When you look at woven wire mesh price, several factors affect what you pay. These include material type, mesh size, wire diameter, weave pattern, and the manufacturing process.

Understanding these factors affecting price helps you spot trends and make smart buying decisions. You can plan ahead, compare suppliers, and get the best value for your industrial screening needs.

Key Takeaways

- The kind of material changes the price a lot. Stainless steel lasts longer but costs more than plain carbon steel.

- Mesh size and opening decide what can go through. Smaller mesh catches tiny things but costs more money.

- Wire diameter changes how strong and pricey it is. Thick wires are stronger but cost more. Thin wires are cheaper for light jobs.

- Weave patterns like plain, twill, and Dutch change how it works and what it costs. Pick the pattern that matches what you need.

- How it is made changes the price. Machines make it cheaper. Custom orders cost more because they need extra work.

- Buying a lot at once can make each piece cheaper. Plan ahead to get better prices for big orders.

- Extra things like coatings and edge treatments make it last longer. These extras can make the mesh cost more.

- Picking a good supplier means you get better quality. Check for certifications to make sure they meet standards.

Key Factors Affecting Woven Wire Mesh Price

Material Type And Grade

When you start looking at woven wire mesh for industrial screening, the first thing you notice is the material. The type and grade of metal you choose have a big impact on cost and performance. Stainless steel (like 304 or 316) is popular because it resists rust and lasts a long time. Sometimes, you might need something different. Nickel, plain carbon steel, aluminum, hastelloy, and inconel are all options. Each one comes with its own price tag and set of benefits.

- Stainless steel works well for most jobs, but it costs more than plain steel.

- Specialty alloys like hastelloy or inconel handle tough chemicals or high heat, but they raise the price even more.

- If you only need basic screening, plain carbon steel or aluminum might save you money.

You should always match the material to your application. This helps you avoid paying for features you don’t need.

Mesh Size And Opening

Mesh size and opening are all about how big the holes are in your wire mesh. These details decide what gets through and what stays out. Mesh size means how many openings you get per inch. Opening size (or aperture) tells you how wide each gap is.

- A fine mesh with tiny openings catches small particles but costs more to make.

- A coarse mesh with bigger openings is cheaper and lets larger items pass through.

The true value of a wire mesh product lies in its combination of quality, durability, and performance across a wide range of applications.

When you pick the right mesh size and opening, you get the best results for your screening job. You also control the woven wire mesh price because finer meshes use more material and take more time to produce.

Wire Diameter

Wire diameter is the thickness of each wire in the mesh. This detail matters a lot for both strength and cost.

- Thicker wires make the mesh stronger and heavier, but they use more metal. This pushes up the price and the weight.

- Thinner wires cost less and work well for light-duty jobs.

- If you choose a wire that’s thicker than you need, you pay extra for no reason.

You can save money by picking the minimum wire diameter that still does the job. This keeps your mesh strong enough without wasting material.

Here’s a quick look at how these factors compare:

| Factor | What It Affects | Cost Impact | Example Use Case |

|---|---|---|---|

| Material Type & Grade | Durability, corrosion | High for specialty | Food processing, mining |

| Mesh Size & Opening | Particle size, flow rate | Higher for fine mesh | Sand screening, filtration |

| Wire Diameter | Strength, weight | Higher for thick | Heavy-duty screening |

Choosing the right mix of these factors helps you get the best value for your woven wire mesh.

Weave Pattern

When you choose woven wire mesh, the weave pattern makes a big difference in how the mesh works and how much it costs. The weave pattern is the way the wires cross over and under each other. You can pick from several common patterns, and each one has its own strengths.

- Plain weave is the most basic. Each wire goes over one and under one. This pattern gives you a flat surface and even openings. It works well for most screening jobs and usually costs less.

- Twill weave lets each wire go over two and under two. This makes the mesh stronger and more flexible. You might use twill weave if you need to handle heavy loads or fine particles.

