You may ask what is PU mesh and why it is important for factories. PU mesh screen is made from polyurethane and features steel wire inside to enhance its strength. This polyurethane mesh is tough, bends easily, and has a long lifespan. You can find PU mesh in industries such as mining, building, aggregate, and recycling. These sectors require strong mesh screens that can support heavy loads and perform well in challenging environments. What is PU mesh? It is special because it does not wear out quickly. It is robust and continues to function effectively even in demanding conditions.

Key Takeaways

- PU mesh screens use polyurethane and steel wire. This makes them strong and flexible.

- These screens last much longer than regular wire mesh. You do not need to replace them as often.

- PU mesh works well in many industries. Some examples are mining, recycling, and aggregate processing.

- The mesh design helps stop clogging. It sorts materials well, even if they are wet.

- Polyurethane mesh absorbs vibrations. This makes the work area quieter.

- You can customize these screens. You can pick hole sizes and panel thicknesses for your needs.

- Picking the right PU mesh helps work run better. It also means less downtime.

- Buying PU mesh screens saves money over time. It also makes the workplace safer.

What Is PU Mesh?

PU Mesh Definition

You may wonder what pu mesh is and why it matters. PU mesh means polyurethane mesh. It is used in many factories. You see this mesh in places like mines and recycling plants. The mesh is made from polyurethane. Polyurethane is strong and bends easily. Factories make polyurethane mesh by casting or molding. This lets them change how hard or soft the mesh is. They can also make it resist scratches.

Here’s why polyurethane mesh is special:

- The mesh helps sort different-sized pieces. Small bits go through the holes. Big pieces stay on top.

- Polyurethane mesh does not wear out fast.

- The mesh stays bendy, even in tough places.

- Polyurethane mesh does not get damaged by chemicals.

If you ask what pu mesh is, here is a simple answer. It is a screen made from polyurethane. It helps you sort things quickly and easily.

How PU Mesh Works

Let’s see how polyurethane mesh does its job. You put the mesh inside a vibrating screen. The screen shakes and the mesh moves too. As stuff goes over the mesh, small pieces fall through the holes. Big pieces stay on top and move forward.

Polyurethane mesh panels help you sort better. You get better results than with regular screens. Polyurethane mesh lasts much longer than other types. The mesh can hold heavy loads without breaking. It also makes less noise because it absorbs shakes.

Here are some reasons to use polyurethane mesh:

- The mesh does not get blocked often. You spend less time fixing it.

- Polyurethane mesh works well when things are wet. You can sort stuff with water or oil.

- The mesh does not rust, even with chemicals.

- The mesh design stops blockages, so it works smoothly.

When you ask what pu mesh is, you learn it is more than a screen. Polyurethane mesh helps you work faster and safer with fewer problems.

Types of PU Mesh

You can pick from different kinds of polyurethane mesh. The mesh comes in many shapes and sizes. Some mesh panels have square holes. Others have slotted or round holes. You choose the type based on what you want to sort.

