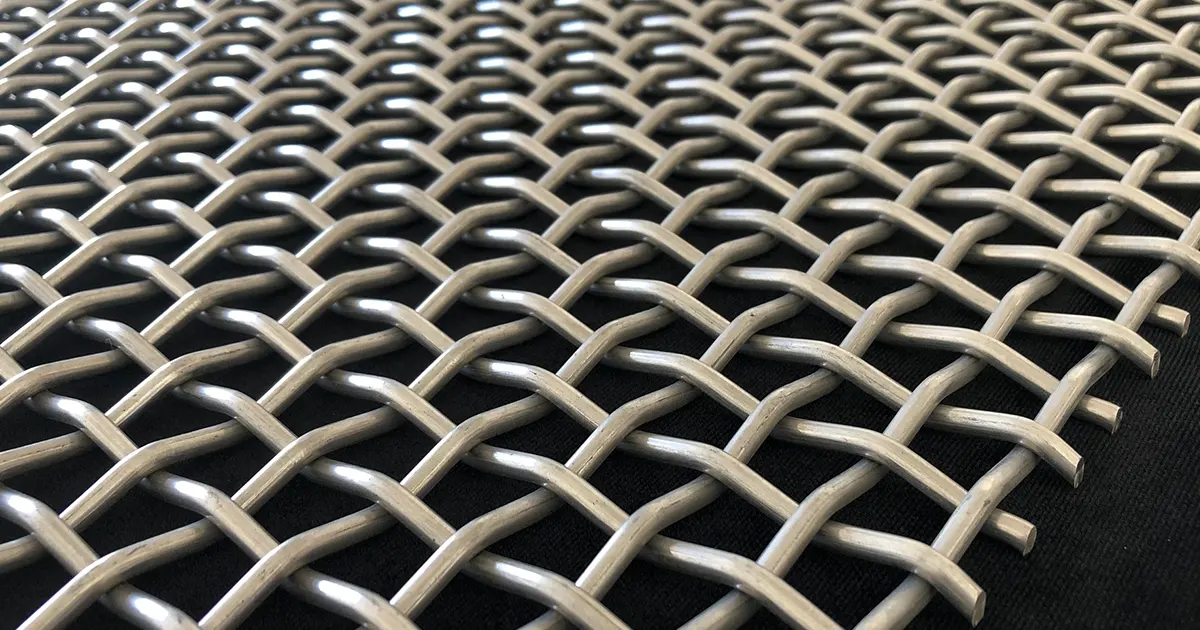

You might ask, What Is Woven Wire Mesh? In factories, woven wire mesh is special because it is made by weaving wires over and under each other. This makes a strong grid shape. The mesh is flexible. You can put it into vibrating screens in hard-working places. Many industries use woven wire mesh for vibrating screens. These include:

- Mining

- Quarry and aggregate

- Construction

- Food processing

- Agriculture

People use woven wire mesh to sort things fast and right. More people want these products now. The market for ferrous woven wire mesh is getting bigger. You will learn why this mesh is important for your work.

Key Takeaways

- Woven wire mesh is made by weaving metal wires together. This makes a strong and bendy grid. It is used in many industries.

- There are different weave patterns like plain, twill, and Dutch. Each pattern has special benefits for certain jobs.

- Woven wire mesh is chosen because it is flexible. It can fit on bumpy or uneven surfaces. Rigid welded mesh cannot do this.

- To pick the right mesh, you need to think about a few things. These include the size of the holes, the thickness of the wire, and the type of material. This helps match your screening needs.

- Self-cleaning screens work well with wet or sticky stuff. They help stop clogging and make work faster.

- Woven wire mesh gives very accurate screening. It helps sort materials by size very well.

- The mesh can last longer and resist wearing out. You can do this by picking the right wire thickness and material.

- You can also get custom mesh options. This lets you change the mesh to fit your own industrial needs.

What Is Woven Wire Mesh?

Definition for Screening

Woven wire mesh is made by weaving metal wires together. The wires go over and under each other. This makes a grid with square or rectangle openings. People use woven wire mesh in vibrating screens. It helps separate rocks, minerals, and other things by size. The mesh works well in mining, quarry, recycling, and construction.

There are different standards for wire mesh in screening. Here are some common ones:

| Standard | Description |

|---|---|

| ASTM E11 | Used for checking particle size in screening. |

| ASTM E2016 | Sets rules for using wire mesh to measure particle size. |

| ASTM E437 | Covers square mesh, sets grades by mesh count and wire thickness. |

| ISO 9044:1999 | Gives rules for opening size and grade using metric units. |

| PR-W-360A | Used by federal groups, lists types and tolerances for wire mesh. |

These standards help you choose the right mesh for your job. They explain words like aperture, mesh, and square mesh. Aperture means the size of the opening. Mesh means how many wires are in one inch. Square mesh has the same number of wires in both directions.