- Dutch weave uses thicker wires in one direction and thinner wires in the other. This pattern creates very small openings, which is great for filtration but can raise the price.

Tip: If you need a special pattern for your job, custom weaves are possible. Just remember, the more complex the weave, the higher the woven wire mesh price.

You should always match the weave pattern to your application. For example, plain weave works for sand screening, while Dutch weave fits fine filtration in chemical plants. Picking the right pattern helps you get the best results without paying for features you do not need.

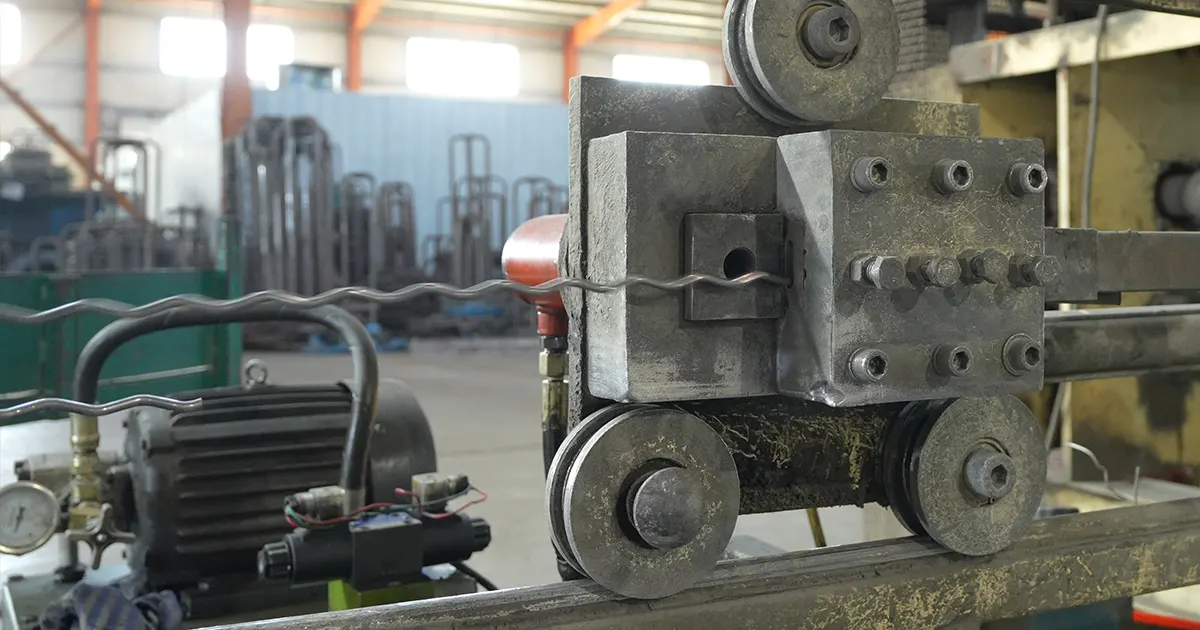

Manufacturing Process

The way manufacturers make woven wire mesh also affects the price you pay. The process starts by interlacing long wires (warp) and cross wires (weft) in a criss-cross pattern. This method creates a strong and flexible mesh with uniform openings.

Here’s what happens during production:

- Automated machines weave the wires together. This helps keep the mesh flat and the openings even.

- Different weaving techniques can make the mesh stronger or more flexible. Newer machines can work faster and make better quality mesh.

- If you need a special weave or a custom size, the process takes more time and skill. This can increase the cost.

You might notice that high-quality woven wire mesh has very precise openings. This precision comes from careful weaving and good machines. When you need mesh for tough jobs, like mining or chemical processing, you want this kind of quality.

