will be. This helps you avoid delays and keeps your plant working well.

Conclusion

Choosing wire mesh that truly fits your job starts with the right specification—material, surface treatment, aperture (hole size), wire diameter, and proper tensioning. These factors directly impact screening accuracy, throughput, and service life in industrial operations.

As a manufacturer of industrial wire screens and woven wire mesh with over 20 years of experience, ANPENG provides custom-built screen media and technical support for mining, quarry & aggregate, recycling, and construction applications. Tell us what you’re screening and share your target cut size, moisture level, capacity/throughput, and screen model/deck dimensions—we’ll recommend the best specification and provide a fast quotation.

FAQ

What is the best wire mesh for mining applications?

You should use heavy-duty wire mesh made from spring steel or carbon steel. These materials handle abrasion and impact from rocks. They last longer in mining and quarry screening jobs.

How do I choose mesh size for aggregate screening?

Pick mesh size based on your target particle size. Smaller mesh openings give you finer separation. Larger mesh lets more material through. Always match mesh size to your screening goals.

Can wire mesh resist corrosion in wet environments?

Stainless steel wire mesh works best in wet or chemical screening. It resists rust and corrosion. If you screen wet aggregate or recycled materials, stainless steel mesh gives you longer service life.

What are the benefits of PU-mesh panels?

PU-mesh panels reduce noise and last longer in high-impact jobs. They help prevent blinding and work well for wet screening. You get quieter operation and less downtime with PU-mesh.

How often should I replace wire mesh screens?

Check your wire mesh regularly for wear or damage. Replace mesh when you see holes, sagging, or reduced efficiency. Using the right mesh material helps you extend replacement intervals.

What hook type should I use for my screening deck?

Choose hook type based on your deck frame. C-type hooks fit flat decks. V-type hooks work with tensioning rails. Square hooks hold heavy wire mesh for tough screening jobs.

How do I prevent mesh blinding during screening?

Use self-cleaning wire mesh or PU-mesh panels. These designs shake off stuck material. You keep throughput high and reduce manual cleaning in mining, aggregate, and recycling plants.

Can I get custom wire mesh for my screen model?

Yes, you can order custom wire mesh panels. Provide your deck size, mesh material, wire diameter, and aperture size. ANPENG supplies mesh tailored for industrial screening machines.