Construction and Patterns

Woven wire mesh starts with metal wires, often steel. The wires are woven together in a pattern. This makes the mesh strong and flexible. You can pick from different weave patterns. Each pattern has its own benefits for screening.

- Plain weave: Wires cross over and under each other. This makes even openings. It gives good strength and stability.

- Twill weave: Wires cross over two and under two. This makes a diagonal look. It gives more strength for tough jobs.

- Dutch weave: Wires are packed close together. This makes a fine mesh for special filtration.

Here is a quick look at how each pattern works:

| Weave Pattern | Characteristics | Applications |

|---|---|---|

| Plain Weave | Even openings, strong and stable | Industrial screening, covers |

| Twill Weave | Diagonal look, extra strength | Heavy-duty screening, sieves |

| Dutch Weave | Tight weave, fine filtration | Special filtration systems |

You can also find slotted mesh. Slotted mesh helps material move better and stops clogging. You can pick the wire thickness and pattern for your needs. Thicker wires make the mesh last longer in hard jobs.

Tip: You can ask for custom mesh patterns and wire sizes. This helps your screening machine work better for your material.

Flexibility vs. Welded Mesh

Woven wire mesh is different from welded mesh. Woven wire mesh bends easily. You can shape it to fit curved or uneven surfaces. Welded mesh is stiff. It does not bend or fit rough surfaces.

Here is a simple table to show the difference:

| Type of Mesh | Flexibility and Adaptability |

|---|---|

| Woven Wire Mesh | Bends; fits uneven and curved surfaces |

| Welded Wire Mesh | Stiff; does not fit rough surfaces |

Woven wire mesh is the best choice for many screening jobs. You can use it where the screen deck is not flat. The mesh can handle shaking and hits without breaking.

Woven wire mesh stands out because it is:

- Flexible and strong

- Made with careful weaving

- Able to fit your screening needs

- Has many patterns for different jobs

You can use woven wire mesh for tough screening in mining, quarry, recycling, and construction. The mesh gives you strength, flexibility, and accuracy. It lasts long and works well in vibrating screens.

How Woven Wire Mesh Is Made

Weaving Process

You might wonder how woven wire mesh gets its strength and accuracy. The process starts with careful setup. First, workers load spools of wire onto a creel. They run these wires through tensioning rollers and a beaming reed. This step keeps the wires straight and tight. Next, they wind the wires onto a warp beam, making sure each wire lines up just right.

After that, each wire goes through heddle frames and a reed. This threading step is important. It keeps the mesh openings even and the pattern correct. Once everything is in place, the assembly moves to a weaving loom. The loom weaves the wires over and under each other. Machines keep the tension steady, so the mesh stays flat and strong. The process repeats until you get a full sheet of mesh.

Note: Automated looms help make the mesh more consistent and precise. This means you get reliable screening results every time.

Different weaving styles change how the mesh works. Plain weave gives you strength and stability. Twill weave adds flexibility for finer screens. Dutch weave creates tight openings for special filtration jobs. The right weaving method helps you match the mesh to your screening needs.

Crimping Methods

Crimping shapes the wires before weaving. This step locks the wires in place and keeps the mesh openings accurate. You can choose from several crimping methods, each with its own benefits for industrial screening.

Pre-Crimped

Pre-crimped mesh means workers shape the wires before weaving. This method keeps the wires spaced evenly and locks them at each crossing. You get a mesh that holds its shape and stands up to heavy use.

Lock Crimp

Lock crimp mesh uses a special bend at each crossing. This locks the wires tightly together. You get a stable mesh that keeps its openings, even with coarse wire and large openings.

Double Crimp

Double crimp mesh bends both wires at every crossing. This makes the mesh sturdy and helps it hold tension. It works well for lighter screens that still need strength.

Flat Top

Flat top mesh has crimps only on the bottom wire. The top stays smooth. This design lets material move across the screen easily and reduces wear.

Here’s a quick look at the main crimping methods:

| Crimping Method | Advantages |

|---|---|

| Pre-Crimped | Keeps wires spaced evenly, locks mesh shape |

| Lock Crimp | Holds openings steady, great for coarse specs |

| Double Crimp | Strong and sturdy, holds tension in lighter screens |

| Flat Top | Smooth surface, less wear, easy material flow |

Materials Used

You need the right material for tough screening jobs. Most industrial woven wire mesh uses these metals:

- Stainless Steel – Strong, flexible, and resists rust. Great for wet or abrasive materials.

- Brass – Good for conductivity, but less common in heavy-duty screens.

- Copper – Offers excellent conductivity, but can corrode.

- Aluminum Alloys – Lightweight and resists corrosion.