A quick look at how the process impacts cost:

| Manufacturing Factor | Impact on Price | Why It Matters |

|---|---|---|

| Automated weaving | Lowers cost | Makes production faster and cheaper |

| Custom or complex weaves | Raises cost | Needs more time and skill |

| High raw material prices | Raises cost | Metal prices can change often |

If you want to save money, choose standard patterns and sizes. If your job needs something special, be ready to pay a bit more for the extra work. The manufacturing process shapes both the quality and the woven wire mesh price.

Material Choices And Their Impact On Price

Stainless Steel Vs. High-Carbon Steel

When you pick a material for your wire mesh, you usually start with stainless steel or high-carbon steel. Stainless steel stands out because it resists rust and handles tough environments. You see it a lot in food processing, chemical plants, and places where water or moisture is a problem. High-carbon steel, on the other hand, gives you strength at a lower cost. It works well for heavy-duty screening, like in mining or construction, but it can rust if you do not protect it.

Here’s a quick comparison:

| Material | Strength | Corrosion Resistance | Typical Use | Price Level |

|---|---|---|---|---|

| Stainless Steel | High | Excellent | Food, chemicals, outdoors | Higher |

| High-Carbon Steel | Very High | Low | Mining, dry screening | Lower |

If you need a mesh that lasts a long time and stays clean, stainless steel is worth the extra money. If you want to save on costs and do not need rust protection, high-carbon steel is a smart choice.

Specialty Alloys

Sometimes, your job needs more than just the basics. Specialty alloys like Monel, Inconel, or Hastelloy step in when you face extreme heat, strong chemicals, or saltwater. These materials handle things that would break down regular steel. For example, Inconel stands up to high temperatures in furnaces, while Monel resists seawater in marine screens.

Specialty alloys give you top performance, but they also push up the woven wire mesh price. You should only choose them if your application truly demands it. Otherwise, you might pay for features you never use.

Tip: Always match the alloy to your real-world needs. Over-specifying can waste your budget.

Raw Material Costs

Material costs change all the time. In 2023, stainless steel prices jumped by more than 18%. Aluminum and brass wire mesh also saw price swings because of shortages and shipping delays. Many manufacturers, especially smaller ones in Asia and South America, said buying materials was their biggest challenge. Supply chain problems, like crowded ports and the effects of the pandemic, made it even harder. Sometimes, orders took longer to arrive, and about one in four shipments faced delays.

This kind of price unpredictability makes it tough to plan big orders or lock in a good deal. If you buy in bulk, you might see your costs go up or down without warning. That’s why it helps to keep an eye on the market and talk with your supplier about timing.

When you understand how material choices and market trends affect your costs, you can make smarter decisions and get the best value for your project.

Mesh Specifications And Cost

Mesh Count And Aperture Size

When you choose woven wire mesh, you will see numbers like “mesh count” and “aperture size.” Mesh count tells you how many openings fit in one inch of mesh. Aperture size means the width of each opening. These two details shape how your mesh works and how much you pay.

- Higher mesh counts mean more wires and smaller holes. This makes the mesh better for catching tiny particles, but it also uses more material and takes longer to make.

- Lower mesh counts have bigger holes and fewer wires. These are cheaper and let bigger items pass through.

Aperture size matters for performance, too. If the holes are too big, unwanted particles slip through. If the holes are too small, the mesh can clog or slow down your process. You want to match the mesh count and aperture size to your job for the best results.

- The size of the holes decides what gets filtered or blocked.

- Bigger holes help with airflow and visibility.

- Smaller holes work best for fine filtration.

Tip: Picking the right mesh count and aperture size helps you balance performance and costs.

Wire Diameter Selection

Wire diameter is the thickness of each wire in your mesh. This choice affects both how strong your mesh is and how much you spend. Thicker wires make the mesh last longer and handle heavy loads. They also use more metal, which raises the price. Thinner wires cost less and work for lighter jobs, but they may not last as long.

- Thicker wires give you more strength and a longer lifespan.

- Thicker wires also reduce the open area, which can slow down screening.

- Thinner wires save money but may wear out faster.