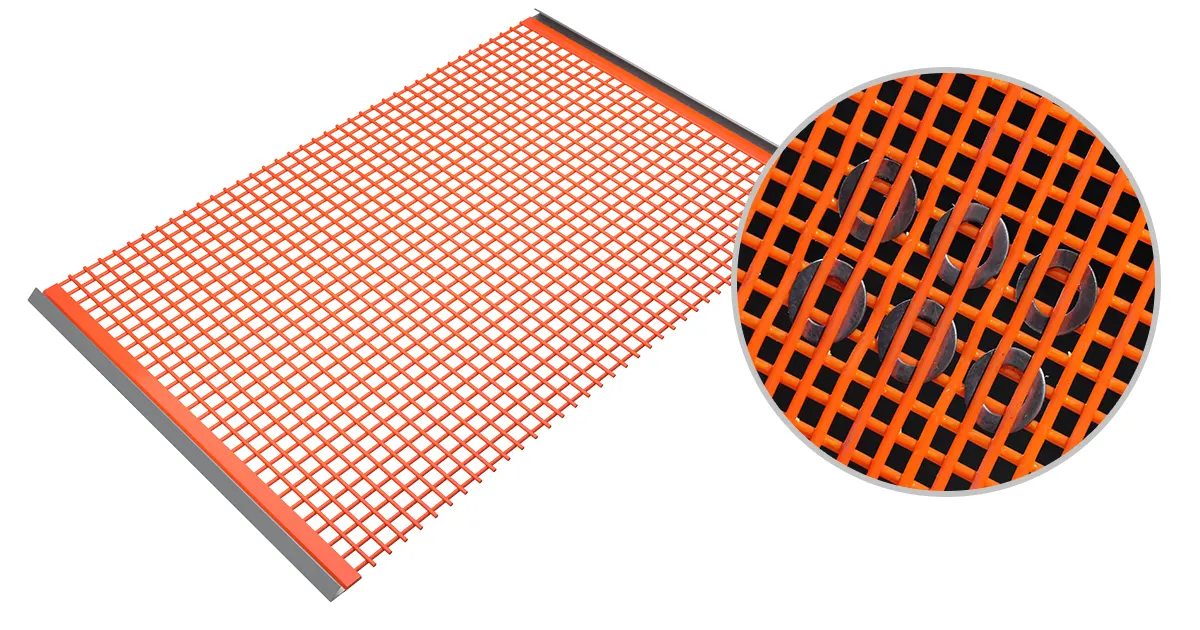

Polyurethane mesh panels can be flat or curved. Some panels snap into place, so you can change them quickly. Some mesh panels have steel wire inside for extra strength. You also pick how thick and hard the mesh is for your job.

Here’s a quick list of common types:

- Square aperture polyurethane mesh for general sorting

- Slotted mesh for sticky or wet stuff

- Heavy-duty mesh with steel wire for hard jobs

- Modular mesh panels for fast changes

No matter which type you choose, polyurethane mesh gives you a strong and lasting screen. When you ask what pu mesh is, you find a flexible tool for mining, quarry, aggregate, and recycling.

PU Mesh Composition

Polyurethane Elastomer

When you see polyurethane mesh, you notice it is very tough. Polyurethane is the main part of this mesh. Factories use polyurethane because it is a strong elastomer. This means it can stretch and bend without breaking. The mesh can hold heavy things and take rough use. Polyurethane does not scratch easily and lasts a long time. You can use polyurethane mesh where there is dust, water, or chemicals. The way polyurethane mesh is made makes it great for mining and recycling. You do not need to worry about rust or corrosion. Polyurethane mesh keeps working even when things get dirty.

Steel Wire Reinforcement

Polyurethane mesh gets stronger with steel wire inside. Makers put steel wire in the mesh when they make it. The wire works like a skeleton. It gives the mesh more support and keeps it from bending too much. You can use polyurethane mesh for hard jobs because of the steel wire. The mesh keeps its shape, even with a lot of weight on it. Look at the table below to see how steel wire helps:

| Feature | Description |

|---|---|

| Steel-Reinforced Structure | Steel wire skeleton and strong polyurethane elastomers give high strength and stop bending, so the mesh can hold heavy loads and work in tough places. |

| Extended Service Life | Lasts 8–10 times longer than metal screens and 3 times longer than stainless steel, so you do not need to replace it often. |

You get more use from polyurethane mesh with steel wire. The mesh lasts longer and saves money on new screens.

Additives and Customization

You can change how polyurethane mesh is made to fit your needs. Factories add special things to make the mesh harder or softer. You can choose the hole size, thickness, and hardness. Some polyurethane mesh panels have big holes for large rocks. Others have small holes for fine sand. You pick what works best for your job. Polyurethane mesh comes in many shapes and sizes. You can ask for custom mesh panels if you need something special. This makes polyurethane mesh a smart choice for many jobs.

Tip: If you want a mesh that lasts longer and works better, ask about custom polyurethane mesh. You can get the right kind for your job.

PU Mesh Manufacturing

Molding Process

You might wonder how factories make strong and flexible PU mesh screens. The process uses both skill and special machines. Here’s how it usually goes:

- First, workers prepare the raw materials. They pick the right additives and fillers, then clean the polyurethane resins to remove any dirt or unwanted bits.

- Next, they mix the polyurethane resin and inject it into custom molds. These molds shape the mesh panels under high pressure.

