You use urethane screen panels when you need tough screening media for vibrating screens. These panels help you sort materials by size. This makes processing faster in mining, quarry, aggregate, recycling, construction, mineral processing, and dewatering. These panels last longer than old wire screens. They do not wear out or clog easily.

Key Takeaways

- Urethane screen panels are strong and last longer than wire screens. This makes them good for hard jobs.

- These panels help lower downtime and maintenance costs. They do this because they resist wear and have a modular design.

- Urethane panels work well with wet and sticky materials. They stop clogging and keep things running smoothly.

- They also help reduce noise, so the work area is quieter than with metal screens.

- Picking the right panel size and thickness is very important. This helps the panels work best for the material you use.

- Urethane screen panels can be used in many industries. Some examples are mining, recycling, and construction.

- Urethane panels may cost more at first. But they save money later by needing fewer repairs and replacements.

- Always make sure the panels fit your screening system. This helps avoid problems with setup and how well they work.

Urethane Screen Panels Overview

What Are Urethane Screen Panels

Urethane screen panels are used in many industries. They help sort and separate materials by size. You find them in vibrating screens for mining, aggregate, recycling, and construction. The panels are made from polyurethane mesh. This mesh gives special qualities. You get strong panels that bend and resist chemicals. These features help the panels last longer and work better than older ones.

Here’s a quick look at what makes polyurethane screen panels special:

| Property | Description |

|---|---|

| Durability | Panels last longer and need less fixing. |

| Noise Reduction | They make less noise, which helps in quiet places. |

| Chemical Resistance | Panels stand up to many chemicals, so you can use them anywhere. |

| Flexibility | Polyurethane mesh lets you shape panels for better sorting. |

| Wear Resistance | Panels do not wear out fast, even in tough jobs. |

| High Tensile Strength | Panels can handle stress during screening. |

| Reduced Blinding and Pegging | Polyurethane mesh keeps material moving and stops clogging. |

| Versatility | You can change panels for different jobs. |

You use these panels for sorting, filtering, and separating materials. Polyurethane mesh helps you do hard jobs better.

How They Work in Screening Systems

Polyurethane screen panels make sorting and sieving easier. Vibrating screens use these panels to separate materials by size. The panels shake to move particles. Fast shaking moves small pieces through the mesh. Big shakes push larger pieces along. This helps sort materials quickly.

Here’s how polyurethane screen panels help you:

- Panels shake to sort materials by size.

- Polyurethane mesh lets small pieces pass and holds big ones.

- Panels are strong, so materials move smoothly and rarely clog.

- You get fewer stops and save money on repairs.

- Panels last longer, so you fix them less often.

You use these panels for sorting, sieving, and filtering. Polyurethane mesh helps you finish work faster and with less trouble.

Comparison to Other Media

You may wonder how polyurethane screen panels compare to other types. Let’s see how they match up with steel wire screens and rubber screens.

- Polyurethane screen panels last two to three times longer than steel screens.

- In iron ore jobs, polyurethane mesh panels last about 22 months. Steel screens only last 4.3 months.

- Polyurethane mesh lets materials flow 20 to 30 percent better than steel wire screens.

- You get less clogging with polyurethane mesh, so sorting stays easy.

- Rubber screens wear out in 3 to 4 months. Steel mesh lasts 1.5 to 2.5 months. Polyurethane mesh panels last 12 to 18 months.

Here’s a table to show the difference:

| Material | Average Lifespan (Months) |

|---|---|

| PU Screen Mesh | 12-18 |

| Rubber Screens | 3-4 |

| Steel Woven Mesh | 1.5-2.5 |

Tip: If you want panels that last longer and sort better, pick polyurethane mesh panels for your screens.

Polyurethane screen panels give you better wear resistance, longer life, and better sorting. You get more value and less downtime. Polyurethane mesh panels help your screening jobs run smoothly.