- Molybdenum and Tungsten – Used for special high-heat or tough jobs.

| Material | Properties |

|---|---|

| Stainless Steel | Strength, flexibility, corrosion resistance |

| Brass | Good conductivity, moderate corrosion resistance |

| Copper | Excellent conductivity, prone to corrosion |

| Aluminum Alloys | Lightweight, good corrosion resistance |

You can pick the best material based on your screening needs. Stainless steel is the top choice for most mining, quarry, and recycling screens. It lasts long and handles tough conditions. ANPENG offers woven wire mesh in these materials to match your job.

Tip: Always match the mesh material to your feed material and screening environment. This helps your screens last longer and work better.

Woven Wire Mesh Types

When you look at industrial screening, you’ll find several main types of woven wire mesh. Each type works best for certain jobs in mining, quarry, aggregate, recycling, and construction. Let’s break down the different types of mesh you’ll see on vibrating screens.

Plain Weave

Plain weave mesh is the most common type you’ll use for industrial screening. You get a simple pattern where each wire goes over and under the next one. This creates square openings that stay even across the whole panel. You’ll notice this mesh offers good strength and stability, making it a reliable choice for sorting rocks, minerals, and other bulk materials.

You can use plain weave mesh for general screening tasks. It handles most feed materials and works well in tough environments. You’ll see it on vibrating screens in quarries and mines. The mesh keeps its shape and gives you accurate results.

Tip: If you need a mesh that’s easy to install and replace, plain weave is a smart pick. ANPENG offers plain weave mesh in many sizes to match your screen deck.

Here’s a quick look at how plain weave compares to twill weave:

| Feature | Plain Weave | Twill Weave |

|---|---|---|

| Weave Structure | Simple alternating over and under pattern | Over two, under two pattern |

| Strength | Basic strength, suitable for general use | Superior strength, optimal load-bearing |

| Particle Retention | Standard particle retention | Improved retention with finer specs |

| Applications | Versatile, used in many industries | Best for high-precision filtration |

Twill Weave

Twill weave mesh gives you extra strength and flexibility. In this type, each wire goes over two and under two wires. You’ll see a diagonal pattern that stands up to heavy loads and tough screening jobs. Twill weave mesh works well when you need finer openings or higher durability.

You might choose twill weave mesh for screening smaller particles or when your feed material is abrasive. The mesh holds up under pressure and keeps its openings tight. You’ll find twill weave on screens that need to last longer and handle more stress.

- Twill weave mesh is great for high-precision jobs.

- You get better particle retention and smoother operation.

- ANPENG supplies twill weave mesh for demanding screening tasks.

Crimped Mesh

Crimped mesh stands out because of its special wire shaping. Before weaving, workers crimp the wires to lock them in place. This keeps the mesh openings accurate and adds stability. You’ll see several crimp styles, such as plain crimp, lock crimp, double crimp, and flat top crimp.

Crimped mesh works best for heavy-duty screening. It handles coarse materials and resists wear. You can pick from different types of mesh crimping to match your job:

- Plain crimp: Simple bends for basic stability.

- Lock crimp: Tight bends for extra strength.

- Double crimp: Both wires bent for more tension.

- Flat top crimp: Smooth surface for easy material flow.

Note: Crimped mesh is perfect when you need a screen that won’t lose its shape, even with large rocks or high-impact loads.

You’ll find crimped mesh on vibrating screens in mining and aggregate plants. ANPENG offers all these types to help you get the best performance from your screening equipment.

If you want to learn more about the different types of mesh, you can ask ANPENG for advice. They’ll help you choose the right mesh for your material and screen deck.

Self-Cleaning Screens

You might run into problems with traditional woven wire mesh when you screen wet or sticky materials. The mesh can clog up fast. This slows down your work and lowers your screening efficiency. That’s where self-cleaning screens come in. These screens use smart designs to keep your operation moving.

Self-cleaning screens look different from standard woven wire mesh. You’ll see wires arranged in special patterns. Some wires move or flex during operation. This movement comes from the high-frequency vibration of your vibrating screen. The wires shake and shift, which helps break up clumps and keeps the openings clear. You get less clogging and more consistent material flow.

If you deal with clay, damp sand, or recycled materials, you know how tough it is to keep your screens clear. Self-cleaning screens solve this problem by using both vibration and unique wire layouts.

Here’s what makes self-cleaning screens stand out:

- They prevent clogging with high-frequency vibration.

- The special wire patterns handle wet and sticky materials better than regular mesh.

- You get steady throughput, even when your feed is tough to screen.

Self-cleaning screens come in a few main styles. You might see harp screens, piano wire screens, or wave screens. Each type uses a different wire arrangement. For example, harp screens have straight wires running in one direction and crimped wires running the other way. This setup lets the wires move and flex, which shakes off sticky material. Piano wire screens use thin, straight wires that vibrate easily. Wave screens use a wavy pattern to keep material moving.