- After molding, workers cut and trim the panels. They remove any extra material and make sure each panel has the right size and shape.

- Then, they treat the surface. Sometimes, they add coatings or textures to make the mesh last longer and work better.

- Each panel goes through a quality check. Workers look for any problems and test the mesh to make sure it is strong.

- Finally, they pack the finished panels carefully so they arrive safely at your site.

This step-by-step process helps you get mesh screens that are tough and ready for hard jobs.

Aperture Formation

Getting the holes in your mesh just right is very important. Factories use high-precision molds to control the size and shape of each opening. These molds also set the thickness of the panel. By keeping tight control over the mold details, manufacturers make sure every polyurethane mesh panel fits perfectly. They also watch the temperature and how fast they inject the resin. This careful control helps the polyurethane set properly and keeps the mesh from breaking or peeling apart. You get a screen that works the same way every time.

Tip: Consistent aperture size means you can trust your mesh to sort materials accurately, batch after batch.

Quality Control

You want your mesh screens to last and perform well. That’s why factories use strict quality control at every step. Here’s a look at some of the checks they use:

| Quality Control Measure | Description |

|---|---|

| Material Quality Checks | Only high-grade, traceable metals go into the mesh to stop early failure. |

| Wire Diameter Consistency | Workers check wire thickness often to keep strength and uniformity. |

| Mesh Size Accuracy | They measure mesh spacing to make sure it works for sorting and filtering. |

| Rigorous Product Testing | Each panel gets tested for strength and checked for defects before it leaves the factory. |

These steps help you get reliable polyurethane mesh screens that stand up to tough work. You can count on each panel to do its job, shift after shift.

Key Properties

Wear Resistance

If you want a screen that lasts, choose polyurethane mesh. Polyurethane mesh stands out in tough jobs. It does not wear down fast. The mesh keeps its shape and stays strong. This is true even after many hours of work. In a lab test, polyurethane mesh lasted longer than wire mesh. The test checked how much material wore away after 1000 hours. Polyurethane mesh lost less material than wire mesh. You do not need to replace screens as often. This saves you money and time. Polyurethane mesh is great for mining, quarry, and recycling. You can trust these properties to keep your work going.

Impact and Flexibility

Heavy rocks hit your screen every day. You need a screen that can take hits. Polyurethane mesh absorbs shocks well. The flexibility lets the mesh bend and bounce back. You do not see cracks or breaks. The mesh goes back to its shape after each hit. Here is how different screens compare:

- Polyurethane screens are very impact resistant and flexible. You can use them for hard jobs.

- Woven wire mesh breaks more easily when hit hard. It does not bend much.

- Urethane panels bend a little, but not as much as polyurethane mesh.

- Polyurethane screens spread out the force, so they do not get damaged.

- Woven wire mesh can snap because the wires are thin.

- Urethane panels do not last as long or absorb hits as well as polyurethane mesh.

- Polyurethane mesh lasts two to three times longer than steel screens. This is because it bends and absorbs impacts.

You get more use from your screen with polyurethane mesh. The flexibility means fewer repairs and less downtime. These properties make your work safer and easier.

Noise and Corrosion Resistance

Factories and mines can be loud places. You want a quieter workspace. Polyurethane mesh helps lower noise. The mesh absorbs shakes, so your screen does not rattle much. You hear less banging and clanging. This makes your job easier and safer. Polyurethane also protects your mesh from rust and chemicals. You do not have to worry about water or harsh stuff. Polyurethane mesh does not rust like metal screens. The wear resistance and flexibility keep your mesh working. This is true even in wet or dirty places. You get a screen that lasts longer and works better.

Tip: If you want a screen that is quiet and does not rust, pick polyurethane mesh. Its special properties make it the best choice for hard jobs.