Polyurethane Screen Panels Manufacturing

Molding and Casting Process

You may wonder how companies make strong polyurethane screen panels. The process starts with careful planning and simple steps. Here is what usually happens:

- Developing the Master Pattern

First, you need a detailed CAD model. This model helps you make a master pattern. You use 3D printing or CNC machines for this. The pattern must be exact so the panel fits well. - Choosing and Mixing the Silicone

Next, you pick the right silicone rubber for the mold. The choice depends on how long you want the mold to last. It also depends on how well it works with urethane resins. You mix the silicone slowly to get a smooth, strong mold. - Finalizing the Urethane Cast

Then, you blend the polyurethane resin and pour it in the mold. Vacuum degassing takes out bubbles. This makes the panel solid and even. It helps your screen panel stay strong.

Tip: If you want panels that last longer, make sure vacuum degassing is used. This keeps the panels strong and free of air pockets.

Reinforcement Features

Polyurethane screen panels need extra strength for heavy loads. Companies add special features to make them stronger. Here are some common ways:

| Feature Description | Source |

|---|---|

| High strength polyurethane coating and wear-resistant surface; reinforcement bars parallel to panel width | Polyurethane Modular Screens |

| Metal hooked edges connected with steel wires; covered by polyurethane elastomers | Polyurethane Screens |

| Well-designed screen distributes load evenly; proper tensioning and reinforcement elements enhance durability | The Ultimate Guide to Polyurethane Screen Mesh |

You get panels with metal edges, steel wires, and tough coatings. These features help your panels last longer and work better under pressure.

Quality and Durability

You want screen panels that can handle tough jobs. Companies test each panel to make sure it is good. They use special tools and methods to check for problems and measure strength.

| Test Method | Description | Key Findings |

|---|---|---|

| Automated Vision Systems | High-res cameras check aperture sizes | Fewer size defects—22% less than manual checks |

| Laser Profilometry | 3D maps spot thickness changes | Panels with less than 2% deviation last 31% longer |

| Ultrasonic Testing | Finds hidden voids inside panels | Defective screens fail at 45% lower load capacities |

| Dynamic Load Testing | Checks resistance to loads and abrasion | ASTM-standard screens keep 90% throughput after 18 months |

You get panels that pass tough tests. These panels resist wear, keep their shape, and last through hard use. When you pick polyurethane screen panels, you choose a product made for strength and reliability.

Key Benefits of Urethane Screen Panels

Abrasion and Impact Resistance

You want your screening panels to last a long time. Urethane screen panels are tough and protect against damage. When rocks or minerals hit them, they do not wear out quickly. These panels keep working even when the job is hard. Experts use special tests to check how well these panels resist abrasion:

| Test Method | Description |

|---|---|

| ASTM D1630 | Measures two-body abrasion using a footwear abrader. |

| ASTM D5963 | Measures two-body abrasion using a rotary drum abrader. |

| ASTM G65 | Measures three-body abrasion using a dry sand/rubber wheel apparatus. |

| ASTM G105 | Measures three-body abrasion using wet sand/rubber wheel tests. |

These tests show that urethane screen panels can handle heavy use. They keep their shape and stay strong. If you work with rough materials like quartz sand or iron ore, these panels last much longer than rubber screens. They also do not break or crack easily. You will spend less time fixing screens and more time working.

Tip: Urethane screen panels help you work faster. You do not need to change panels as often.

Corrosion and Chemical Resistance

Sometimes you work in places with chemicals or water. Urethane screen panels do not get damaged by these things easily. You can use them in wet or dirty places without worry.

Here are some facts about their chemical resistance:

- Polyester polyurethanes do not get ruined by oils, fuels, or solvents.

- Polyether polyurethanes can handle water and hydrolysis.

- Special additives make them stronger against acids, alkalis, and oxidation.

- Very strong acids or alkalis can still cause damage over time.

These panels keep working even when chemicals are around. You do not have to replace them often. Your screening system stays strong and reliable.

Anti-Clogging and Noise Reduction

It is annoying when screens clog or make loud noises. Urethane screen panels help stop both problems. Their design keeps materials moving and stops sticky stuff from blocking the mesh.

Check out these features that help prevent clogging:

| Feature | Description |

|---|---|

| Hydrophobic Coatings | Stops water from soaking in and mold from growing. Works well in wet places. |

| Sealed Edges | Keeps water out so the panel keeps its shape. |

| Relaxation Screening Mechanism | Separates wet or sticky materials without clogging. Keeps the work going. |

| Anti-Corrosive Properties | Stops damage from water and makes panels last longer. |

These panels work well even with wet or sticky materials. They do not clog, so you finish jobs faster.