You want to pick a wire diameter that matches your needs. If you go too thick, you pay extra for strength you might not need. If you go too thin, you may have to replace the mesh sooner.

Micron Rating And Application Needs

Micron rating tells you how small the particles are that your mesh can catch. This number is important for jobs like liquid filtration or fine screening. The smaller the micron rating, the finer the mesh, and the higher the woven wire mesh price.

Here’s a quick look at how micron rating and other specs fit different jobs:

| Feature | Description |

|---|---|

| Material | High quality stainless steel wire |

| Wire thickness | 220micron, 250micron, 280micron, 300micron |

| Usage | Liquid filter sieve |

| Advantages | Easy cleaning, stable filter effect, corrosion resistance, high strength |

| Applications | Chemical screening, food industry, acid/alkali filtration, building fences |

You can also find mesh with a 100-micron wire thickness for protection and filtration in many settings.

When you match the micron rating to your application, you get the best screening efficiency. You avoid paying for features you do not need, and you make sure your mesh works well for your job.

Remember: The right mesh specs help you control both performance and costs.

Weave Pattern And Manufacturing Process

Plain Weave Vs. Twill Weave

When you look at woven wire mesh, you will notice different weave patterns. The two most common are plain weave and twill weave. Each pattern changes how the mesh works and how much you pay.

- Plain weave is the simplest style. Each wire goes over one and under one. This pattern gives you a flat surface and even openings. Plain weave mesh usually costs less. It works well for most basic screening jobs.

- Twill weave is a bit more complex. Each wire goes over two and under two. This makes the mesh stronger and more flexible. Twill weave mesh costs more than plain weave. You might choose twill weave if you need extra strength or if your mesh will face heavy use.

You should pick the weave that matches your job. If you need a tough mesh that lasts a long time, twill weave can be worth the higher price. For simple jobs, plain weave saves you money.

Complex Patterns And Custom Orders

Sometimes, your project needs more than just plain or twill weave. You might need a special pattern or a custom size. Complex patterns, like Dutch weave or reverse Dutch weave, use different wire thicknesses or special weaving steps. These patterns help with fine filtration or unique screening needs.

Custom orders let you choose the exact mesh size, wire diameter, and weave pattern. This gives you a mesh that fits your equipment perfectly. However, custom and complex patterns take more time and skill to make. This extra work increases the price.

Note: The more complex the pattern or the more unique your order, the higher the cost. Custom mesh is great for special jobs, but you should only order it if you really need it.

Production Complexity And Cost

The way manufacturers make your mesh also affects the price. Some jobs are simple, while others need careful work and special machines. Here’s a quick look at what can change the cost:

| Factor | Description |

|---|---|

| Material | Stainless steel, carbon steel, galvanized steel, and aluminum all have different costs. |

| Mesh Size | Smaller mesh sizes need more precision and material, which raises the price. |

| Wire Diameter | Thicker wires use more metal and make production harder, so they cost more. |

| Weave Pattern | Complex patterns like twill and Dutch weave are harder to make and cost more. |

| Quantity | Buying in bulk usually lowers the price per piece. |

If you want to keep costs down, choose standard patterns and sizes. When your job needs something special, be ready to pay a bit more for the extra work. Always talk with your supplier about what you need. This helps you get the right mesh without spending too much.

Order Quantity, Customization, And Price

Bulk Orders Vs. Small Runs

When you buy woven wire mesh, the number of pieces you order changes the price you pay for each one. If you order a large quantity, you usually get a lower price per unit. This happens because the factory can set up machines once and make many pieces without stopping. You save money on setup and labor costs.

If you only need a small run, the price per piece goes up. The factory still needs to set up the machines and prepare the materials, but they spread those costs over fewer items. You end up paying more for each piece. Bulk orders help you save, especially if you know you will use a lot of mesh over time.

Tip: If you can plan ahead and order in bulk, you can lower your costs and avoid paying extra for small batches.