Limitations

PU mesh screens offer many benefits, but you should know about their limits before you choose them for your job. No screen is perfect for every situation. Here are some things you might want to consider:

- Higher Initial Cost

You may notice that PU mesh screens cost more than regular wire mesh at first. The price comes from the special materials and the way factories make them. If you have a tight budget, this can be a big factor. Over time, PU mesh can save you money because it lasts longer, but you need to plan for the upfront cost. - Temperature Sensitivity

Polyurethane does not like very high heat. If your work area gets hotter than 80°C (about 176°F), PU mesh can start to soften or lose its shape. In places with extreme heat, metal screens might work better. You should check the temperature where you want to use the mesh. - Chemical Compatibility

PU mesh resists many chemicals, but not all. Some strong acids, solvents, or oils can damage the mesh. If you use harsh chemicals in your process, you need to ask your supplier if PU mesh will hold up. You do not want your screen to break down in the middle of a job. - Aperture Size Limits

Factories can make PU mesh with many hole sizes, but there are limits. Very fine or very large holes can be hard to produce. If you need a special size, you might have to wait longer or pay more. Sometimes, wire mesh gives you more options for tiny or huge openings. - Weight and Handling

PU mesh panels can be heavier than wire mesh, especially with steel wire inside. You may need more people or special tools to move and install them. This can slow down your work if you change screens often.

Note:Always talk to your supplier about your needs. Tell them about your material, temperature, and chemicals. They can help you pick the right screen and avoid problems.

Here’s a quick table to help you see the main limits:

| Limitation | What You Should Know |

|---|---|

| Higher Cost | Costs more at first than wire mesh |

| Heat Sensitivity | Not good for very hot jobs |

| Chemical Limits | Some chemicals can damage PU mesh |

| Aperture Range | Not always available in every hole size |

| Weight | Can be heavier and harder to handle |

You can see that PU mesh screens work great in many places, but you need to check if they fit your job. Knowing these limits helps you make a smart choice and avoid surprises.

Applications

Quarry & Aggregate

You see polyurethane mesh used in many quarry and aggregate applications. When you work with rocks, gravel, or sand, you need a tough screen that can handle heavy loads. Polyurethane mesh gives you that strength. You get a screen that lasts longer and works better than regular wire mesh.

In a quarry, you want to sort materials fast. Polyurethane mesh helps you do this. The mesh does not clog easily, so you spend less time cleaning and more time working. You notice that the mesh keeps its shape, even when big rocks hit it. This means you get steady results every day.

Let’s look at how polyurethane mesh compares to other screens in quarry and aggregate applications:

| Feature | Wire Mesh (hours) | Synthetic Media (hours) |

|---|---|---|

| Typical Wear Life | 300 – 600 | 2,000 – 5,000 |

| Screening Capacity Impact | Minimal reduction | Increased capacity possible due to less clogging |

You can see that polyurethane mesh lasts much longer than wire mesh. You do not have to change your screen as often. This saves you money and keeps your work moving. The mesh also helps you sort more material because it does not block up. You get higher capacity and better results.

Polyurethane mesh works well in wet or dry conditions. You can use it for many applications, like sorting gravel, crushed stone, or sand. The mesh resists wear and does not rust, so you can trust it in harsh environments. You find that polyurethane mesh is easy to install and replace. You can choose different mesh sizes for your applications, so you get the right fit for your job.

Tip: If you want a screen that lasts longer and helps you sort more material, try polyurethane mesh in your quarry or aggregate applications.

Polyurethane mesh gives you a strong, flexible screen for many applications. You get better performance, less downtime, and more value from your equipment.

Other Industrial Uses

You might think PU mesh screens only fit mining, quarry, or recycling jobs. That’s not true. You can find these screens in many other industrial applications. If you work in a factory or plant, you probably need to sort, wash, or process materials. PU mesh screens help you do that faster and safer.

Let’s look at some common applications outside of mining and quarry work. You see PU mesh screens in aggregate processing. These screens sort rocks, sand, and gravel. You get clean and uniform materials for your next step. Washing applications also use PU mesh screens. When you need to rinse or clean materials, the mesh lets water flow through while holding back the solids. You spend less time cleaning and more time working.

Cement manufacturing is another big area for PU mesh screens. You need to separate fine powders from larger chunks. The mesh stands up to heavy use and does not wear out quickly. You get steady results and fewer breakdowns. PU mesh screens also resist chemicals found in cement plants. You do not worry about rust or corrosion.