Noise is another problem with screens. Urethane screen panels are much quieter than metal ones. The material is soft and absorbs hits, so there is less noise. You get a quieter place to work and your equipment lasts longer because there is less shaking.

Note: If you want better results and less noise, urethane screen panels are a smart pick.

Modular Replacement

You want your screening system to run smoothly. Urethane screen panels make that easier with modular replacement. This means you can swap out just one panel at a time instead of changing the whole screen. You save time and money because you do not need to stop everything for a big repair.

Here’s why modular replacement helps you:

- You can replace individual panels quickly. You do not need to take apart the whole deck.

- You spend less on screen replacement costs. You only buy what you need.

- You get less downtime during maintenance. Your team gets back to work faster.

- You reduce hazards. You do not need to handle heavy frames or large sections.

- You keep your system running at top speed. You fix problems before they slow you down.

Let’s say one panel wears out or gets damaged. You just pop it out and put in a new one. The rest of your screen keeps working. You do not waste time waiting for a full replacement. This design makes your job safer and easier.

Tip: If you want to boost your maintenance efficiency, choose modular urethane screen panels. You will spend less time fixing and more time producing.

Modular replacement gives you control. You decide when and where to make changes. Your screening system stays strong and reliable. You get more value from every panel.

Limitations and Trade-Offs

Temperature and Sizing Limits

Urethane screen panels do not work everywhere. Heat can change how well they work. Most polyurethane screens can take short heat up to 80–90°C (176–194°F). For long use, keep them at 60–70°C (140–158°F). Some special screens, like Derrick’s Polyweb, can handle 126°C (260°F). But most brands cannot do this. Thicker panels are better with heat than thin ones. If your workspace has good airflow, panels stay cooler and last longer. Bad airflow can make them too hot and break.

Size is also important. Polyurethane screen plates cannot always be very big. If you need a huge or special-shaped screen, you may have trouble. These panels are best for normal sizes and shapes. If your job needs a special size, you might need something else.

- Most panels can take 80–90°C for a short time.

- Long use is safest at 60–70°C.

- Thicker panels are better with heat.

- Good airflow helps panels last longer.

- Very big or custom screens may not be possible.

Tip: Always check the heat and size you need before you pick urethane panels.

Upfront Cost vs Service Life

Urethane screen panels cost more when you buy them. The price is about 25–35% higher than other screens. This can be hard for small businesses. You may wonder if the higher price is worth it. The good news is these panels last much longer. They help you avoid surprise repairs. You can cut downtime by 60%. Most companies get their money back in 18–24 months. Over five years, you could save 140–160% compared to cheaper screens.

- Urethane panels cost more at first.

- Small businesses may think the price is high.

- Panels last longer and cut downtime.

- You usually get your money back in less than two years.

- Five-year savings can be very big.

Note: If you want fewer repairs and more savings, urethane panels are a smart choice.

System Compatibility

Switching to urethane screen panels can be tricky. You need to make sure they fit your system. Sometimes, different materials grow or shrink when it gets hot or cold. This can cause stress and damage. Water is another problem. If you do not control water, mold can grow or panels can break down. Chemicals in your system can also hurt the panels. This can cause color changes or damage.

Here are some common problems:

| Compatibility Issue | Description |

|---|---|

| Thermal Expansion and Contraction | Different materials grow and shrink at different rates. This can cause stress. |

| Moisture Management | Bad water control can cause mold or damage. |

| Chemical Compatibility | Some chemicals can hurt the panels or change their color. |

You should always check your system before you put in new panels. Make sure everything works together. This helps you avoid problems and keeps your screening system working well.

Tip: Talk to your supplier about your system. They can help you pick panels that fit and last.

Polyurethane Screen Panels Applications

Mining and Mineral Processing

Polyurethane screen panels are used a lot in mining. These panels sort rocks, minerals, and ores by size. Mining and quarrying need screens that can handle heavy loads. Polyurethane panels do not wear out fast from sharp stones. You do not need to replace them often, so your team works more. In mineral processing, these panels separate good minerals from waste. They work well with wet or sticky materials. You do not worry about chemicals or rust hurting the screens. If you want to work better in mining, these panels are a good choice.