You can use self-cleaning screens in mining, quarry, aggregate, recycling, and construction. They work best when you need to screen wet, sticky, or hard-to-handle materials. You’ll see better efficiency and less downtime for cleaning or replacing clogged panels.

Here’s a quick comparison:

| Feature | Traditional Woven Wire Mesh | Self-Cleaning Screens |

|---|---|---|

| Handles Wet/Sticky Feed | No | Yes |

| Clogging Risk | High | Low |

| Throughput Consistency | Variable | Steady |

| Maintenance Needs | Frequent | Reduced |

If you want to boost your screening efficiency, consider self-cleaning screens from ANPENG. You can choose the right style and wire size for your material and screen deck. These screens help you keep your operation running, even with the toughest feed.

Tip: Talk to your screen supplier about self-cleaning options if you notice frequent clogging or downtime. The right screen can save you time and money.

Wire Mesh Specifications

Aperture Size

Aperture size means the width of each opening in your woven wire mesh. You measure it from the inside edge of one wire to the inside edge of the next. This number is key for screening because it decides what size particles can pass through. If you want to separate rocks or minerals by size, you need to pick the right aperture.

The shape and size of the openings matter a lot. Square openings give you a precise cut size, which helps you get accurate results. When you use mesh with the right aperture, you boost your screening efficiency. Materials move across the screen, and the right design helps them rotate and fall through faster. This means you get more material sorted in less time. Fine particles reach the screen surface quickly, so your throughput goes up.

Tip: Always match your aperture size to the cut size you need. This helps you avoid clogging and keeps your operation running smoothly.

Mesh Count

Mesh count tells you how many openings sit in one linear inch of your mesh. For example, a mesh count of 10 means there are 10 openings per inch. But here’s something important: mesh count alone does not tell you the size of the openings. The wire diameter also plays a role.

- The size of the screen openings affects how well you separate particles—not just the mesh count.

- Mesh count shows the number of openings per inch, but not their size.

- Both mesh count and wire diameter matter when you pick a screen for the best separation.

- Manufacturers, like ANPENG, offer standard mesh types to make your choice easier.

If you want to separate fine material, you might look for a higher mesh count. But always check the actual opening size to make sure it fits your needs.

Wire Diameter

Wire diameter is the thickness of each wire in your mesh. This measurement affects both the strength and the wear life of your screen. Thicker wires last longer and stand up to heavy loads, but they make the openings smaller. Thinner wires give you bigger openings, but they wear out faster.

Here’s a quick table to help you see the difference:

| Wire Gauge | Characteristics | Common Use in Screening |

|---|---|---|

| Thicker Wire | Strong, long-lasting, smaller openings | Heavy-duty, coarse screening |

| Thinner Wire | Flexible, larger openings, less durable | Fine screening, lighter loads |

If you use a lock crimp weave, you get even more strength. The wires lock together at each crossing, so the mesh resists bending and lasts longer. This design works well for tough jobs in mining and quarry screening.

Note: Always balance wire diameter with your desired opening size. Thicker wires mean longer wear life, but you may lose some open area.

Choosing the right combination of aperture size, mesh count, and wire diameter helps you get the best performance from your woven wire mesh. ANPENG can help you select the right specs for your vibrating screens, so you get reliable results every time.

Open Area

Open area is a key factor when you choose woven wire mesh for your vibrating screen. Open area means the percentage of the mesh surface that is open space. This space lets material pass through the screen. You want to get the right balance between open area and wire strength.

- A higher percentage of open area lets more material move through your screen. This boosts your throughput and helps you process more in less time.

- More open area also lowers pressure drop. Your screening machine works more efficiently because material flows easier.

- If you pick a mesh with a lot of open area, you may need to use thinner wires. Thinner wires can wear out faster, especially if you screen abrasive materials.

- You need to balance open area with durability. If you handle tough or sharp materials, you might want a mesh with a little less open area but thicker wires for longer life.

You can find the open area percentage in the mesh specifications. For example, a mesh with 60% open area means 60% of the surface is open for material to pass through. The rest is wire. If you want to boost your screening speed, look for a higher open area. If you need your mesh to last longer, choose a lower open area with thicker wires.

Here’s a quick table to help you compare:

| Open Area (%) | Throughput | Durability | Best For |

|---|---|---|---|

| High (60-70%) | High | Lower | Fast screening, soft material |

| Medium (50-60%) | Balanced | Balanced | General screening |

| Low (40-50%) | Lower | High | Abrasive, heavy material |

Tip: Always check your material type and screening goals before you pick your open area. ANPENG can help you find the right balance for your operation.

Panel Size and Tensioning

Panel size and tensioning play a big role in how well your woven wire mesh works on a vibrating screen. You need to pick the right panel size for your screen deck. If the panel is too big or too small, it will not fit right. This can cause gaps or loose spots where material can slip through.