Here’s a quick table to show you some other industrial applications for PU mesh screens:

| Application Area |

|---|

| Aggregate Processing |

| Washing Applications |

| Cement Manufacturing |

You can see that PU mesh screens fit many applications. If you run a plant, you want equipment that lasts. PU mesh screens give you that. You get strong panels that handle tough jobs. The mesh does not clog easily, so you keep your line moving.

Some factories use PU mesh screens for food processing. You sort grains, seeds, or beans. The mesh keeps your product clean and safe. You also find PU mesh screens in chemical plants. The mesh stands up to harsh liquids and powders. You get reliable performance in every batch.

You might use PU mesh screens in water treatment applications. The mesh helps filter out solids and keeps your system running smoothly. You save time on maintenance because the mesh does not block up. You get more uptime and better results.

If you need custom applications, you can ask for special mesh sizes or shapes. PU mesh screens adapt to your needs. You get panels that fit your machines and your process. The flexibility of PU mesh screens means you can use them in almost any industrial job.

Tip: If you want to improve your plant’s efficiency, try PU mesh screens in new applications. You might find they solve problems you did not expect.

PU mesh screens give you options. You get strong, flexible, and long-lasting panels for many industrial applications. Whether you sort, wash, or filter, PU mesh screens help you work better.

PU Mesh vs Other Media

Woven Wire Comparison

You might wonder how polyurethane mesh stacks up against woven wire. Woven wire screens have been around for a long time. They are easy to find and cost less at first. You can use them for many jobs, especially when you need fine sorting. But woven wire screens wear out fast. They break when heavy rocks hit them. You spend more time changing screens and fixing problems. Woven wire screens also make a lot of noise. If you work in a loud place, this can be a big issue. Polyurethane mesh lasts much longer. It bends without breaking and handles tough jobs. You get less downtime and a quieter workspace.

Urethane Panel Comparison

You may also see urethane panels used for screening. Urethane panels are strong and resist chemicals. They work well in wet or dirty places. But they do not have as much open area as polyurethane mesh. This means you sort less material at once. Urethane panels can be heavy and hard to install. Polyurethane mesh is lighter and easier to handle. You get better screening efficiency because the mesh has more open space. Polyurethane mesh also reduces noise more than urethane panels. If you want a screen that works fast and lasts long, polyurethane mesh is a smart choice.

Performance Table

Let’s look at how polyurethane mesh, woven wire, and urethane panels compare. This table shows you the main differences:

| Feature | PU Mesh Screen | Woven Wire Screen | Urethane Panel Screen |

|---|---|---|---|

| Screening Efficiency | 70–85% open area, high throughput | Good for fine sorting, lower open area | Lower open area, slower sorting |

| Wear Resistance | Lasts 1.5–3x longer than rubber, resists abrasion | Wears out fast, needs frequent replacement | Good, but not as long as PU mesh |

| Weight | Light, easy to install | Lightest, easy to handle | Heavy, harder to move |

| Chemical Resistance | Stable in harsh environments | Can rust, not good with chemicals | Good resistance, but less than PU mesh |

| Noise Levels | Reduces noise by 10–15 dB | Loud, can be unsafe | Some noise reduction |

| Cost | Higher upfront cost, saves money over time | Cheapest, but needs more replacements | Moderate, but less efficient |

Tip: If you want a screen that lasts longer, sorts faster, and keeps your workplace quiet, polyurethane mesh is a great option. You may pay more at first, but you save time and money in the long run.

You can see that polyurethane mesh gives you better performance in most jobs. Woven wire screens work for simple tasks, but they wear out quickly. Urethane panels resist chemicals, but they do not sort as fast. Polyurethane mesh stands out for its strength, flexibility, and efficiency. You get a screen that works hard and keeps your operation running smoothly.

How to Choose PU Mesh

Aperture Size

When you pick a screen for your job, aperture size matters a lot. The holes in your polyurethane screen panel decide what gets through and what stays on top. If you choose the right size, you boost your screening efficiency and get more material sorted in less time. Small holes work best for fine particles. Large holes let bigger pieces pass through. You need to match the aperture size to your material.