Custom Sizes And Shapes

Sometimes, you need wire mesh that fits a special space or does a unique job. Custom sizes and shapes can help, but they also raise the price. When you ask for something different from the standard, the factory must spend more time and effort to make it.

Here are some reasons why custom mesh costs more:

- The factory may need to use special parts or tools.

- Unique shapes or profiles take extra work to design and cut.

- Some jobs need outside processes, like special coatings or treatments.

- Small custom orders cost more per piece because setup and labor do not spread out over many items.

If you want to control your budget, try to use standard sizes and shapes when possible. Custom mesh is great for special projects, but you should only choose it when you really need it.

Lead Times And Minimum Quantities

Lead time means how long it takes to get your order. Minimum order quantity is the smallest amount you must buy. Both of these can change the price you pay.

- If you need your mesh fast, you might pay extra for rush shipping or quick production.

- Some suppliers set a minimum order size. If you order less than this, you may pay a higher price per piece.

- Labor costs go up when workers must process and cut small orders.

- If you need special paperwork or documentation, this can add to your total cost.

- Choosing mesh that is already in stock can save you money and shorten your wait time.

Note: Planning ahead helps you avoid rush fees and lets you order the right amount for the best price.

Balancing your order size, customization, and timing helps you get the most value. Think about what you really need, and talk with your supplier about the best options for your project.

Additional Features And Surface Treatments

Galvanized And Coated Mesh

Some wire mesh looks shiny or has a special finish. This is because it has a coating, like galvanization. Galvanized mesh has a zinc layer on top. The zinc acts like a shield. It keeps water and air away from the metal. This helps stop rust and corrosion. If you use mesh outside, galvanized mesh is a good choice. It works well in rain, snow, or humid places.

Hot-dipped galvanized mesh has a thick zinc layer. People also call it hardware cloth. This type is very strong and tough. You can use it in gardens or on building sites. The thick zinc means you do not need to replace it often. Even though it costs more at first, it saves money later.

There are other coated meshes too. Some have plastic or powder coatings. These coatings add color or protect against chemicals. They make the mesh last longer in harsh places. Coated mesh costs more, but it works better and looks nicer.

Tip: For both indoor and outdoor jobs, galvanized or coated mesh gives you good value and lasts longer.

Edge Preparation And Accessories

You can pick special edge treatments for your mesh. Edge preparation means how the edges are finished. Some meshes have welded or folded edges. Others have frames around them. These features stop the edges from fraying. They also make the mesh safer to touch.

You can also add accessories. These include hooks, fasteners, or mounting frames. Accessories make it easier to install the mesh. They help the mesh fit better in your equipment. Adding these extras makes your work safer and faster. But each extra thing adds to the price.

Here are some common options:

- Welded or folded edges for safety

- Custom frames for easy mounting

- Clips, hooks, or fasteners for quick setup

Think about your work area. If you move or clean the mesh a lot, these features save time and effort.

Durability And Long-Term Value

Extra features help your mesh last longer. Galvanized and coated mesh can handle bad weather and heavy use. You do not need to replace it as often. This saves money over time. Edge treatments and accessories also help your mesh work better and last longer.

Let’s look at how these features help:

| Feature | Benefit | Price Impact | Best For |

|---|---|---|---|

| Galvanized coating | Stops rust and corrosion | Medium increase | Outside, wet places |

| Plastic/powder coating | Resists chemicals, adds color | Higher increase | Food, chemical factories |

| Edge preparation | Safer, easier to handle | Small increase | Lots of handling, safety |

| Accessories | Easy to install | Changes | Custom setups, quick swaps |

Note: Pick features that match your real needs. If you work in tough places, coatings and accessories are worth it. For simple jobs, plain mesh may be enough.

Choosing the right features helps your mesh work well and saves money in the long run.