Tensioning is just as important. You want your mesh to be drum-tight when you install it. If the mesh is loose, material can move in random ways on the screen. This makes it hard to separate your material by size. Loose mesh can also vibrate too much against the support bars. This extra movement can damage the mesh and cause your screen to fail early.

When you install a new mesh panel, always check the tension. Use the right tools to make sure the mesh is tight and flat. If you see sagging or hear rattling, stop and fix the tension. A tight mesh gives you better screening results and helps your mesh last longer.

Note: ANPENG offers custom panel sizes and tensioning systems to fit your vibrating screen. You can ask for help to get the best setup for your plant.

If you pay attention to open area, panel size, and tensioning, you will get better performance from your woven wire mesh. Your screening process will run smoother, and your mesh will last longer.

Woven Wire Mesh Benefits

Screening Accuracy

You want your screens to give you exact results. Woven wire mesh helps you sort materials by size. The mesh has even openings, so you can trust the sorting. If you pick mesh with the right opening size, you get the same cut every time. This lets you sort rocks, minerals, or aggregates just how you need.

The tight weave and strong build keep the openings steady. The mesh does not change shape when it shakes. Big pieces do not slip through by mistake. Small pieces do not stay on the screen too long. This helps you meet your quality goals and keeps your work going well.

Tip: Pick mesh with the right opening size and wire thickness for your material. You will get better sorting and less waste.

Throughput and Efficiency

You want your screens to work fast and handle lots of material. Woven wire mesh helps you move more material quickly. The mesh has lots of open space, so things pass through fast. You can process more tons each hour and keep your work moving.

Special mesh patterns and the right opening size stop clogging. Material flows easily, so you spend less time fixing blockages. The mesh also sorts materials better, which is important for big jobs in mining and quarry work.

Here is a table that shows how woven wire mesh helps your screening:

| Benefit | Explanation |

|---|---|

| Higher screening capacity | More open space lets particles pass through better. |

| Better material stratification | Helps sort materials, which is important for big jobs. |

| Reduced blinding and pegging | Special patterns and right openings keep flow and stop clogs. |

| Predictable maintenance | You can see wear and plan repairs, so you avoid surprise stops. |

| Easy integration and replacement | Mesh panels fit into your system easily, so you can upgrade fast. |

You can put in new mesh panels quickly and swap them out when needed. This keeps downtime short and helps you keep working. ANPENG has mesh that fits most screens, so you can upgrade easily.

Wear Life

You want your screen panels to last a long time. Woven wire mesh is tough, especially if you pick the right wire thickness and material. The mesh stands up to rough rocks and minerals, so you use it longer before changing it.

Woven wire mesh wears in a way you can predict. You can plan repairs and avoid sudden problems. Here is a table that shows how long different screen panels last:

| Material | Service Life (Months) | Wear Resistance Comparison |

|---|---|---|

| Rubber Screen Panel | 3-6 | Baseline |

| Polyurethane Screen Panel | 6-12 | 3-5 times longer than rubber |

Woven wire mesh works well in hard jobs. You can pick stainless steel mesh for wet or rough places. This mesh lasts longer and fights rust. If you choose mesh with the right specs, you save money and keep your work running.

Note: Check your mesh often and keep it tight to make it last longer. ANPENG can help you pick the best mesh for your screens.

Easy Installation

You want your screening equipment to run smoothly with as little downtime as possible. Woven wire mesh makes installation simple and fast. You can cut and shape the mesh to fit your vibrating screen deck. This means you can handle both small and large screening jobs without extra hassle. The mesh works well with standard sheet metal tools, so you do not need special equipment or training.

You can order woven wire mesh panels in custom sizes. You pick the opening size, weave type, and wire thickness that match your screening needs. This customization helps you get the right fit for your machine. The flexible structure of woven wire mesh lets you install it on flat or curved decks. The mesh bends without losing strength, so you can use it in many different setups.

Here’s a quick look at why installation is easier with woven wire mesh compared to other screen media:

| Advantage | Description |

|---|---|

| Customization | You can tailor the mesh for opening size, weave type, and wire thickness. |

| Flexibility | The mesh bends and fits many shapes and deck designs without losing strength. |

You can also form the mesh into different shapes. This helps when you need to screen materials in tight spaces or on unique equipment. The mesh suits both small pilot plants and large-scale mining operations. You can swap out worn panels quickly, which keeps your downtime low and your productivity high.

Tip: If you want to speed up maintenance, choose woven wire mesh panels from ANPENG. You get panels that fit your screen deck and are easy to replace.

Versatility

Woven wire mesh stands out because you can use it in many industrial screening jobs. You see it in mining, quarry, aggregate, recycling, and construction plants. The mesh handles heavy loads and tough materials, so you can trust it in harsh environments.