Take a look at this table. It shows how aperture size can change your results:

| What Happens on the Screen Deck | What It Means for You |

|---|---|

| Different shapes and sizes affect screening performance | Picking the right aperture size improves efficiency |

| More particle bounces on polyurethane than steel | You get better movement and higher throughput |

| Layers of mixed sizes build up on the deck | The right aperture size helps control material flow |

| Low feed rates cause bigger bounces on rubber decks | Good aperture size keeps particles moving efficiently |

If you want your screen to work well, always think about the size and shape of the holes. The right choice helps you sort faster and keeps your operation running smoothly.

Thickness & Hardness

You also need to look at thickness and hardness when choosing a polyurethane screen panel. These features decide how tough your screen is and how long it lasts. Thicker panels stand up to heavy loads and rough materials. Hardness tells you how much the screen can bend before it breaks.

Factories use special formulas to make screens that last longer. For example, they use imported MDI to boost abrasion resistance. Most screens have a hardness of Shore A 90±2. This gives you a good mix of durability and flexibility. If you work with sharp rocks or heavy material, pick a thicker and harder screen. If you need more flexibility, go for a softer panel.

Here’s a quick table to help you decide:

| Specification | Details |

|---|---|

| Wear-Resistant Formula | Imported MDI for better abrasion resistance |

| Hardness | Shore A 90±2 for balance and flexibility |

Choosing the right thickness and hardness means your screen will last longer and handle tough jobs without trouble.

Panel Size & Fixing

Panel size and fixing methods make a big difference in how easy it is to install and maintain your screen. If you pick the right size, you save time during setup and replacement. Modular panels let you swap out only the damaged sections. This reduces downtime and saves money.

You have several fixing options. You can use bolt-on, hold-down pin, clamp down, or clip-on methods. Each one fits different machines and jobs. Proper installation can extend the life of your polyurethane screen panel by over 40%. When you follow best practices, you keep your operation running and avoid costly delays.

Here’s a list of things to remember:

- Modular panels allow quick replacement and less downtime.

- Choose a fixing method that matches your equipment.

- Good installation boosts screen life and efficiency.

If you want your screen to last and work well, pay attention to panel size and fixing. The right setup helps you get the most out of your polyurethane screen panel.

Material & Throughput

When you pick a PU mesh screen, you need to think about the material you want to screen and how much you want to process. Not all materials act the same way on a screen. Some are dry and flow easily. Others are wet, sticky, or heavy. If you know your material, you can choose the right mesh and get better results.

Here are some things you should look at:

- Particle size distribution: Check if your material has big chunks, fine dust, or a mix. The size of the particles will help you pick the right aperture.

- Moisture content: Wet material can stick to the mesh and block the holes. If your material is damp, you may need a special mesh design.

- Bulk density: Heavy materials put more stress on the screen. You might need a thicker or reinforced mesh for these jobs.

- Type and weight of material: Some materials are sharp or abrasive. Others are soft. The type and weight will affect how long your mesh lasts.

- Surface moisture: If your material has water on the surface, it can change how it moves across the screen. Wet surfaces may need a different mesh shape or size.

- Gradation of feed material: If your feed has a wide range of sizes, you may need a mesh that can handle both big and small pieces.

Throughput is just as important. You want to know how much material you need to screen every hour. This is called tons per hour (TPH). If you need to process a lot, you should pick a mesh with a bigger open area. This lets more material pass through and keeps your operation moving.

- Maximum tons per hour: Know your target. If you need high throughput, choose a mesh that can handle the load.

- Desired size of separation: Decide what size you want to separate. This helps you pick the right aperture.

- Screening accuracy: Some jobs need very precise sorting. Others just need to separate big from small. Pick your mesh based on how accurate you need to be.

- Special operation requirements: Sometimes you have unique needs, like handling hot material or chemicals. Make sure your mesh can handle these conditions.

Tip: Always match your PU mesh screen to your material and throughput needs. This helps you get the best performance and longest life from your screen.

Selection Checklist

You want to make sure you get the right PU mesh screen for your job. Use this checklist to help you cover all the important points before you buy:

| Item | Description |

|---|---|

| Overall dimensions | Measure your screen deck for a perfect fit. |

| Mesh type | Pick the right mesh for your material and screening needs. |

| Aperture size | Choose the hole size based on your desired separation. |

| Thickness & hardness | Select the right thickness and hardness for your material load. |

| Panel size & fixing | Make sure the panel size and fixing method match your equipment. |

| Throughput (TPH) | Check that the mesh can handle your required tons per hour. |

| Material characteristics | Think about particle size, moisture, and bulk density. |

| Special requirements | Note any unique needs, like chemical resistance or high temperature. |

Note: If you follow this checklist, you can pick a PU mesh screen that fits your job, lasts longer, and keeps your operation running smoothly.