Quarry and Aggregate

Quarrying and aggregate jobs need strong screens. Polyurethane screen panels sort gravel, sand, and crushed stone. These panels last longer than steel wire screens. You do not hear loud sounds because polyurethane absorbs shaking. The panels stay strong and do not break, even when work gets rough. Polyurethane panels help stop clogging and blinding. Materials move easily through the mesh. You clean less and make more. With a lifespan up to ten times longer than wire screens, you save money on repairs and work. Your aggregate jobs go faster and smoother. You get good results every day.

Tip: If you want to save money and keep your quarry working, use polyurethane screen panels.

| Feature | Benefit for Quarrying and Aggregate |

|---|---|

| Abrasion Resistance | Handles sharp stones and sand |

| Low Noise | Quieter work environment |

| Flexible Structure | Reduces clogging and blinding |

| Long Lifespan | Fewer replacements needed |

Recycling and Construction

Polyurethane screen panels are used in recycling and construction. These panels help separate plastics, metals, and other waste. You finish jobs faster because the screens work well. Polyurethane panels are tough, so you do not replace them often. Here are some reasons these panels are good for recycling and construction: You spend less money on fixing and running the screens. The panels sort materials better for recycling. You can handle waste with chemicals or dirt. The screens are flexible and can be changed for different jobs. You work in a quieter place with less shaking. If you want your recycling to be greener and faster, polyurethane screen panels are a smart pick. You get better sorting and a safer place to work.

Note: Polyurethane panels help you do hard jobs in recycling and construction. You get more value and less trouble.

Dewatering and Classification

Polyurethane screen panels are used a lot for dewatering and classification. These panels help separate water from solids. You get cleaner and drier materials. In mineral processing or construction, you need screens that last. Polyurethane panels are strong and do not break down easily. They resist wear and corrosion, so rust and damage are not a problem.

The panels are very elastic. They bend and flex but do not crack. This lets them handle heavy loads and fast water. The panels clean themselves, so they do not clog. Wet and sticky materials move through the mesh easily. You spend less time cleaning and more time working.

Many companies use GN Polyurethane Screen Panels for these jobs. These panels are very durable. You get great screening efficiency. The mesh lets water go through but holds solids back. You can sort sand, gravel, minerals, and other things quickly. The panels keep working even when the job is hard.

Here’s how polyurethane screen panels help with dewatering and classification:

- You get drier products with less water left.

- The panels last longer, so you replace them less.

- You see fewer clogs and less downtime.

- The mesh sorts materials by size for better results.

If you want to improve your screening system, polyurethane screen panels make work easier. You get strong panels that keep your job moving.

Wastewater Treatment

Polyurethane screen panels are used in wastewater treatment plants. These panels help clean water and remove unwanted particles. The panels stand up to tough chemicals and rough materials. They do not break down or lose their shape.

- Chemical Resistance: Polyurethane panels handle many chemicals in wastewater. You do not worry about damage or losing function.

- Abrasion Resistance: The panels deal with rough particles. You get screens that last in harsh conditions.

- Precision Filtration: Fine mesh separates small particles and contaminants. You meet rules and keep water clean.

Polyurethane screen panels need little maintenance. You do not spend much time fixing or replacing them. The panels work well with changing water flow. They handle biological materials without trouble. You save money and keep your plant running well.

If you want screens that last and help you follow strict rules, polyurethane panels are a smart choice. You get clean water, reliable performance, and less hassle.

Polyurethane Screen Panel Types

Square and Slotted Openings

You have two main choices when it comes to the shape of the openings in your polyurethane screen panels: square and slotted. Each type works best for different jobs.

- Slotted openings help you move more material through the screen. They let you handle higher loads and keep things flowing. You will notice less plugging and blinding, which means fewer stops to clear out stuck material.

- Square openings give you better accuracy. If you need to separate particles by size with precision, square holes do the job well. They help you get clean, even results.

Here’s a quick comparison:

| Opening Type | Best For | Key Benefit |

|---|---|---|

| Square | Precise particle separation | High screening efficiency |

| Slotted (Rectangular) | High throughput, wet or sticky materials | Less clogging, more flow |

Tip: If you want speed and less clogging, go with slotted. If you need exact sizing, square openings are your best bet.