You can pick from many wire diameters, opening sizes, and weave patterns. This lets you match the mesh to your material and screening goals. The mesh works well for both dry and wet screening. It resists wear and handles abrasive materials, which makes it a smart choice for high-impact jobs.

Here’s why woven wire mesh is so versatile for industrial screening:

- You can use it for primary, secondary, or final screening.

- The mesh fits many types of vibrating screens and deck sizes.

- You can screen everything from large rocks to fine sand.

- The mesh stands up to high loads and resists corrosion in tough conditions.

Many industries choose woven wire mesh because it adapts to changing needs. You can upgrade your screen panels as your material or process changes. The mesh’s high-tensile strength means it lasts longer, even in demanding jobs.

Note: ANPENG offers woven wire mesh in many specs, so you can find the right panel for your plant. If you need help, you can ask for advice on the best mesh for your screening application.

Industrial Screening Applications

Mining

You see woven wire mesh used everywhere in mining. When you need to separate rocks, ores, or minerals by size, this mesh does the job. You load heavy material onto a vibrating screen. The mesh sorts it fast and keeps the process moving. You want your mesh to last, even with sharp or rough rocks. That’s why you pick high carbon steel or 65Mn material for extra wear resistance.

Here’s a quick look at what you need from your mesh in mining:

| Application Type | Performance Requirements |

|---|---|

| Particle sizing and separation in mining | Consistency and durability for heavy materials |

Woven wire mesh gives you flexibility. You can fit it to many types of screening equipment and ore. You get precise openings, so your particle separation stays accurate. You also save time because the mesh is easy to install and replace. This means less downtime and more production.

| Key Benefits of Woven Wire Mesh in Mining Operations | Description |

|---|---|

| Flexibility and Adaptability | Fits different screening machines and ore types |

| Precise Aperture Sizes | Gives you accurate and steady separation |

| Superior Wear Resistance | Lasts longer with tough materials |

| Easy Installation and Replacement | Quick changes keep your plant running |

Tip: If you want a mesh that stands up to tough jobs, ask ANPENG about their mining-grade woven wire mesh panels.

Quarry & Aggregate

In quarry and aggregate plants, you deal with large stones, gravel, and sand. You need a screen that can handle heavy loads and keep working day after day. Woven wire mesh is a top choice here. It sorts material by size, so you get the right product for your customers.

You want your mesh to be strong and stable. The mesh must resist wear from sharp stones and constant vibration. You also need it to fit your screen deck perfectly. With woven wire mesh, you can pick the opening size and wire thickness that matches your job. This helps you get the best results, whether you’re making road base, concrete mix, or fine sand.

- Woven wire mesh keeps your screening accurate.

- You can change panels quickly when they wear out.

- The mesh works well with both dry and wet materials.

Note: ANPENG offers custom mesh panels for quarry and aggregate screens. You can get the right fit for your plant and material.

Recycling

Recycling plants use woven wire mesh to sort and clean materials like crushed concrete, asphalt, and scrap metal. You want to separate these materials by size before they move to the next step. The mesh stands up to sharp edges and heavy impacts. It also handles sticky or damp material without clogging.

You need a mesh that is easy to clean and replace. Woven wire mesh lets you keep your operation running with less downtime. You can use self-cleaning mesh styles if you deal with wet or sticky feed. This helps you avoid blockages and keeps your throughput steady.

- Woven wire mesh helps you recover more usable material.

- The mesh lasts longer, even with tough recycled products.

- You can trust the mesh to keep your screening process efficient.

If you want to boost your recycling plant’s performance, look for woven wire mesh panels from ANPENG. You get panels that fit your equipment and help you meet your production goals.

Construction

You work in construction and building, so you know how important it is to sort materials quickly and accurately. Woven wire mesh plays a big role in this industry. You see it used on vibrating screens at concrete plants, sand pits, and demolition sites. The mesh helps you separate gravel, sand, crushed stone, and recycled concrete. This makes your job easier and keeps your projects on track.

When you use woven wire mesh in construction and building, you get strong and reliable screening. The mesh stands up to heavy loads and rough materials. You can trust it to keep working, even when you feed it sharp rocks or broken concrete. The mesh does not clog easily, so you spend less time cleaning and more time producing.

You can choose different mesh sizes and wire diameters for your job. If you need to screen fine sand for concrete, you pick a mesh with small openings. If you want to sort large stones for road base, you use a mesh with bigger openings and thicker wires. This flexibility helps you match the mesh to your material and your equipment.

Here are some ways woven wire mesh helps you in construction and building:

- It sorts aggregates for concrete and asphalt production.

- It separates debris from usable material during demolition recycling.

- It screens sand and gravel for road and foundation work.

- It handles both dry and wet materials without losing strength.

Tip: If you want to boost your plant’s efficiency, try custom mesh panels from ANPENG. You can get panels that fit your screen deck and your material specs.