Benefits & Advantages

Service Life

You want your screen panels to last a long time. Polyurethane mesh screens help with this. These screens are strong and work well for tough jobs. They keep working for many months. Look at this table to see how long they last:

| Screen Type | Average Service Life (Months) | Comparison to Woven Wire Panels |

|---|---|---|

| PU Mesh Screens | 6 to 12 | 10 to 15 times longer |

| Woven Wire Panels | 0.4 to 1.2 | Baseline |

Polyurethane mesh screens last much longer than woven wire. You do not need to change them as often. This means you can spend more time working. If you use steel core polyurethane mesh, it lasts even longer. These screens last 8 to 10 times longer than stainless steel wire mesh. You can trust your equipment to keep running.

Cost Efficiency

Every business wants to save money. Polyurethane mesh screens help you do this in many ways. You do not need to buy new screens as often. This saves you money on repairs and downtime. When your screens last longer, your machines work better. You can sort more material without stopping often.

Here are some ways polyurethane mesh screens help you save:

- You change screens less, so you pay less for maintenance.

- Less downtime means your machines keep working.

- You can process more material faster.

- The screens do not wear out quickly, so you save money.

Tip: If you want your equipment to work better and cost less, pick polyurethane mesh screens. You will be more efficient and save money.

Safety & Environment

Safety and the environment are important. Polyurethane mesh screens make your workplace safer. These screens lower noise and vibration. Your plant is quieter. Workers are safer from loud sounds and flying pieces. Polyurethane does not rust or break easily. This means fewer sharp edges and less danger.

Factories now use greener polyurethane materials. These are better for the environment but still work well. Studies show these screens last as long as regular ones. You can choose these screens to help the planet.

Note: Polyurethane mesh screens protect your workers and the earth. You get strong screens and good results while making a smart choice.

Conclusion

PU mesh screens are made with polyurethane and steel wire. This makes the panels strong and flexible. They last a long time. You can use these screens in mining, quarry, aggregate, and recycling. They help lower noise and improve sorting accuracy. You also save money over time. Here are the main reasons people choose PU mesh:

| Advantage | Why It Matters |

|---|---|

| High strength | Handles heavy loads and impact |

| Long service life | Lasts 8–10 times longer |

| Wide applications | Fits many machines and materials |

| High accuracy | Sorts materials with precision |

| Low noise | Makes your workplace quieter |

| Economic benefits | Saves money over time |

If you want a screen that works well and lasts, try ANPENG polyurethane mesh. Contact us to learn more or get a price!

FAQ

What is the main use of PU mesh screens?

You use PU mesh screens to sort and separate materials in mining, quarry, aggregate, and recycling. These screens help you get clean and uniform products fast.

How long does a PU mesh screen last?

PU mesh screens last much longer than wire mesh. You can expect them to work for 6 to 12 months, sometimes even more, depending on your job and material.

Can PU mesh screens handle wet materials?

Yes! You can use PU mesh screens with wet, sticky, or dirty materials. The mesh resists clogging and keeps working, even when things get messy.

Are PU mesh screens easy to install?

You find PU mesh screens easy to install. Many panels use modular designs or clip-on systems. You can swap them out quickly and get back to work.

Do PU mesh screens reduce noise?

Absolutely! PU mesh screens absorb vibration and lower noise levels. Your workspace gets quieter, and you help protect your hearing.

Can I get custom sizes or shapes?

You can order PU mesh screens in many sizes, shapes, and hole patterns. Just tell your supplier what you need for your job.

Are PU mesh screens safe for workers?

PU mesh screens help keep your workplace safe. They do not rust or break easily. You see fewer sharp edges and less risk of injury.

What should I check before buying PU mesh screens?

Check your material type, desired hole size, panel thickness, and fixing method. Make sure the screen fits your machine and handles your workload.