Comparing Woven Wire Mesh Price In The Market

Woven Vs. Welded Wire Mesh

You might wonder if you should choose woven or welded wire mesh for your screening job. Both types have their own price points and benefits. Here’s what you need to know:

- Woven wire mesh usually costs less at first. It works well for temporary setups or lighter jobs.

- Over time, you may spend more on repairs with woven mesh, especially if you use it in tough conditions.

- Welded wire mesh costs more upfront. The wires are joined together at every crossing, which makes it stronger.

- Welded mesh lasts longer and needs less maintenance. You save money in the long run if you need something durable.

Think about your project. If you want to save money now and your job is not too heavy, woven mesh is a smart pick. If you want something that lasts and you do not want to worry about repairs, welded mesh is the better choice.

Supplier Reputation And Certifications

Choosing the right supplier matters just as much as picking the right mesh. A good supplier gives you quality products and helps you avoid problems. Here’s why reputation and certifications count:

- Trusted suppliers use better materials and offer reliable service. This helps you avoid costly mistakes.

- Suppliers with a strong reputation may charge a bit more, but you get better value and fewer headaches.

- Customer reviews and industry reputation show if a supplier delivers on time and keeps promises.

Certifications also play a big role. They show that the supplier meets important standards. Take a look at what certifications can do for you:

| Benefit of Certifications | Description |

|---|---|

| Verify consistent product quality | Ensures that the products meet quality standards every time. |

| Ensure compliance with regulations | Helps you meet both international and local rules. |

| Reduce customs clearance risks | Makes shipping and importing smoother and faster. |

| Meet project bidding requirements | Lets you join more projects that need certified products. |

| Build trust with end users | Shows buyers and users that you are working with a trusted supplier. |

When you pick a supplier with a good name and the right certifications, you get peace of mind and better results.

Requesting Accurate Quotes

Getting the right price starts with asking the right questions. You want your quote to match your needs. Here’s how you can make sure you get an accurate quote:

- Tell the supplier the exact size, weave, and finish you need.

- Ask about the quality of materials and check if the supplier has certifications like ISO or BBB.

- Find out if the supplier can handle custom orders or special requests.

Tip: The more details you give, the better your quote will fit your project. Clear communication saves time and money.

When you compare prices, look at more than just the numbers. Think about quality, service, and long-term value. This helps you choose the best woven wire mesh for your job.

Conclusion

You now understand what changes woven wire mesh price for industrial screening. Before you buy, use this checklist:

- Material quality: Choose strong materials so your mesh lasts longer.

- Metal wire specifications: Look at the wire thickness and mesh size you need.

- Weave type: Pick the weave that fits your job best.

- Coating and finish: Get the right coating to protect your mesh.

It is important to pick a trusted manufacturer. ANPENG checks quality carefully and designs products that last longer and work better. ANPENG makes woven wire mesh, self-cleaning screens, and polyurethane screens. Contact ANPENG for expert help and solutions made for your project.

FAQ

What is the difference between mesh count and aperture size?

Mesh count tells you how many openings fit in one inch of mesh. Aperture size shows how wide each opening is. Both help you pick the right mesh for your job.

Can I use woven wire mesh outdoors?

Yes, you can. Choose galvanized or stainless steel mesh for outdoor use. These materials resist rust and last longer in rain or snow.

How do I know which wire diameter to choose?

Think about your job. If you need strength, pick a thicker wire. For light jobs, a thinner wire saves money. Ask your supplier if you are unsure.

Does custom mesh cost more?

Yes, custom mesh usually costs more. Factories spend extra time and effort making special sizes or shapes. Standard mesh is cheaper if it fits your needs.

How fast can I get my order?

Lead times depend on your order size and customization. Standard mesh ships faster. Custom orders take longer. Ask your supplier for a delivery estimate.

What certifications should I look for in a supplier?

Look for ISO or similar quality certifications. These show the supplier meets industry standards. Certified suppliers often provide better products and service.