You also save money with woven wire mesh. The panels last a long time, so you do not need to replace them often. When you do need a new panel, you can install it quickly and get back to work fast. The mesh fits most standard vibrating screens, so you do not need special tools or training.

Woven wire mesh gives you the accuracy and speed you need for construction and building projects. You can trust it to keep your screening process running, no matter what material you feed it.

Wet & Sticky Materials

Screening wet and sticky materials can be a real challenge. You know how fast regular screens can clog when you feed them damp sand, clay, or recycled materials. Woven wire mesh, especially self-cleaning types, helps you solve this problem.

Self-cleaning woven wire mesh uses special wire patterns. Some wires move or flex as your vibrating screen runs. This movement shakes off sticky material and keeps the openings clear. You get steady material flow and less downtime for cleaning.

You can use self-cleaning mesh for:

- Wet sand and gravel

- Clay-rich aggregates

- Recycled concrete with moisture

- Compost or soil with organic matter

Here’s a quick table to show how self-cleaning mesh compares to standard mesh:

| Feature | Standard Mesh | Self-Cleaning Mesh |

|---|---|---|

| Handles wet feed | No | Yes |

| Clogging risk | High | Low |

| Throughput consistency | Variable | Steady |

If you want to keep your plant running, switch to self-cleaning mesh from ANPENG. You will see less blinding and pegging, which means more material passes through your screens. You also spend less time on maintenance.

Note: Always match your mesh type to your material. If you screen wet or sticky feed, self-cleaning woven wire mesh is your best choice.

Woven wire mesh helps you handle tough screening jobs in all conditions. You get reliable performance, even when your material is hard to process.

Choosing Woven Wire Mesh

Picking the right woven wire mesh is important for your plant. The mesh you choose should match your material, machine, and work area. Use this checklist to help you pick the best mesh.

Selection Checklist

Think about these things when you pick woven wire mesh:

Cut Size

Decide what size pieces you want to separate. Cut size means the opening in the mesh. This lets certain materials go through. If you need exact sizing, pick a mesh with the right opening.

Wire Diameter

Think about how strong you need your mesh to be. Thicker wires last longer and hold heavy loads. But thick wires have less open space. Thinner wires give you more open area and better flow. But they wear out faster. Try to balance strength and how much material you want to move.

Material Type

Pick a mesh material that fits your job. Stainless steel is good for wet or rusty jobs. Galvanized steel works for most uses. If you use harsh chemicals or high heat, choose a mesh that can handle it.

Deck Size

Measure your screen deck before you buy mesh. The mesh panel must fit your machine. If it is too small or too big, it will not work well. You could also damage your machine.

Throughput

Think about how much material you want to screen each hour. If you want to move more material, pick a mesh with more open space. Make sure your mesh can handle your work speed.

Moisture & Abrasion

Check if your material is wet, sticky, or rough. Wet or sticky stuff can clog normal mesh. Rough material wears mesh out faster. Pick a mesh that can handle your material.

Here is a table to help you compare what to look for:

| Factor | Description |

|---|---|

| Material | Pick rust-proof mesh for tough jobs. |

| Wire Diameter | Thick wires are strong, thin wires bend more. |

| Aperture Size | Changes how fast material moves and how well you sort. |

| Surface Treatment | Coatings like zinc or PVC make mesh last longer. |

| Environmental Conditions | Think about water, chemicals, and heat. |

| Application Needs | Match mesh to your main job, like sorting or support. |

Tip: If you need help, ask experts like ANPENG. They can help you pick the right mesh.

When to Use Self-Cleaning or PU Mesh

Sometimes, regular woven wire mesh is not enough. If you work with wet, sticky, or rough materials, you may need a different screen. Self-cleaning screens and polyurethane (PU) mesh can help with special problems.

- Use self-cleaning screens for wet or sticky materials. The wires move and shake off clogs. This keeps your work going.

- Pick PU mesh for fine, rough, or rusty materials. PU mesh lasts longer and does not wear out fast.

Here is a table to help you choose:

| Screening Media | Best For |

|---|---|

| Polyurethane Screens | Fine, rough, or rusty materials |

| Self-Cleaning Screens | Wet, sticky materials that clog screens |

| Metal Screens | Heavy-duty jobs with lots of impact |

Note: If your mesh clogs or wears out fast, try self-cleaning or PU mesh. This can help your plant run better.

Manufacturer Consultation

You do not have to pick mesh by yourself. Experts at ANPENG can help you choose the right mesh for your plant. Tell them about your material, cut size, wire thickness, deck size, how much you want to screen, and your work area. They will help you find the best mesh for your job. They can also help with air or water filtration if you need it.

Call ANPENG for advice and custom mesh. The right mesh helps your plant run smoothly.