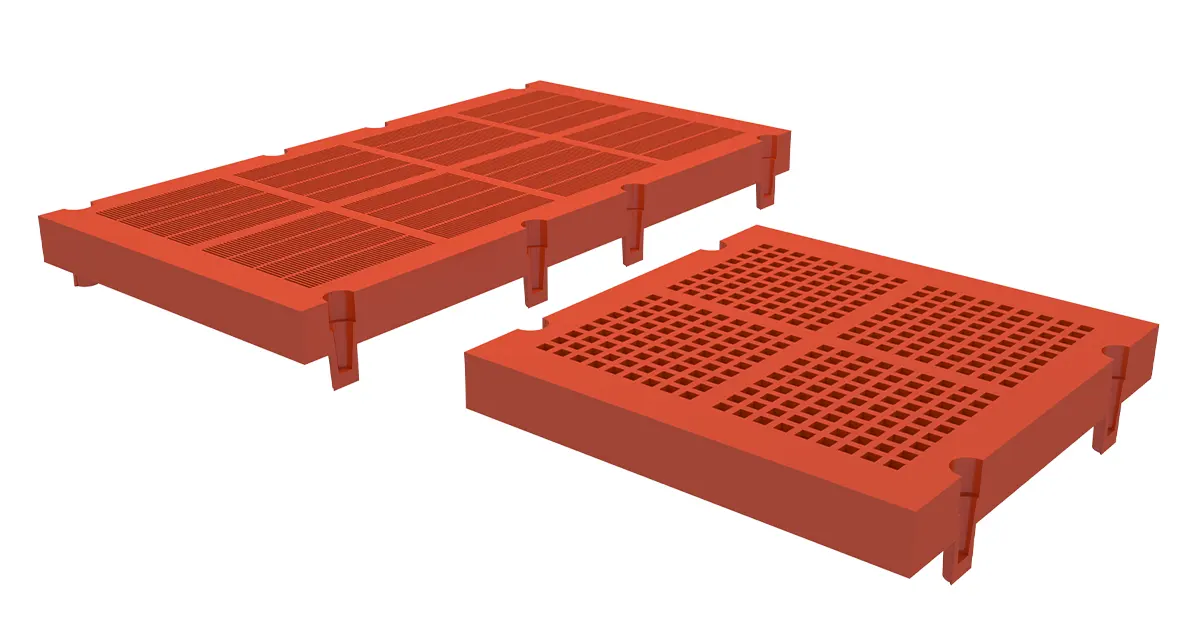

Modular Formats

Modular polyurethane screen panels make your life easier. You can install and replace them one at a time. You do not have to change the whole screen when only one part wears out. This saves you time and money.

- You can swap out just the worn panels. No need to replace the whole deck.

- These panels are light and easy to handle. You do not need special tools or pins.

- Polyurethane screens last much longer than wire screens. You spend less on repairs and labor.

- The flexible design helps stop clogging and blinding. You keep working without many breaks.

Modular panels also help you store fewer spares on-site. You only keep what you need. When you need to fix something, you do it fast and get back to work. This design keeps your team safe and your job running smoothly.

Note: Modular panels help you finish maintenance quickly. You spend more time producing and less time fixing.

Fastening and Edge Options

You want your screen panels to stay in place, even when the job gets tough. Polyurethane screen panels come with strong edge and fastening options. Many panels use a mix of high-quality polyurethane and metal. This combo gives you a tight seal and a secure fit.

The strong edges protect the panel from damage. They also help keep the panel stable, so it does not move or shift during use. This means your panels last longer and work better, even in rough conditions.

If you work in a tough environment, these edge options give you peace of mind. Your panels stay put, and you do not have to worry about leaks or breaks.

Tip: Choose panels with reinforced edges and secure fastening for the best stability and longer service life.

Installation and Maintenance

Fastening Methods

You want your urethane screen panels to stay secure during tough jobs. Picking the right fastening method makes installation easier and keeps your panels in place. Here’s a quick look at the most common ways to fasten these panels:

| Method Type | Specifications/Tools | Steps |

|---|---|---|

| Expansion Nail Type | 305×305×30 (four semi-circular holes) | 1. Place the screen on the support beam. 2. Align expansion nail holes. 3. Hammer nails vertically into holes. |

| Bolt Type | M12, M14, M16 | 1. Arrange screens on the support beam. 2. Align mounting holes. 3. Secure with tension bolts. |

| Rail Seat Type | Manufacturer-specific rail seats | 1. Fix rail seats to the support beam. 2. Align screen grooves with rail seat protrusions. 3. Ensure firm placement. |

You can use expansion nails for a quick fit. Bolts give you a strong hold. Rail seats work well for modular panels. Each method helps you keep your panels tight and steady, even when the screen shakes hard.

Tip: Always check the manufacturer’s instructions before you start. Using the right tools and steps helps you avoid problems later.

Safety Tips

Safety matters every time you install or maintain screen panels. You want to protect yourself and your team. Here are some simple tips to keep everyone safe:

- Wear gloves and safety glasses when handling panels and tools.

- Make sure the vibrating screen is turned off and locked out before you start work.

- Use the right lifting gear for heavy panels. Don’t try to lift big panels alone.

- Check for sharp edges or loose bolts before you touch the screen.

- Keep your workspace clean to avoid slips and trips.

Note: Taking a few minutes for safety checks can save you from injuries and costly mistakes.

Maintenance Practices

You want your urethane screen panels to last as long as possible. Good maintenance keeps your screens working and saves you money. Here are some easy ways to care for your panels:

- Clean the panels every day after shutdown. Remove debris so the load stays balanced.

- Look for signs of wear like thinning, cracks, or impact marks during routine checks.

- Inspect the screen frame before you install new panels. Fix any damage to make sure the foundation is solid.

- Follow proper installation and maintenance steps. This helps your panels last longer and work better.

Tip: Regular cleaning and inspection help you spot problems early. You spend less time fixing screens and more time getting the job done.

Taking care of your screen panels is simple. You just need to follow a few steps and stay alert. Your panels will keep working hard, and your team will stay safe.

Choosing the Right Urethane Screen Panel

Material and Abrasion Needs

Picking the right urethane screen panel starts with knowing what you need for your job. You want to think about the type of material you will screen. Is it sharp, heavy, or soft? Some materials wear out screens faster than others. If you work with rocks, gravel, or minerals, you need panels that can handle a lot of wear and tear.

Here are some things you should look at:

- Know your screening application. Think about the size of the material, how wet it is, how rough it feels, and how much you need to process.

- Check the abrasiveness of your material. If your material is very rough, pick panels with high wear resistance.

- If you deal with big, heavy pieces, choose panels with strong impact resistance.

- Look at the panel thickness and size. Thicker panels last longer with tough jobs.

- Think about how easy it is to install and maintain the panels. Modular designs help you swap out panels fast.

- Make sure the panel fits your machine and works with your setup.

You want panels that last a long time and keep your work moving. If you pick the right panel, you spend less time fixing and more time getting the job done.

Moisture and Throughput

Moisture can change how your screen works. Wet materials can stick to the mesh and slow things down. If you work with wet or sticky materials, pick panels with special coatings or slotted openings. These features help keep the material moving and stop clogging.

Throughput is how much material you can process in a certain time. You want to keep your throughput high so you finish jobs faster. The right panel design helps you move more material through the screen. If you want to improve throughput, look for panels with larger or slotted openings. These let more material pass and keep your system running smoothly.

- Wet materials need panels that resist clogging.

- Slotted openings help move more material and keep throughput high.

- Special coatings can help with sticky or wet jobs.

- Always match your panel to the moisture level and the amount of material you need to process.

Tip: If you want to keep your work fast and easy, always check how moisture and throughput affect your screen choice.

Cut Size and Panel Thickness

Cut size means the size of the holes in your screen panel. You pick the cut size based on how small or large you want your final product. If you need fine material, choose panels with small holes. For bigger pieces, go with larger holes.

Panel thickness also matters. Thicker panels last longer, especially with rough or heavy materials. But if you need very fine screening, thinner panels might work better. Always balance the need for durability with the need for accuracy.