Screen Media Comparison Table

Woven Wire vs. Self-Cleaning vs. PU Mesh vs. Urethane Panels

When you choose screen media for your vibrating screens, you want to know how each type performs. Each option—woven wire mesh, self-cleaning screens, PU mesh, and urethane panels—has its own strengths. Let’s break down the key differences so you can pick what works best for your plant.

Choosing the right screen media can help you boost throughput, cut downtime, and save on maintenance. You want your screens to last and keep your operation running smoothly.

Here’s a side-by-side look at how these four types compare for industrial screening:

| Feature | Woven Wire Mesh | Self-Cleaning Screens | PU Mesh | Urethane Panels |

|---|---|---|---|---|

| Clogging Resistance | Prone to clogging with wet or sticky material; needs frequent cleaning | Designed to reduce clogging; wires flex to clear blockages | Can clog with sticky feed; needs occasional cleaning | May clog with fine or damp material; manual cleaning required |

| Throughput | High when clean; drops as clogging builds up | Keeps flow rates steady; less downtime from blockages | Good for heavy-duty loads; can slow if clogged | Handles tough loads; throughput drops if blinding occurs |

| Wear Life | Good with right wire size; wears faster with abrasive feed | Similar to woven wire; less wear from reduced cleaning | Excellent; absorbs impact and resists abrasion | Very high; best for abrasive and heavy-duty screening |

| Maintenance | Needs regular checks and cleaning; easy to replace | Less manual cleaning; fewer repairs; lower maintenance costs | Occasional cleaning needed; panels last long | Low maintenance; panels last longest but are heavier |

| Installation | Quick and simple; fits most vibrating screens | Easy to install; fits standard decks | Panels are heavier; need careful fitting | Heaviest; may need extra support for large decks |

| Cost | Lowest upfront cost; more frequent replacement | Moderate; saves money on cleaning and downtime | Higher initial cost; lasts longer | Highest cost; longest service life |

| Best For | General screening; dry, non-sticky material | Wet, sticky, or hard-to-screen material | Heavy-duty, abrasive, or high-impact loads | Extreme wear, high-impact, or long service intervals |

You might notice that woven wire mesh gives you high accuracy and easy installation. It works best when your material is dry and not sticky. If you deal with wet or sticky feed, self-cleaning screens help you avoid clogs and keep your plant running. PU mesh and urethane panels shine in heavy-duty jobs. They last longer and handle tough loads, but they can still clog with sticky material.

If you want to cut downtime and save on repairs, self-cleaning screens from ANPENG can help. For the toughest jobs, PU mesh and urethane panels give you the longest wear life.

Think about your material, your throughput goals, and your maintenance needs. The right screen media makes a big difference in your plant’s performance.

Conclusion

Now you understand how woven wire mesh helps with screening in factories. You learned about the different types, sizes, and why it is useful for mining, quarry, recycling, and building work. Picking the right mesh helps your machines work better and keeps your plant running well. ANPENG makes woven wire screens and can make special ones just for you. If you want to improve your screens, ask for a price and tell them your material, opening size, wire thickness, panel size, how wet or rough your material is, how much you need to screen, and your screen type.

FAQ

What is the main advantage of woven wire mesh for vibrating screens?

You get high screening accuracy and fast material flow. Woven wire mesh gives you even openings and strong panels. This helps you sort rocks, minerals, and aggregates quickly in mining, quarry, and recycling plants.

How do I choose the right mesh size for my screen?

First, check the cut size you need for your material. Then, match the aperture size and wire diameter. If you need help, ANPENG can recommend the best mesh for your vibrating screen.

Can woven wire mesh handle wet or sticky materials?

Yes, but you should use self-cleaning woven wire mesh for wet or sticky feed. The special design helps prevent clogging and keeps your screening line running smoothly.

How long does woven wire mesh last in industrial screening?

Service life depends on your material and wire thickness. You can expect several months of use with proper tension and maintenance. Stainless steel mesh from ANPENG lasts longer in wet or abrasive conditions.

Is woven wire mesh easy to install and replace?

Yes! You can cut and shape panels to fit your screen deck. Most mesh panels from ANPENG fit standard vibrating screens. You can swap them out quickly to reduce downtime.

What materials are available for ANPENG woven wire mesh?

You can choose stainless steel, high-carbon steel, or other alloys. Stainless steel resists rust and works well with wet or abrasive materials. High-carbon steel offers extra strength for heavy-duty jobs.

When should I use polyurethane (PU) or self-cleaning screens instead of woven wire mesh?

Switch to PU mesh for very abrasive or fine materials. Use self-cleaning screens for wet, sticky, or hard-to-screen feed. ANPENG offers both options to help you solve clogging and wear problems.

Can I get custom sizes or patterns for my screening plant?

Yes, you can! ANPENG makes custom woven wire mesh panels. Just share your material type, cut size, wire diameter, deck size, and throughput needs. You get a mesh that fits your plant perfectly.