Here’s a quick guide:

| Need | Best Choice |

|---|---|

| Fine screening | Small cut size, thin panel |

| Heavy, rough material | Large cut size, thick panel |

| High throughput | Slotted openings, right thickness |

Choosing the right cut size and panel thickness helps you get the results you want. You keep your system working well and avoid extra repairs.

Deck Compatibility

You want your urethane screen panels to fit your screening deck perfectly. If the panels do not match your deck, you will face problems like loose panels, poor screening, or even damage to your equipment. Deck compatibility means making sure your new panels work with your current screen frame and support system.

Start by checking the type of deck you have. Most vibrating screens use one of these deck types:

- Flat Decks: These are simple and common. You lay the panels flat across the frame.

- Crowned Decks: These decks have a slight curve. The curve helps materials move to the sides and keeps the panels tight.

- Modular Decks: These use small, replaceable panels. You can swap out just one panel if it wears out.

You should always measure your deck before you order new panels. Look at the length, width, and thickness. Check the spacing between support beams. If you use modular panels, count how many fit across and down your deck.

Here’s a quick checklist to help you:

- Measure the deck size and shape.

- Check the support beam spacing.

- Count the number of panels needed.

- Look at the fastening system (bolts, rails, or nails).

- Make sure the panel thickness matches your deck’s capacity.

Tip: If you are not sure about your deck type, take a photo and ask your supplier. They can help you pick the right panels.

Some decks need special fastening systems. For example, rail seats or bolt holes must line up with your deck. If you get this wrong, the panels will not stay in place. Always match the fastening method to your deck.

Here’s a table to show common deck types and the best panel options:

| Deck Type | Best Panel Format | Fastening Method |

|---|---|---|

| Flat | Large or modular | Bolts, expansion nails |

| Crowned | Flexible modular | Rail seats, bolts |

| Modular | Small modular panels | Snap-in, rail seats |

You want your screening system to run smoothly. When your panels fit your deck, you get better screening, less downtime, and longer panel life. If you ever upgrade your deck, check compatibility again before you buy new panels.

Note: Always double-check your deck specs before you order. The right fit saves you time, money, and headaches.

Alternatives to Urethane Panels

When you look for screening media, you have more choices than just urethane panels. You might want something different for your job. Let’s check out some popular alternatives. Each one has its own strengths and weaknesses.

Woven Wire Screens

Woven wire screens are classic. You see them in many plants and quarries. These screens use metal wires woven together to make a mesh. You get sharp cut sizes and fast material flow.

Why pick woven wire screens?

- You get high open area for quick screening.

- You can choose from many wire diameters and opening sizes.

- You swap out panels fast when they wear out.

But you should know about the downsides. Woven wire screens wear out quickly. Sharp rocks and heavy loads can break wires. You might need to replace them often. They also make more noise than polyurethane panels.

| Feature | Woven Wire Screens |

|---|---|

| Lifespan | Short |

| Noise Level | High |

| Cost | Low |

| Clogging | Common |

Tip: If you want a low-cost option and don’t mind frequent changes, woven wire screens might work for you.

Self-Cleaning Screens

Self-cleaning screens help you fight clogging and blinding. These screens use special wires or flexible mesh. The wires move and shake, so sticky material falls off. You get steady performance, even with wet or sticky jobs.

What makes self-cleaning screens special?

- You see less downtime from clogging.

- You keep throughput high with tough materials.

- You get better screening in wet conditions.

Self-cleaning screens cost more than woven wire. They may not last as long as polyurethane panels. You need to check if your system fits these screens.

Note: If you deal with sticky or wet material, self-cleaning screens can save you time and trouble.

PU Mesh Screens

PU mesh screens use polyurethane like urethane panels, but they come in a mesh format. You get many of the same benefits: long life, strong wear resistance, and less noise. PU mesh screens work well for fine screening and high-impact jobs.

Why choose PU mesh screens?

- You get great abrasion resistance.

- You see less clogging and blinding.

- You enjoy quieter operation.

PU mesh screens cost more upfront. You need to make sure they fit your deck and fastening system. They work best when you want durability and low maintenance.

| Feature | PU Mesh Screens |

|---|---|

| Lifespan | Long |

| Noise Level | Low |

| Cost | High |

| Clogging | Rare |

Tip: If you want screens that last and keep your plant quiet, PU mesh screens are a smart pick.

You have choices. Think about your job, your budget, and your system. Pick the screen that helps you work faster and smarter.

Screening Media Comparison Table

You have a lot of choices when it comes to screening media. Picking the right one can make your job easier and save you money. Let’s look at how the main types stack up against each other. This table shows you the key features, so you can see which one fits your needs best.

| Feature | Urethane Screen Panels | Woven Wire Screens | Self-Cleaning Screens | PU Mesh Screens |

|---|---|---|---|---|

| Lifespan | Long (12–18 months) | Short (1.5–2.5 months) | Medium (6–10 months) | Long (12–18 months) |

| Wear Resistance | Excellent | Fair | Good | Excellent |

| Noise Level | Low | High | Medium | Low |

| Clogging/Blinding | Rare | Common | Rare | Rare |

| Upfront Cost | High | Low | Medium | High |

| Maintenance | Easy (modular) | Frequent | Moderate | Easy (modular) |

| Chemical Resistance | High | Low | Medium | High |

| Screening Accuracy | Good | Excellent | Good | Good |

| Throughput | High | High | High | High |

| Best For | Heavy-duty, wet, sticky, abrasive jobs | Fast swaps, low cost | Sticky/wet material | Fine screening, quiet operation |

Tip: If you want screens that last and need less fixing, urethane and PU mesh panels are your best bet. You get less downtime and more work done.

Quick Facts About Each Media

- Urethane Screen Panels

You get tough panels that handle rough jobs. They last long and resist chemicals. You spend less time on repairs. - Woven Wire Screens

You swap these out fast. They cost less, but you replace them often. They work well for dry, easy jobs. - Self-Cleaning Screens

You fight clogging with these. They work great with sticky or wet material. You pay a bit more, but you get steady performance. - PU Mesh Screens

You enjoy quiet work and long life. These screens resist wear and chemicals. They work best for fine screening and tough jobs.

How to Use This Table

You can use this table to match your job to the right screen. Think about what matters most. Do you want long life? Is noise a problem? Are you working with sticky or wet material? Pick the media that checks your boxes.

Note: If you still feel unsure, talk to your supplier. They can help you choose the best screen for your plant.

Guide

- Urethane/PU Mesh: Best for durability and quiet work.

- Woven Wire: Good for quick swaps and low cost.

- Self-Cleaning: Great for sticky jobs.

You have the facts. Now you can pick the right screening media and keep your plant running strong!

Conclusion

You now know why urethane screen panels work so well for sorting and filtering. They last longer, resist damage, and help you handle tough jobs. You might face limits with heat or size, but you get more value and less downtime. ANPENG makes panels for every application. Want a quote? Just tell us your material, cut size, moisture, throughput, screen model, and deck dimension.

FAQ

What makes urethane screen panels better than wire screens?

You get longer life and less clogging with urethane panels. They resist wear and chemicals. You also hear less noise during work. If you want fewer repairs and smoother jobs, urethane panels are a smart pick.

Can I use urethane screen panels for wet materials?

Yes, you can. Urethane panels work well with wet or sticky materials. The mesh design helps stop clogging. You keep your system running and finish jobs faster.

How do I know which panel opening size to choose?

Think about the size you want for your final product. For fine material, pick small openings. For bigger pieces, choose larger holes. If you feel unsure, ask your supplier for advice.

Are urethane screen panels hard to install?

No, you can install them easily. Most panels use simple fastening methods like bolts, nails, or rail seats. You can swap out one panel at a time. You do not need special tools.

How long do urethane screen panels last?

You can expect 12 to 18 months of service in most jobs. Some panels last even longer with good care. You spend less time and money on replacements.

Do urethane panels handle chemicals and high temperatures?

Urethane panels resist many chemicals. They work well in tough environments. Most panels handle temperatures up to 80–90°C for short periods. For higher heat, ask your supplier about special options.

Can I replace just one panel, or do I need to change the whole deck?

You can replace one panel at a time. Modular designs let you swap out only the worn or damaged panels. You save time and money during maintenance.

What should I check before ordering new panels?

Measure your deck size and check the fastening method. Know your material type and moisture level. Tell your supplier about your screening needs. This helps you get the right panels for your job.